Abstract

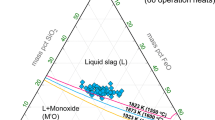

The use of foaming slag in an electric arc furnace provides a reduction in the consumption of electric energy, electrodes, and refractories in the furnace. The objective of this study is to determine the foaming index of different slags of the CaO-FeO-SiO2-MgO system, and to relate this index with the composition and viscosity of the slag and the volume of CO generated. The Factsage 8.0 software was used to simulate the determination of the viscosity of the liquid slag and the phases present in the slag at the temperature of 1650 °C. The height reached and the time of the foaming were measured by experiments carried out in an induction furnace with a MgO crucible. The generated volume of CO and the carbon consumption was calculated by mass balance through the variation of FeO between the initial and final percentages of FeO in the slag. The experimental results indicate that the best foaming conditions were achieved with slags containing 8% FeO and 22% MgO, 12% precipitated phases, ternary basicity between 1.2 and 1.4, and viscosity of 0.499 poise. The results showed that the most important parameter for obtaining a higher slag foaming index is the viscosity value.

Similar content being viewed by others

References

S. Aminorroaya-Yamini and E. Hossein, in 7th Eur. Electr. Steelmak. Conf. (Venice, 2002), pp. 2447–2456.

T. da C. Avelar, Use of Recycled MgO-C Bricks and Dolomite Sinter Fines as a Conditioner for Foaming Slag in Electric Arc Furnaces, Federal Institute of Espírito Santo, 2013. (in Portuguese)

T. A. Ávila, Slag Conditioning in an Electric Arc Furnace to Optimize Slag Foaming Conditions and Steel Refining, Federal University of Minas Gerais, 2011. (in Portuguese)

K. Ito, and R.J. Fruehan, Metall. Trans. B 20, 509 (1989).

K. Ito, and R.J. Fruehan, Metall. Trans. B 20, 515 (1989).

K. Ito, and R.J. Fruehan, I Sm 16, 55 (1989).

J. Jones, Iron Steelmak. 23, 1 (1996).

H.S. Kim, D.J. Min, and J.H. Park, ISIJ Int. 41, 317 (2001).

K.-S. Kwong, and J.P. Bennett, J. Miner. Mater. Charact. Eng. 01, 69 (2002).

K. Kwong, J. Bennett, R. Krabbe, A. Petty, and H. Thomas, in 138th Miner. Met. Mater. Annu. Meet. Exhib. (TMS 2009) (San Francisco, CA, 2009), pp. 63–70.

A. P. Luz, T. A. Ávila, P. Bonadia, and V. C. Pandolfelli, in Refract. World Forum (2011), pp. 1–8.

E.B. Pretorius, and R.C. Carlisle, Iron Steelmak. (I SM) 26, 79 (1999).

S. Seetharaman, A. Mclean, R. Guthrie, S. Sridhar, A. Waltham, Heidelberg, London, New, Y. Oxford, P. San, D. San, F. Sydney, and Tokyo, Treatise on Process Metallurgy-Volume 3, 1st ed. (Elsevier Ltd, Coventry-UK, 2014).

Z. Li, and C. Davis, Ironmaking and Steelmaking Processes (Springer International Publishing, Cham, 2016).

K.C. Mills, and B.J. Keene, Int. Mater. Rev. 32, 1 (1987).

D. Huin, Y. Ogawa, H. Gaye, and N. Tokumitsu, ISIJ Int. 33, 224 (1993).

Y.-E. Chang, C.-M. Lin, J.-M. Shen, W.-T. Chang, and W. Wu, Metals (Basel). 11, 249 (2021).

M. Liukkonen, K. Penttilä, and P. Koukkari, A Compilation of Slag Foaming Phenomenon Research: Theoretical Studies, Industrial Experiments and Modelling (VTT Technology, Espoo, 2012).

T.C. da Avelar, F.F. Grillo, E. Junca, J.L. Coleti, and J.R. de Oliveira, REM-Int. Eng. J. 71, 67 (2018).

Y. Zhang, and R.J. Fruehan, Metall. Mater. Trans. B 26, 813 (1995).

Acknowledgements

We thank FAPES, CNPq e IFES for the financial assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

da Costa Avelar, T., de Souza, R.M., Durante, T. et al. Influence of Physicochemical Properties and Chemical Composition of Slags on the Slag Foaming Index. JOM 75, 2045–2053 (2023). https://doi.org/10.1007/s11837-022-05685-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05685-3