Abstract

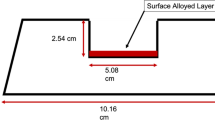

In this study, the ability to control the thickness and composition of surface alloyed layer on mild steel (produced by coating the surface of the mold with metal powders) has been demonstrated. The surface alloying process was conducted during lab-scale sand casting by coating the mold surfaces with slurries containing Ni, Cr, Fe-Si, and Fe-Mn as alloying powders. Two different compositions of surface alloying powders were tested for their level of enrichment and effect on the properties of Wrought Carbon Grade B (WCB) steel. The powder quantity per unit area of mold surface was varied to control the thickness of the surface alloyed (SA) layer between 1000 and 4000 microns; the thickness varied linearly with the amount of powder per unit area. The microstructure, composition, and phases of the alloyed layers were characterized for a few selected samples. The presence of austenite, ferrite, and limited chromium oxide was observed in the surface alloyed layers by x-ray diffraction (XRD). Limited testing of surface alloyed samples showed an increase in the hardness and corrosion resistance as compared to WCB steel substrate. These improved properties can lead to an increase in the life of the cast components with a minimal increase in the production cost.

Similar content being viewed by others

References

S. Gasteyer, Are small community water systems more at risk than other systems. On Tap (2010).

C.P. Dillon, Corrosion Resistance of Stainless Steels (CRC Press, New York, 1995).

J.R. Davies, Stainless Steels (ASM Specialty Handbook) (ASM International, Ohio, 1994).

M. Martin, S. Weber, W. Theisen, T. Michler, and J. Naumann, Int. J. Hydrogen Energy 36, 15888 (2011).

M.H. Abd Elhamid and G.V. Dadheech, US 8,834,734 B2 (2014).

J. Mazumder and J. Singh, NATOASI Ser. E Appl. Sci. 7, 297 (1986).

L. Jinlong, L. Tongxiang, and W. Chen, Mater. Lett. 171, 38 (2016).

C. Nicard, C. Allély, and P. Volovitch, Corros. Sci. 146, 192 (2019).

A. Amirsadeghi and M.H. Sohi, J. Mater. Process. Technol. 201, 673 (2008).

M. Shamanian, S.M.R.M. Abarghouie, and S.R.M. Pour, Mater. Des. 31, 2760 (2010).

J. Singh, S.S. Chatha, and B.S. Sidhu, Mater. Today Proc. 21, 1340 (2020).

M.D. Joshi, V. Kumar, I. Singh, and S.S. Hosmani, J. Tribol. 143, 1 (2021).

Q. Chen, J. Zhang, A. Huang, and P. Wei, Appl. Sci. 11, 446 (2021).

X. Cao, J. Hu, W. Huo, X. Xi, and W. Zhao, Vacuum 184, 109914 (2021).

L. Zhang, C.T. Peng, J. Shi, and R. Lu, Appl. Surf. Sci. 532, 147477 (2020).

S. Yu, Y. Wang, J. Gao, H. Hei, R. Wang, and Z. He, Surf. Rev. Lett. 27, 1950229 (2020).

N. Jeyaprakash, C.-H. Yang, M. Duraiselvam, and S. Sivasankaran, Archiv. Civ. Mech. Eng 20, 20 (2020).

D.F. MacDonald, U.S. Patent No. 3,450,189 (U.S. Patent and Trademark Office, Washington, DC, 1969).

G.S. Revankar, U.S. Patent No. 5,879,743 (U.S. Patent and Trademark Office, Washington, DC, 1999).

K. Rane, M. Beining, S. Behera, A. Kordijazi, A. Kumar, and P. Rohatgi, Int. J. Metalcast. 16(1), 359 (2022).

A. Kordijazi, M. Beining, K. Rane, S. Behera, and P. Rohatgi, Steel Res. Int. 93, 2100385 (2022).

K. Rane, S. Behera, A. Kordijazi, A. Kumar, B. Church, R. Dasgupta, and P. Rohatgi, J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-022-07462-4 (2022).

N. Srisuwan, K. Eidhed, N. Kreatsereekul, T. Yingsamphanchareon, and A. Kaewvilai, Metals 6, 26 (2016).

T. Ohmi, Y. Nakagawa, M. Nakamura, A. Ohki, and T. Koyama, J. Vac. Sci. Technol. A Vac. Surf. Film 14, 2505 (1996).

Y.N. Ko, S. Bin-Park, S.H. Choi, and Y.C. Kang, Sci. Rep. 4, 1–10 (2014).

Y. Shu, H. Chen, N. Chen, X. Duan, P. Zhang, S. Yang, Z. Bao, Z. Wu, and S. Dai, Chem. 6, 1723 (2020).

L. Wang, A. Seyeux, and P. Marcus, Corros. Sci. 165, 108395 (2020).

K. Čech-Barabaszová, A. Slíva, G. Kratošová, S. Holešová, A. Volodarskaja, T. Cetinkaya, S. Brožová, L. Kozubek, and G. Simha-Martynková, Materials 15, 5343 (2022).

M. Krishna-Kumar, R. Saravanan, R. Sellamuthu, and V. Narayanan, Mater. Today Proc. 5, 7571 (2018).

S. Sharma, P. Hiremath, M.C. Gowrishankar, and M. Shettar, Int. J. Mech. Eng. Technol. 10(1), 1235 (2019).

S.D. Cramer and B.S. Covino, ASM Handbook Corrosion (ASM International Materials Park, Ohio, 1992).

Y. Yu, S. Shironita, K. Souma, and M. Umeda, Heliyon 4, e00958 (2018).

Acknowledgements

This work was supported by the NSF WEP I/UCRC (#1540032) through the period of 2016 – 2019. The authors also extend thanks to the Advanced Analysis Facility at the University of Wisconsin-Milwaukee for their assistance with advanced characterization of the samples. The authors acknowledge the support of Badger Alloys, Inc., based in Milwaukee. for their support in the scaling of the casting process.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rane, K., Behera, S., Kordijazi, A. et al. Control of Thickness and Microstructure of Surface Alloyed Layers on Mild Steels During Sand Casting. JOM 75, 76–85 (2023). https://doi.org/10.1007/s11837-022-05581-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05581-w