Abstract

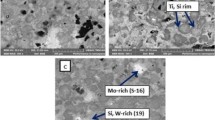

Ni-based superalloy (Inconel 718) has been widely employed in aircraft, gas turbine engines, and turbocharger rotor equipment, due to its high strength and long fatigue life, but inadequate oxidation resistance has restricted high-temperature applications. In the current study, a NiCoCrAlFe high-entropy alloy (HEA) coating was fabricated on Inconel 718 using low energy ball-milled/blended elemental powders thermally sprayed by an atmospheric plasma spraying process. The microstructural and isothermal oxidation behavior of the NiCoCrAlFe HEA bond coats at 1000°C was studied. The result revealed that the microstructure of the HEA coatings consists of dark and light phases in the lamellar structure. The dark phases are relatively hard and are oxides, while the soft phase is the HEA phases spread in the microstructure. The novel NiCoCrAlFe high-entropy bond coat exhibits a considerably low oxidation rate and slow (Al2O3) TGO formation on the surface of the bond coats at elevated temperatures and exposure for extended durations. In conclusion, the present study provides a workable approach for enhancing the oxidation resistance of Inconel 718 alloy in high-temperature conditions.

Similar content being viewed by others

References

X. Jun, C.-M. Cao, G. Ping, and L.-M. Peng, Trans. Nonferr. Metal Soc. 30, 746. https://doi.org/10.1016/S1003-6326(20)65250-5 (2020).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299. https://doi.org/10.1002/adem.200300567 (2004).

B. Cantor, I. Chang, P. Knight, and A. Vincent, Mater. Sci. Eng. A 375, 213. https://doi.org/10.1016/j.msea.2003.10.257 (2004).

J. Yu, X. Lin, J. Wang, J. Chen, and W. Huang, Appl. Surf. Sci. 255, 9032. https://doi.org/10.1016/j.apsusc.2009.06.087 (2009).

Z. Li, S. Zhao, R.O. Ritchie, and M.A. Meyers, Prog. Mater. Sci 102, 296. https://doi.org/10.1016/j.pmatsci.2018.12.003 (2019).

H. Diao, X. Xie, F. Sun, K.A. Dahmen and P.K. Liaw, HEA 181–236 (2016). doi:https://doi.org/10.1007/978-3-319-27013-5_6

G.-H. Meng, B.-Y. Zhang, H. Liu, G.-J. Yang, T. Xu, C.-X. Li, and C.-J. Li, Surf. Coat. Technol. 347, 54. https://doi.org/10.1016/j.surfcoat.2018.04.068 (2018).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Prog. Mater. Sci 61, 1. https://doi.org/10.1016/j.pmatsci.2013.10.001 (2014).

X.-W. Qiu, Y.-P. Zhang, L. He, and C.-G. Liu, J. Alloys Compd. 549, 195. https://doi.org/10.1016/j.jallcom.2012.09.091 (2013).

Z. Cui, Z. Qin, P. Dong, Y. Mi, D. Gong, and W. Li, Mater. Lett. 259, 126769. https://doi.org/10.1016/j.matlet.2019.126769 (2020).

A. Erdogan, and K.M. Doleker, Trans Nonferr Metal Soc 31, 2428. https://doi.org/10.1016/S1003-6326(21)65664-9 (2021).

M. Кandeva, E. Zadorozhnaya, Z. Kalitchin, and P. Svoboda, J. Balk. Tribol. Assoc. 24, 411. (2018).

T. Sidhu, S. Prakash, and R. Agrawal, Acta Mater. 54, 773. https://doi.org/10.1016/j.actamat.2005.10.009 (2006).

M. Srivastava, M. Jadhav, R. Chakradhar, M. Muniprakash, and S. Singh, Surf. Coat. Technol. 378, 124950. https://doi.org/10.1016/j.surfcoat.2019.124950 (2019).

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, and S.L. Sing, Appl. Phys. Rev. 2, 041101. https://doi.org/10.1063/1.4935926 (2015).

J. Lapin, T. Pelachová, and M. Dománková, Intermetallics (Barking) 95, 24. https://doi.org/10.1016/j.intermet.2018.01.013 (2018).

Y.-J. Xie, and M.-C. Wang, Surf. Coat. Technol. 201, 3564. https://doi.org/10.1016/j.surfcoat.2006.08.107 (2006).

L. Pawlowski, The science and engineering of thermal spray coatings (Wiley, London, 2008).

W. Ruijun, Q. Yiyu, and L. Jun, Appl. Surf. Sci. 240, 42. https://doi.org/10.1016/j.apsusc.2004.05.299 (2005).

G. Kirik, O. Gaponova, V. Tarelnyk, O. Myslyvchenko, and B. Antoszewski, Powder Metall. Met. Ceram. 56, 688. https://doi.org/10.1007/s11106-018-9944-6 (2018).

C. Wu, S. Zhang, C. Zhang, J. Chen, and S. Dong, Opt Laser Technol. 94, 68. https://doi.org/10.1016/j.optlastec.2017.03.023 (2017).

G. Jin, Z. Cai, Y. Guan, X. Cui, Z. Liu, Y. Li, and M. Dong, Appl. Surf. Sci. 445, 113. https://doi.org/10.1016/j.apsusc.2018.03.135 (2018).

B. Gill, and R. Tucker, Mater. Sci. 2, 207. https://doi.org/10.1179/mst.1986.2.3.207 (1986).

P. Fauchais, M. Vardelle, A. Vardelle, and L. Bianchi, Ceram. Int. 22, 295. https://doi.org/10.1016/0272-8842(95)00106-9 (1996).

M. Löbel, T. Lindner, C. Kohrt and T. Lampke, In IOP Conference Series: Mater. Sci. Eng. (IOP Publishing: 2017), p. 012015. https://doi.org/10.1088/1757-899X/181/1/012015

J.-K. Xiao, H. Tan, Y.-Q. Wu, J. Chen, and C. Zhang, Surf. Coat. Technol. 385, 125430. https://doi.org/10.1016/j.surfcoat.2020.125430 (2020).

N. Tan, Z.-G. Xing, X.-L. Wang, H.-D. Wang, G. Jin, and B.-S.J. Xu, J. Mater. Res. 32, 1682. https://doi.org/10.1557/jmr.2017.164 (2017).

C. Chen, N. Liu, J. Zhang, J. Cao, L. Wang, and H. Xiang, J Mater Sci Technol. 35, 1883. https://doi.org/10.1080/02670836.2019.1652785 (2019).

N.K. Adomako, J.H. Kim, and Y.T. Hyun, J. Therm. Anal. Calorim. 133, 13. https://doi.org/10.1007/s10973-018-6963-y (2018).

K. Mehmood, M.A. Umer, A.U. Munawar, M. Imran, M. Shahid, M. Ilyas, R. Firdous, H. Kousar, and M. Usman, Materials 15, 1486. https://doi.org/10.3390/ma15041486 (2022).

A.S. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, P.S.R.S. Kottada and B. Murty, Comparison of Plasma Sprayed High Entropy Alloys with Conventional Bond Coat Materials. Paper presented at International Thermal Spray Conference, Long Beach, California, USA, 11–14 May 2015. https://doi.org/10.31399/asm.cp.itsc2015p0027

M. Kumar, M. Das, J.D. Majumdar, and I. Manna, Surf. Coat. Technol. 402, 126345. https://doi.org/10.1016/j.surfcoat.2020.126345 (2020).

K.M. Döleker, A. Erdogan, T. Yener, A.C. Karaoglanlı, O. Uzun, M.S. Gök, and S. Zeytin, Surf. Coat. Technol. 412, 127069. https://doi.org/10.1016/j.surfcoat.2021.127069 (2021).

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, S. Praveen, R.S. Kottada, and B. Murty, Metall Mater Trans A Phys Metall Mater Sci. 46, 791. https://doi.org/10.1007/s11661-014-2644-z (2015).

A. Meghwal, A. Anupam, V. Luzin, C. Schulz, C. Hall, B. Murty, R.S. Kottada, C.C. Berndt, and A.S.M.J. Ang, J. Alloys Compd. 854, 157140. https://doi.org/10.1016/j.jallcom.2020.157140 (2021).

S.W. Rukhande, and W.S. Rathod, Ceram. Int. 46, 18498. https://doi.org/10.1016/j.ceramint.2020.04.155 (2020).

T. Butler, J. Alfano, R. Martens, and M. Weaver, JOM 67, 246. https://doi.org/10.1007/s11837-014-1185-7 (2015).

M. Imran, Z. Saeed, M. Pervaiz, K. Mehmood, R. Ejaz, U. Younas, H.A. Nadeem, S. Hussain, and B. Spectroscopy, Spectrochim. Acta A Mol. Biomol. Spectrosc. 255, 119644. https://doi.org/10.1016/j.saa.2021.119644 (2021).

D.-Y. Lin, N.-N. Zhang, B. He, B.-Q. Jin, Y. Zhang, D.-Y. Li, and F.-Y. Dong, J. Iron Steel Res. Int. 24, 1199. https://doi.org/10.1016/S1006-706X(18)30018-9 (2017).

H. Grewal, H. Singh, and A. Agrawal, Surf. Coat. Technol. 216, 78. https://doi.org/10.1016/j.surfcoat.2012.11.029 (2013).

L. Baiamonte, C. Bartuli, F. Marra, A. Gisario, and G. Pulci, Coatings 9, 347. https://doi.org/10.3390/coatings9060347 (2019).

N. Arshad, M. Imran, M. Akram, and F. Altaf, Port. Electrochimica Acta 40(3), 193. https://doi.org/10.4152/pea.2022400304 (2022).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mehmood, K., Imran, M., Ali, L. et al. Development of Cost-Effective Microstructure and Isothermal Oxidation-Resistant Bond Coats on Inconel 718 by Atmospheric Plasma-Sprayed NiCoCrAlFe High-Entropy Alloy. JOM 75, 239–247 (2023). https://doi.org/10.1007/s11837-022-05578-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05578-5