Abstract

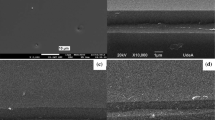

A chromium (Cr) coating was fabricated on 45 steel by electrodeposition with a trivalent–chromium (Cr3+) electrolyte. The morphologies and element distributions of the obtained coating were analyzed using a scanning electronic microscope, energy dispersive spectrometer, atomic force microscope, x-ray diffraction, and x-ray photoelectron spectroscopy. The effects of normal load and sliding speed on the tribological performance of the Cr coating were analyzed using a friction tester. The results show that the Cr coating with the roughness of 85.5 nm is composed of the Cr phase. The average coefficients of friction (COFs) of the Cr coating under the normal loads of 1 N, 3 N, and 5 N are decreased from 1.08 to 0.69, exhibiting excellent friction reduction; while its wear rates increase with the increase of the normal load, and the wear resistance becomes poor. Moreover, the average COFs of Cr coating at the sliding speeds of 600 times/min, 700 times/min, and 800 times/min are in the range of 0.71–0.76, and the wear rate is the lowest at the sliding speed of 700 times/min, showing that the friction reduction under the normal load of 3 N and wear resistance at the sliding speed of 700 times/min are the best.

Similar content being viewed by others

References

X.K. Li, R. Wang, Z. Xin, Y.J. Dong, J.H. Xu, and D.Q. Wei, Mater. Lett. 296, 129934 (2021).

T. Shinonag, A. Okada, H. Liu, and M. Kimura, J. Mater. Process. Technol. 254, 229 (2018).

W.C. Kong, Z. Yu, and J. Hu, Corros. Sci. 204, 110375 (2022).

A.H. Ching, K.L. Che, and H.Y. Yu, Surf. Coat. Tech. 205(1), 139 (2010).

F. Mukhtar, F. Qayyum, Z. Anjum, and M. Shah, Wear 418–419, 215 (2019).

J.M. Prabhakar, R.S. Varanasi, C.C. Silva, Saba, A. Vooys, A. Erbe, and M. Rohwerder, Corros. Sci. 187, 109525 (2021).

L. Büker, R. Böttcher, M. Leimbach, T. Hahne, R. Dickbreder, and A. Bund, Electrochim. Acta 411, 140054 (2022).

G. Bikulčius, A. Češunienė, A. Selskienė, V. Pakštas, and T. Matijošius, Surf. Coat. Technol. 315, 130 (2017).

F.I. Danilov, V.S. Protsenko, V.O. Gordiienko, and S.C. Kwon, Appl. Surf. Sci. 257(18), 8048 (2011).

N. Wint, D.J. Warren, A.C.A. DeVooys, and H.N. McMurray, J. Electrochem. Soc. 167, 141506 (2020).

A.M. Liang, L.W. Ni, Q. Liu, and J.Y. Zhang, Surf. Coat. Technol. 218, 23 (2013).

G. Saravanan and S. Mohan, J. Appl. Electrochem. 40, 1 (2010).

Z. Zeng, L. Wang, A. Liang, and J. Zhang, Electrochim. Acta 52, 1366 (2006).

S.K. Ibrahim, D.T. Gawne, and A. Watson, Trans. Inst. Met. Finish. 76, 156 (1998).

C.W. Liao, H.B. Lee, K.H. Hou, S.Y. Jian, C.E. Lu, and M.D. Ger, Electrochim. Acta. 209, 244 (2016).

S. Mahdavi and S.R. Allahkaram, J. Alloys Compd. 635, 150 (2015).

M. Gsellmann, D. Scheiber, T. Klünsner, J. Zálešák, Z.L. Zhang, H. Leitner, C. Mitterer, G. Ressel, and L. Romaner, Acta Mater. 222, 117439 (2022).

W.X. Zhu and D.J. Kong, Mater. Sci. Pol. 39(3), 395 (2021).

J.L. Zhou and D.J. Kong, J. Mater. Eng. Perform. 29, 7428 (2020).

C.E. Lu, N.W. Pu, K.H. Hou, C.C. Tseng, and M.D. Ger, Appl. Sur. Sci. 282, 544 (2013).

X.Y. Fu, T. Sotani, and H. Matsuyama, Desalination 233, 10 (2008).

W.C. Kong, Z. Yu, and J. Hu, Ceram. Int. 47, 34425 (2021).

J.L. Zhou and D.J. Kong, Surf. Coat. Technol. 408, 126816 (2021).

J.L. Zhou and D.J. Kong, Surf. Coat. Technol. 383, 125229 (2020).

Y. Wang, Y.H. Liu, G.B. Li, M.M. Zheng, Y.S. Li, A.L. Zhang, and Y.C. Zhang, Surf. Coat. Technol. 422, 127527 (2021).

W.M. Su, S.P. Niu, Y.C. Huang, C. Wang, Y.Y. Wen, X. Li, C.M. Deng, C.G. Deng, and M. Liu, Ceram. Int. 48(6), 8696 (2022).

T.T. Zhang, H. Lan, C.B. Huang, L.Z. Du, and W.G. Zhang, Surf. Coat. Technol. 319, 47 (2017).

F. Cai, J.M. Zhang, J.M. Wang, J. Zheng, Q.M. Wang, and S.H. Zhang, Tribol. Int. 153, 106657 (2021).

X.D. Sui, J.Y. Liu, S.T. Zhang, J. Yang, and J.Y. Hao, Appl. Surf. Sci. 439, 24 (2018).

B.S. Zhang, Y.Q. Yu, S.S. Zhu, Z.J. Zhang, X.W. Tao, Z.Z. Wang, and B. Lu, Mater. Chem. Phys. 276, 125352 (2022).

J.L. Daure, M.J. Carrington, P.H. Shipway, D.G. McCartney, and D.A. Stewart, Surf. Coat. Technol. 350, 40 (2018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, W., Xu, Y. & Kong, D. Microstructure and Tribological Performance of Electrodeposited Cr Coating with Trivalent–Chromium Electrolyte. JOM 74, 4575–4582 (2022). https://doi.org/10.1007/s11837-022-05577-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05577-6