Abstract

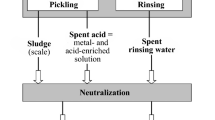

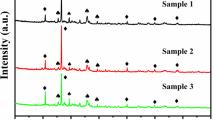

The resource utilization and stabilization disposal of stainless steel pickling sludge has received more and more attention from domestic and foreign scholars. Here, a sustainable treatment process of low-silica reduction smelting for stainless steel pickling sludge, followed by low-temperature vitrification for the reduced slag, has been proposed. The metal yield can reach more than 98% and metal content in the slag is lower than 0.6% under the optimal conditions of 1400 C temperature, 15% coal ratio, 10% SiO2 addition, and 1.5 h reaction time. The distinguishable crystal phase in the alloy mainly contained FeNi intermetallic compounds. The reduced slag mainly consisted of fluorite, anorthite, and magnesium silicate. The vitrification experiments implied that it was conducive to increase the vitreous body content of reduced slag via lowering the temperature. The vitreous body content of vitrification products can reach more than 85% when the SiO2 addition is in the range of 10–20% at 1250°C. This work puts forward a new perspective to achieve both the recovery of valuable metals and the reduction of the slag amount.

Similar content being viewed by others

References

M. Rabi, K.A. Cashell and R. Shamass, Eng. Struct. 198, 109432.1. (2019)

N.A. Ayşe, K.E. Abdul, and A. Ekicibil, J. Mol. Struct. 1198, 126876. (2019)

B. Zheng, G. Shu, and Q. Jiang, J. Constr. Steel Res. 160, 110. (2019)

B.I. Musah, L. Peng, and Y.F. Xu, IOP Conf. Ser. Earth Environ. Sci. 728, 012011. (2021)

C.C. Yang, J. Pan, D.Q. Zhu, Z.Q. Guo, and X.M. Li, J. Iron Steel Res. Int. 26, 547. (2019)

S. Zhao, B. Liu, Y. Ding, J. Zhang, Q. Wen, and C. Ekberg, S. Zhang. J. Cleaner Prod. 271, 122674. (2020)

S. Liu, Q. Li, Z. Wang, F. Yang, and X. Lu, J. Cleaner Prod. 247, 119580. (2020)

J.L. Fang and W.T. Yang, China Resour. Comprehen. Util. 32, 24. (2014)

J.X. Zhao, Z.Y. Zhao, and R.M. Shi, JOM 70, 2825. (2018)

G. Ma and A.M. Garbers-Craig, Ironmaking Steelmaking 33, 229. (2006)

C.J. Liu, Y.Y. Yue, and P.Y. Shi, China Metall. 26, 39. (2016)

I. Masahiko, T. Rinso, and F. Katsuji, J. Chem. Eng. Jpn. 31, 589. (1998)

Ministry of Ecology and Environment of the People’s Republic of China, National Hazardous Waste Directory, 2016–06–21, Reference No. 000014672/2016–00562

P.Y. Liu, D.S. Tan, and W.Z. Ding, Nonferrous Mater. Eng. 38, 149. (2017)

R.A. Pepper, S.J. Couperthwaite, and G.J. Millar, Miner. Eng. 99, 8. (2016)

H.N. Gu, T.F. Guo, and S.C. Ma, Chem. Ind. Eng. Prog. 37, 3599. (2018)

T.H. Shi and K. Chen, Pollut. Control Technol. 20, 48. (2007)

R.J. Su, B. Liang, and J. Guan, Procedia. Environ. Sci. 31, 361. (2016)

Y. Liu, Iron & Steel Scrap of China 1, 23. (2007)

J. Zhang, Y. Sun, and X.L. Liu, Chin. J. Process. Eng. 14, 782. (2014)

K. Xu, Shanghai: Tongji University, 2006

X. Wu, Changsha: Hunan Agricultural University, 2010

X.M. Li, E. Mousa, and J.X. Zhao, J. Iron Steel Res. Int. 16, 480. (2009)

J.X. Zhao, X.M. Li, and Y. Zeng, J. Chin. Soc. Rare Earths 28, 697. (2010)

N. Yoshikawa, K. Mashiko, and Y. Sasaki, ISIJ Int. 48, 690. (2008)

P. Ma, B. Lindblom, and B. Bjorkman, Scand. J. Metall. 34, 31. (2005)

J. Shu, T. Lei, Y. Deng, M. Chen, X. Zeng, and R. Liu, RSC Adv. 11, 6877. (2021)

H.G. Li, Metallurgy Principle (Science Press, Beijing, 2005), pp 78–84

F.A. Lopez, E. Sáinz, and A. López-Delgado, Metall. Mater. Trans. B 27, 379. (1996)

C.W. Bale, P. Chartrand, and S.A. Degterov, Calphad 33, 295. (2009)

C.W. Bale, E. Bélisle, and P. Chartrand, Calphad 54, 35. (2016)

C.A. Pickles, J. Hazard. Mater. 150, 265. (2008)

B. Ma, X.F. Yan, and Z.H. Zhao, Res. Environ. Sci. 34, 1006. (2021)

Acknowledgements

This study is supported by the National Natural Science Foundation of China (52004111, 51864019), the Program of Qingjiang Excellent Young Talents, Jiangxi University of Science and Technology, and the “Double Thousand Plan” talent project of Jiangxi Province (jxsq2018106051).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, Y., Yang, Y., Huang, Y. et al. A Sustainable Process for the Resource Utilization and Stabilization Disposal of Stainless Steel Pickling Sludge. JOM 74, 3910–3920 (2022). https://doi.org/10.1007/s11837-022-05422-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05422-w