Abstract

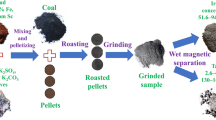

We have investigated Bayer red mud with a TFe content of 26.86% collected from the Pingguo area of China, and have found that iron is the key metal affecting the extraction of valuable components such as Sc, Ti, and Ga. Based on this, an efficient process of roasting with calcium salt and magnetic separation has been proposed to extract iron from the Bayer red mud. Coke, calcium chloride, and calcium hypochlorite were put into a resistance furnace for roasting, and iron was converted from low-intensity magnetic iron minerals to high-intensity magnetic iron minerals. Iron was recovered from the roasted ore by low-intensity magnetic separation after wet grinding. We found that calcium chloride and calcium hypochlorite can promote FeO to be reduced to Fe0 on the coke surface after FeCl3 is added, and that CaO produced by calcite decomposition can promote FeSiO3 to be reduced to Fe0, which significantly increases the content of metal iron in the roasted ore. An iron concentrate with a TFe content of 86.86% and an iron recovery of 91.48% was obtained. The main minerals in the iron concentrate were Fe0 and Fe3O4, which accounted for 58.78% and 20.37% of the total iron, respectively.

Similar content being viewed by others

References

R. Khanna, Y. Konyukhov, D. Zinoveev, K. Jayasankar, I. Burmistrov, M. Kravchenko, and P.S. Mukherjee, Sustainability 14, 1258 https://doi.org/10.3390/su14031258 (2022).

A.B. Botelho, D.C.R. Espinosa, J. Vaughan, and J.A.S. Tenorio, Miner. Eng. 172, 107148 https://doi.org/10.1016/j.mineng.2021.107148 (2021).

S. Agrawal, and N. Dhawan, Miner Eng. 171, 107084 https://doi.org/10.1016/j.mineng.2021.107084 (2021).

H.X. Zhao, F.S. Zhou, L.M.A. Evelina, J.L. Liu, and Y. Zhou, J. Hazard. Mater. 423, 127056 https://doi.org/10.1016/j.jhazmat.2021.127056 (2022).

S. Eray, E. Keskinkilic, Y.A. Topkaya, and A. Geveci, JOM 74, 456 https://doi.org/10.1007/s11837-021-05076-0 (2022).

W. Ding, J.H. Xiao, Y. Peng, S.Y. Shen, T. Chen, K. Zou, and Z. Wang, Miner. Process. Extr. Metall. Rev. 43, 61 https://doi.org/10.1080/08827508.2020.1833195 (2022).

A.M. Ahamed, M.N. Pons, Q. Ricoux, F. Goettmann, and F. Lapicque, J. Environ. Manage. 266, 110547 https://doi.org/10.1016/j.jenvman.2020.110547 (2020).

M. Archambo and S.K. Kawatra, Miner. Process. Extr. Metall. Rev. 42, 427 https://doi.org/10.1080/08827508.2020.1781109 (2021).

H. Habibi, D. Pirouzan, S. Shakibania, Z. Pourkarimi, and M. Mokmeli, Environ. (Pollut. Res, Sci, 2022) https://doi.org/10.1007/s11356-022-20244-8.

H.N. Gu, N. Wang, and J.S.J. Hargreaves, J. Sustain. Metall. 4, 147 https://doi.org/10.1007/s40831-018-0164-6 (2018).

P. Wang and D.Y. Liu, Materials 10, 1800 https://doi.org/10.3390/ma5101800 (2012).

W. Ding, S.X. Bao, Y.M. Zhang, and J.H. Xiao, Miner (Extr. Metall. Rev, Process, 2022) https://doi.org/10.1080/08827508.2022.2047044.

J.H. Xiao, K. Zou, T. Chen, W.L. Xiong, and B. Deng, Metals 11, 563 https://doi.org/10.3390/met11040563 (2021).

J.H. Xiao, W. Ding, Y. Peng, T. Chen, K. Zou, and Z. Wang, Minerals 10, 352 https://doi.org/10.3390/min10040352 (2020).

W. Ding, J.H. Xiao, Y. Peng, S.Y. Shen, and T. Chen, Miner. Process. Extr. Metall. Rev. 42, 153 https://doi.org/10.1080/08827508.2019.1706049 (2020).

S.H. Wang, H.X. Jin, Y. Deng, and Y.D. Xiao, J. Cleaner Prod. 289, 125136 https://doi.org/10.1016/j.jclepro.2020.125136 (2021).

G.Y. Hu, H.H. Tang, D.D. He, W. Sun, and L. Wang, Miner. Eng. 173, 107180 https://doi.org/10.1016/j.mineng.2021.107180 (2021).

X. Liu, P. Gao, S. Yuan, Y. Lv, and Y.X. Han, Miner. Eng. 157, 106553 https://doi.org/10.1016/j.mineng.2020.106553 (2020).

B. Swain, A. Akcil, and J.C. Lee, Crit. Rev. Environ. Sci. Technol. 52, 520 https://doi.org/10.1080/10643389.2020.1829898 (2020).

J.H. Xiao, K. Zou, T. Chen, Y. Peng, W. Ding, J.H. Chen, B. Deng, H. Li, and Z. Wang, JOM 73, 1836 https://doi.org/10.1007/s11837-021-04665-3 (2021).

A.D. Salman, T. Juzsakova, A. Rdey, P.C. Le, X.C. Nguyen, E. Domokos, T.A. Abdullah, V. Vagvolgyi, S.W. Chang, and D.D. Nguyen, Chem. Eng. Technol. 44, 1768 https://doi.org/10.1002/ceat.202100223 (2021).

J.H. Xiao, W. Ding, Y. Peng, Q. Wu, Z.Q. Chen, Z. Wang, J.M. Wang, and T.F. Peng, J. Min. Metall. Sect. B. 55, 305 https://doi.org/10.2298/JMMB180722032X (2019).

S. Li, Z.S. Kang, W.C. Liu, Y.C. Lian, and H.S. Yang, J. Sustain. Metall. 7, 126 https://doi.org/10.1007/s40831-020-00326-y (2021).

C.H. Borgert, L.R. Neto, F.F. Grillo, J.R. de Oliveira, J.L. Coleti, J.A.S. Tenorio, D.C.R. Espinosa, T.E.A. Frizon, M.V.G. Zimmermann, and E. Junca, JOM 74, 439 https://doi.org/10.1007/s11837-021-05075-1 (2022).

J. Bud, Y. Mochizuki, and N. Tsubouchi, ISIJ Int. 62, 20. https://doi.org/10.2355/isijinternational.ISIJINT-2021-295 (2022).

J.C. Dong, Y.G. Wei, S.W. Zhou, B. Li, Y.D. Yang, and A. Mclean, JOM 10, 2365 https://doi.org/10.1007/s11837-018-3032-8 (2018).

P. Grudinsky, D. Zinoveev, A. Yurtaeva, A. Kondratiev, V. Dyubanov, and A. Petelin, J. Sustain. Metall. 67, 858 https://doi.org/10.1007/s40831-021-00400-z (2021).

J.N. Pei, X.L. Pan, Y.M. Zhang, H.Y. Yu, and G.F. Tu, J. Environ. Chem. Eng. 9, 106754 https://doi.org/10.1016/j.jece.2021.106754 (2021).

W.W. Wang and Z.Y. Li, Miner. Eng. 155, 106453 https://doi.org/10.1016/j.mineng.2020.106453 (2020).

J.H. Xiao, W.L. Xiong, K. Zou, T. Chen, H. Li, and Z. Wang, J. Sustain. Metall. 7, 642 https://doi.org/10.1007/s40831-021-00364-0 (2021).

S. Yuan, W.T. Zhou, Y.J. Li, and Y.X. Han, Trans. Nonferrous Met. Soc. China. 30, 812 https://doi.org/10.1016/S1003-6326(20)65256-6 (2020).

S.W. Li, J. Pan, D.Q. Zhu, Z.Q. Guo, Y. Shi, T. Dong, S.H. Lu, and H.Y. Tian, Resour. Conserv. Recycl. 168, 105314 https://doi.org/10.1016/j.resconrec.2020.105314 (2021).

A.P. He, J.M. Zeng, and S.H. Liu, J. Iron Steel Res. Int. 28(6), 661–668 https://doi.org/10.1007/s42243-020-00555-1 (2021).

S. Shoppert, I. Loginova, J. Napol’skikh, A. Kyrchikov, L. Chaikin, D. Rogozhnikov, and D. Valeev, Materials 15, 433 https://doi.org/10.3390/ma15020433 (2022).

P. Kannan, F. Banat, S.W. Hasan, and M. Abu Haija, Hydrometallurgy 206, 105758 https://doi.org/10.1016/j.hydromet.2021.105758 (2021).

Acknowledgements

This study was funded by the Sichuan Science and Technology Program (Grant Nos. 2022YFS0462, 2021YJ0057, and 2021YFG0268), the Project funded by China Postdoctoral Science Foundation (Grant No. 2014M560734), and Key Laboratory of Guangdong Provincial Key Laboratory of Radioactive and Rare Resource Utilization (Grant No. 2018B030322009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could influence the work reported in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xiao, J., Zhong, N., Gao, D. et al. An Efficient Process to Recover Iron from Bayer Red Mud. JOM 74, 3172–3180 (2022). https://doi.org/10.1007/s11837-022-05373-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05373-2