Abstract

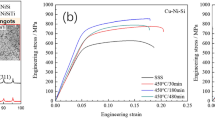

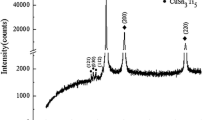

A high strength and super electrical conductive Cu–3Ti–1.5Ni–0.5Si quaternary alloy with improved hardness and ductility has been developed. The alloy components were melted in an inert gas controlled vacuum melting furnace, rapidly cooled in ice, homogenized at 900°C for 5 h, and age heat treated at an aging temperature of 480°C for 1, 2, 3, 4, and 5 h, respectively. The strength, hardness, ductility, and the electrical conductivity of the developed alloys were investigated and the microstructure analyzed using scanning electron microscopy (SEM). The average grain size and particle size distributions were obtained and discussed. Results show that the alloy recorded high strength and hardness of 760 MPa and 385 HV, respectively, after aging for 5 h. These improvements were linked with the minimal average grain size of ~4.5 µm and uniform particle size distribution. Excellent electrical conductivity and percentage elongation with maximum values of 37.4% IACS and 25.1%, respectively, were also recorded after 1 h. The studied Cu–3Ti–1.5Ti–0.5Si alloy demonstrated excellent combinations of ductility, strength, hardness, and electrical conductivity.

Similar content being viewed by others

References

K.C. Nnakwo, C.N. Mbah, and E.E. Nnuka, Heliyon. https://doi.org/10.1016/j.heliyon.2019.e02471 (2019).

K.C. Nnakwo, C.N. Mbah, and S.N. Ude, J. King Saud Univ. Eng. Sci. 32(5), 287. (2020).

K.C. Nnakwo, C.N. Mbah, and C.C. Daniel-Mkpume, J. King Saud Univ. Sci. 31(4), 1056. (2019).

K.C. Nnakwo, J. King Saud Univ. Sci. https://doi.org/10.1016/j.jksus.2017.12.002 (2019).

M. Masamichi, and O. Yoshikiyo, Mater. Trans. JIM. 29(11), 903. (1988).

X. Guoliang, W. Qiangsong, M. Xujun, X. Baiqing, and P. Lijun, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2012.08.007 (2012).

S. Semboshi, Y. Kaneno, T. Takasugi, S.Z. Han, and N. Masahashi, Metall. Mater. Trans. A 50, 1389. (2019).

S. Semboshi, Y. Kaneno, T. Takasugi, and N. Masahashi, Metall. Mater. Trans. A 49, 4956. (2018).

S. Semboshi, S. Sato, M. Ishikuro, K. Wagatsuma, A. Iwase, and T. Takasugi, Metall. Mater. Trans. A 45, 3401. (2014).

W.A. Soffa, and D.E. Laughlin, Redivivus. Prog. Mater. Sci. 49, 347. (2004).

J. Liu, X. Wang, Q. Ran, G. Zhao, and X. Zhu, Trans. Non. Metall. Soc. China 26(12), 3183. (2016).

D. Božić, O. Dimčić, B. Dimčić, I. Cvijović, and V. Rajkovi, Mater. Charact. 59, 1122. (2008).

X. Wang, Z. Xiao, W. Qiu, Z. Li, and F. Liu, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2020.140510 (2021).

S. Nagarjuna, K. Balasubramanian, and D.S. Sarma, J. Mater. Sci. 34(12), 2929. (1999).

R. Markandeya, S. Nagarjuna, and D.S. Sarma, Mater. Sci. Eng. A 371(1–2), 291. (2004).

K.C. Nnakwo, F.O. Osakwe, B.C. Ugwuanyi, P.A. Oghenekowho, I.U. Okeke, and E.A. Maduka, SN Appl. Sci. 3(11), 829. (2021).

J. Liu, J. Liu, X. Wang, C. Fu, Y. Wang, L. Lu, and J. Zheng, Mater. Technol. 55(4), 483. (2021).

S. Suzuki, N. Shibutani, K. Mimura, M. Isshiki, and Y. Waseda, J. Alloy Compd. 417(1–2), 116. (2006).

L. Jia, H. Xie, Z.L. Lu, X. Wang, and S.M. Wang, Mater. Sci. Technol. 28(2), 243. (2012).

Z. Li, Z.Y. Pan, Y.Y. Zhao, Z. Xiao, and M.P. Wang, J. Mater. Res. 24(6), 2123. (2009).

F. Huang, M. Jusheng, N. Honglong, C. YuWen, and G. Zhiting, Mater. Lett. 57, 2135. (2003).

S. Puathawee, S. Rojananan, and S. Rojananan, Adv. Mater. Res. 802, 169. (2013).

N. Xiong, R. Bao, J. Yi, D. Fang, J. Tao, and Y. Liu, J. Alloys Compd. 770, 204. (2019).

S. Nagarjuna, K. Balasubramanian, and D.S. Sarma, J. Mater. Sci. 32(13), 3375. (1997).

R. Knights, and P. Wilkes, Acta Metall. Mater. 21, 1503. (1973).

S. Ramesh, H.N. Shivananda, K.R. Gopi, and S.S. Sahu, Mater. Res. Exp. https://doi.org/10.1088/2053-1591/aaf085 (2019).

P. Zhang, Y. Li, Q. Lei, H. Tan, R. Shi, J. She, and Z. Li, J. Mater. Res. Technol. 9(2), 2299. (2020).

Y.H. Yang, S.Y. Li, Z.S. Cui, Z. Li, Y.P. Li, and Q. Li, Rare Met. https://doi.org/10.1007/s12598-020-01699-5 (2021).

Acknowledgement

The authors appreciate the support of Notex Electronics Nig. Ltd, Cutix Cable Plc., and Unique Foundry towards the successful completion of this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nnakwo, K.C., Odo, J.U., Eweka, K.O. et al. Evaluation of the Electrical Conductivity and Mechanical Properties of Cu–3Ti–1.5Ni–0.5Si Quaternary Alloy. JOM 74, 4174–4180 (2022). https://doi.org/10.1007/s11837-022-05293-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05293-1