Abstract

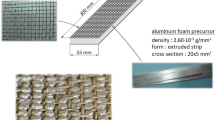

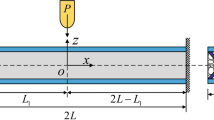

This paper reports a study of steel foams, one with a single layer of spherical cells and another with two layers of cells, under compressive and flexural loading. The steel foam specimens were cut from large-size foam plates made by casting AISI 8630 steel into molds filled with spherical sand cores. A 2D unit cell model was proposed based on stress fields in solid media with circular cuts, and finite element analyses were conducted to explain the observed behavior. The results indicated that higher initial stiffness and increased flexural strength in steel foam specimens can be achieved compared to solid steel specimens. The tests also revealed that the behavior of these foam plates in bending may be reduced by fracture resulting from stress concentration of perforated faces in tension. It is thus recommended that the perforated faces should be placed in compression zones to take advantages of metal foams.

Similar content being viewed by others

References

I. Seilie, and J. Hooper, Mod. Steel Constr. 45(4), 37 (2005)

B. Smith, S. Szyniszewski, J. Hajjar, B. Schafer, and S. Arwade, J. Constr. Steel Res. 71, 1 (2012)

L. Gibson, and M. Ashby, Cellular solids: Structure & properties (Cambridge University Press, Cambridge, 1997)

M. Ashby, T. Evans, N. Fleck, J. Hutchinson, H. Wadley, and L. Gibson, Metal foams: A design guide (Elsevier, Amsterdam, 2000)

J. Banhart, Scienxt J. Mech. Eng. 3(1), 279 (2007)

B. Oliveira, L. Cunda, A. Öchsner, and G. Creus, Mater. Werkst. 39, 133 (2008)

F. García-Moreno, Materials 9(2), 85 https://doi.org/10.3390/ma9020085 (2016)

J. Banhart, Prog. Mater. Sci. 46(6), 559 https://doi.org/10.1016/S0079-6425(00)00002-5 (2001)

H. Roshan, U.S. Patent 9623480B2, (2017)

H. Roshan, AFS Proc. 121st Metal Casting Congress, Milwaukee, WI (2019a)

H. Roshan, Metal. Cast. Des. Purch. 38 (2019b)

F. Grote, and P. Busse, Mater. Werkst. 31(6), 415 (in German) (2000)

H.I. Bakan, Scr. Mater. 55(2), 203 (2006)

C. Park, and S.R. Nutt, Mater. Sci. Eng. A 288(1), 111 (2000)

G. Castro, and S.R. Nutt, Mater. Sci. Eng. A 553, 89 (2012)

L. Peroni, M. Scapin, C. Fichera, D. Lehmbus, J. Weise, J. Baumeister, and M. Avall, Compos. Parts B 66, 430 (2014)

B. Nuray, and O. Enver, Mater. Des. 53, 482 (2014)

D. Mondal, H. Jain, S. Das, and A. Jha, Mater. Des. 88, 430. (2015).

T. Lim, B. Smith, and D. McDowell, Acta Mater. 50(11), 2867 (2002)

S. Szyniszewski, B. Smith, J. Hajjar, B. Schafer, and S. Arwade, Mater. Des. 54, 1083 (2014)

S. Szyniszewski, B. Smith, J. Hajjar, S. Arwade, and B. Schafer, Thin-Walled Struct. 59, 11 (2012)

AZO Materials (2012) AISI 8630 Alloy Steel (UNS G86300), Retrieved from http: https://www.azom.com/article.aspx?ArticleID=6689

G. Menges, and F. Knipschild, Polym. Eng. Sci. 15(8), 623 (1975)

Y. Murakami, Theory of elasticity and stress concentration (Wiley, Hoboken, 2016)

M. Greenspan, J. Res. Natl. Bur. Stand. (U.S.). 31, 305 (1943)

Acknowledgements

The authors would like to thank the following UWM undergraduate students who contributed to the experimental tests: Goyko Rajak and Ajay Kumar from the department of material science and engineering.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, J., Kordijazi, A., Valensa, C. et al. Behavior of Steel Foam Sandwich Members Cast with 3D Printed Sand Cores. JOM 74, 2083–2093 (2022). https://doi.org/10.1007/s11837-022-05157-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05157-8