Abstract

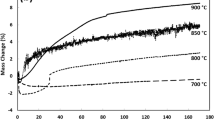

Gaseous reduction by hydrogen was proposed to decrease carbon dioxide emissions during the recovery of zinc and copper from brass waste. The reduction behavior and kinetics of brass waste were studied at temperatures between 1073 K (800°C) and 1273 K (1000°C) under an Ar-H2 atmosphere. Temporal phase and morphology changes were observed that explained the mechanism of brass waste reduction. Effects of hydrogen partial pressure and temperature on the reduction kinetics were investigated. The reduction rate increased with increase in hydrogen partial pressure and reduction temperature. The reduction kinetics of the brass waste were analyzed using various kinetic model equations for solid-gas reactions. In the first stage, oxygen was released from zinc and copper oxides at the particle boundary of the brass waste, and the reaction was chemically controlled at the interface. Subsequently, metallic zinc was vaporized at random nuclei sites, and the reaction was controlled by the power law. The calculated activation energies were 114.9 kJ/mol and 120.0 kJ/mol, respectively.

Similar content being viewed by others

References

Ö. Kahvecioglu, B. Derin, and O. Yücel, Miner. Process. Extr. Metall. 112, 95 (2003).

N. Mizuno, S. Kosai, and E. Yamasue, Jom 73, 1828 (2021).

H. Liu, Y. Zou, L. Tao, Z. Ma, D. Liu, P. Zhou, H. Liu, and S. Wang, Small 13, 1700758 (2017).

F. Ahmed, and N.C. Kar, IEEE Trans. Ind. Appl. 53, 3098 (2017).

H.U. Sverdrup, A.H. Olafsdottir, and K.V. Ragnarsdottir, Resour. Conserv. Recycl. 4, 100007 (2019).

A. Kilicarslan, and M.N. Saridede, Sep. Sci. Technol. 50, 286 (2015).

I.M. Ahmed, A.A. Nayl, and J.A. Daoud, J. Saudi Chem. Soc. 20, S280 (2016).

J.M.A. Martins, A.S. Guimarães, A.J.B. Dutra, and M.B. Mansur, J. Mater. Res. Technol. 9, 2319 (2020).

S.M. Abdel Basir, and M.A. Rabah, Hydrometallurgy 53, 31 (1999).

J. Trpcevska, E. Rudnik, B. Holkova, and M. Laubertova, Polish J. Environ. Stud. 27, 1 (2018).

Z. Xia, X. Zhang, X. Huang, S. Yang, Y. Chen, and L. Ye, Hydrometallurgy 197, 105475 (2020).

T.H. Lee, S.H. Joo, H.H. Nersisyan, M.S. Kong, J.W. Lee, K.W. Park, and J.H. Lee, KONA Powder Part. J. 33, 278 (2016).

L.F. Tong, Miner. Process. Extr. Metall. Rev. 23, 11 (2002).

H.K. Chen, Scand. J. Metall. 30, 292 (2001).

D. Spreitzer, and J. Schenk, Metall. Mater. Trans. B 50, 2471 (2019).

X. Peng, J. Wang, C. Li, H. Zuo, G. Wang, X. She, and Q. Xue, Jom 73, 2929 (2021).

B. Liu, Y. Zhang, Z. Su, Z. Peng, G. Li, and T. Jiang, Jom 69, 1669 (2017).

W. Lv, X. Lv, J. Xiang, K. Hu, S. Zhao, J. Dang, K. Han, and B. Song, Int. J. Hydrogen Energy 44, 4031 (2019).

Z. Wang, J. Zhang, K. Jiao, Z. Liu, and M. Barati, J. Alloys Compd. 729, 874 (2017).

L. Vlaev, N. Nedelchev, K. Gyurova, and M. Zagorcheva, J. Anal. Appl. Pyrolysis 81, 253 (2008).

C.E. Guger, and F.S. Manning, Metall. Mater. Trans. B 2, 3083 (1971).

S. Lew, A.F. Sarofim, and M. Flytzani-Stephanopoulos, Chem. Eng. Sci. 47, 1421 (1992).

J.-J. Lee, C.-I. Lin, and H.-K. Chen, Metall. Mater. Trans. B 32, 1033 (2001).

E. Junca, J.R. De Oliveira, T.A.G. Restivo, D.C.R. Espinosa, and J.A.S. Tenório, J. Therm. Anal. Calorim. 123, 631 (2016).

Acknowledgements

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korean government (MOTIE) (20217510100080, Development of Critical Metal Recovery Technologies (capacity of 200 kg/day) from low-grade solid wastes for the foundation of open access recycling platform).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choi, K., Park, H. Kinetics of Brass Waste by Hydrogen Reduction for Recovery of Valuable Metals. JOM 74, 878–884 (2022). https://doi.org/10.1007/s11837-021-05117-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-05117-8