Abstract

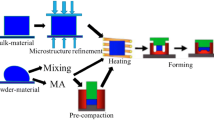

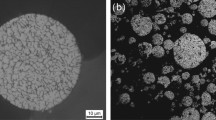

To control the microstructure and simulate the forming process of semisolid powder molding, the deformation micromechanisms and constitutive behaviors of powder materials were analyzed. Experiments including thermal simulation compression under the semisolid state and semisolid powder molding were carried out. The results show a rapid increase to the peak stress with elastic–plastic deformation occurring in stage I. In stage II, the powder material experiences rheological viscoplastic deformation under stable stress, and shear-induced contraction occurs. In stage III, an abrupt drop in stress and shear-induced dilation occurs, forming more defects. As the liquid fraction increases, the strain causing pore elimination and powder compaction decreases. The critical strain contraction-to-dilation transition decreases, which is completely opposite to that of dense materials. The modified constitutive equation of Mg-6Zn green compaction describes the semisolid compression behavior very well. Pseudo-transgranular liquation cracking (TLC) is the grain refinement mechanism, and the optimum compaction ratio is 20–30%.

Similar content being viewed by others

References

M.D. Pereda, C. Alonso, and L. Burgos-Asperilla, Acta Biomater. 6, 1772. (2010).

Y.F. Zheng, X.N. Gu, and Y.L. Xi, Acta Biomater. 6, 1783. (2010).

J.Y. Yu, J.Z. Wang, and Q. Li, Rare Metal Mater. Eng. 45, 2757. (2016).

M. Wolff, T. Mesterknecht, A. Bals, T. Ebel, and R. Willumeit-Römer, In: Joshi V., Jordon J., Orlov D., Neelameggham N. (eds) Magnesium Technology 2019. (Cham: Springer 2019). https://doi.org/10.1007/978-3-030-05789-3_8

J.G. Schaper. Magnesium Polyolefin Interactions during Thermal Debinding in the MIM Process of Magnesium. PhD thesis, Kiel University, 2019.

Y.C. Wang, P.H. Fu, N.Q. Wang, L.M. Peng, B. Kang, H. Zeng, G.Y. Yuan, and W.J. Ding, Engineering 6(11), 1267. (2020).

X. Luo, C. Fang, Z. Fan, B.S. Huang, and J. Yang, Mater. Res. Express 6(7), 076528. (2019).

X. Luo, S.H. Yang, M.Y. Li, Z.M. Tang, S.L. Wang, and B.S. Huang, Trans. Indian Inst. Met. https://doi.org/10.1007/s12666-021-02373-9 (2021).

Y.F. Wu: Fabrication of Metal Matrix Composite by Semi-Solid Powder Processing. PhD thesis,Iowa State University, Ames, 2011.

X. Luo, M. Wu, C. Fang, and B.S. Huang, JOM 71, 4349. (2019).

F. Czerwinski, Int. J. Cast Metals Res. 33, 157. https://doi.org/10.1080/13640461.2020.1801561 (2020).

F. Czerwinski, Mater. Sci. Technol. 35(9), 999. (2019).

F. Czerwinski, Metall. Mater. Trans. B 49(6), 3220. (2018).

Y. Xu, C. Chen, J.B. Jia, X.X. Zhang, H.H. Dai, and Y. Yang, J Alloys Compds 748, 694. (2018).

X. Luo, Y.Z. Liu, C.X. Gu, and Z.L. Li, Powder Technol. 216, 161. (2014).

M. Wu, Y.Z. Liu, T. Wang, and K.BYu. Mater, Sci. Eng. A 674, 144. (2016).

M.Z. Omar, H.V. Atkinson, and P. Kapranos, Metall. Mater. Trans. A 42(9), 2807. (2011).

R.M.K. Young, and T.W. Clyne, J. Mater. Sci. 21, 1057. (1986).

M. Wu. Process Principles and Numerical Simulation on Semi-solid Powder Forming and Porous Materials Deformation of 2024 Aluminum Alloy. Ph.D thesis, South China University of Technology, Guagnzhou, 2018 (in chinese)

W.C. Liu, L.X. Hu, J.Y. Shen, F. Gao, and Y. Sun, Mater. Sci. Eng. A 802, 140656. (2021).

K.M. Kareh, P.D. Lee, R.C. Atwood, T. Connolley, and C.M. Gourlay, Nat. Comm. 5, 1. https://doi.org/10.1038/ncomms5464 (2014).

T.C. Su, C. O’Sullivan, H. Yasuda, and C.M. Gourlay, Acta Mater. 191, 24. (2020).

E. Tzimas, and A. Zavaliangos, Acta Mater. 1(47), 517. (1999).

M. Kiuchi, R. Kopp, and C.I.R.P. Annals-Manuf, Technol. 51(2), 653. (2002).

W. Wang, E.Y. Guo, A.B. Phillion, D.G. Eskin, T.M. Wang, and P.D. Lee, Materialia 12, 100817. (2020).

A. Schofield, and C. Wroth, Critical State Soil Mechanics (McGraw-Hill, New York, 1968).

X. Luo, Y.Z. Liu, Z.Q. Mo, and C.X. Gu, Metall. Mater. Trans. A 46A, 2185. (2015).

S. Karagadde, P.D. Lee, B. Cai, J.L. Fife, M.A. Azeem, K.M. Kareh, C. Puncreobutr, D. Tsivoulas, T. Connolley, and R.C. Atwood, Nat. Comm. 6, 8300. https://doi.org/10.1038/ncomms9300 (2015).

Y.C. Lin, Q.F. Li, and Y.C. Xia, Mater. Sci. Eng. A 534(1), 654. (2012).

Acknowledgements

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (No. 51704255) and Sichuan Science and Technology Program (No. 2020YFH0151).

Author information

Authors and Affiliations

Contributions

Xia Luo, Mingyu Li, Jun Ren, and Min Wu contributed to the methodology, formal analysis, investigation, and data curation. Bensheng Huang was involved in the equipment design. Xia Luo and Yuliang Zhao contributed to the supervision, writing original draft, methodology design, and funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, X., Li, M., Ren, J. et al. Deformation Micromechanism and Constitutive Analysis Behind the Semisolid Powder Compression of Medical Mg-Zn Alloy. JOM 74, 899–908 (2022). https://doi.org/10.1007/s11837-021-05053-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-05053-7