Abstract

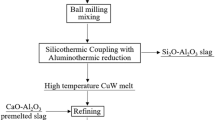

Herein, we present a novel methodology for preparing an as-cast WCu composite ingot, containing micro- and nano-size tungsten particles, through aluminothermic reduction. To synthesize the WCu composite ingot, the thermodynamics and dynamics of the Al-CuO-WO3 and Al-CuO-WO3-CaO system were investigated; thereafter, the WCu composite ingot and slag obtained through the aluminothermic reduction were systematically analyzed. The results indicate that the aluminothermic reduction occurs within a temperature range of 1223–1233 K, and the addition of CaO decreases the exothermic intensity and delays the aluminothermic reduction reaction time. The microstructure of the WCu ingot comprises a gray matrix, white tungsten particles, and black inclusions; moreover, the tungsten particle size ranges from 1 µm to 10 µm, with an average diameter of 3.52 µm and average area of 13.85 µm2. The slag mainly comprises CaAl4O7, CaWO4, and Al2O3.

Similar content being viewed by others

References

Q. Zhang, S. Liang, and L. Zhuo, J. Alloys Compd. 708, 796. (2017).

J. Zou, D. Song, H. Shi, and S. Liang, Mater. Res. Express 7(2), 26528. (2020).

Y.L. Wang, S.H. Liang, and N. Luo, Rare Met. Mater. Eng. 45(2), 329. (2016).

Q. Zhang, S. Liang, and L. Zhuo, Mater. Sci. Technol. 33(17), 2071. (2017).

Y. Guo, H. Guo, B. Gao, X. Wang, Y. Hu, and Z. Shi, J. Alloys Compd. 724, 155. (2017).

G. He, P. Zhao, S. Guo, Y. Chen, G. Liu, and J. Li, J. Alloys Compd. 579, 71. (2013).

C. Wang, S. Liang, F. Cao, and Q. Zhang, J. Alloys Compd. 816, 152506. (2019).

L. Zhuo, Q. Zhang, Y. Zhang, Z. Zhao, and J. Zhang, J. Nucl. Mater. 538, 152220. (2020).

W. Chen, L. Dong, Z. Zhang, and H. Gao, J. Mater. Sci. Mater. Electron. 27(6), 5584. (2016).

C.P. Liang, C.Y. Wu, J.L. Fan, and H.R. Gong, J. Phys. Chem. Solids 34(6), 401. (2017).

Y.P. Li, X.H. Qu, and Z.H. Zheng, Int. J. Refract. Met. Hard Mater. 5(6), 259. (2003).

G.G. Lee, G.H. Ha, and B.K. Kim, Powder Metall. 43(1), 79. (2000).

X.R. Wang, S.Z. Wei, L.J. Xu, J.W. Li, and X.Q. Shan, Adv. Powder Technol. 29(6), 1323. (2018).

E.X. Wu, C.L. Qian, Z.Q. Zou, and Y.H. Zhang, J. Cent.-South Inst. Min. Metall. 24(1), 64. (1993).

G. Flor, V. Massarotti, and R. Riccardi, Zeitschrift fur Naturforschung a 32(2), 160. (1977).

C. Cheng, Z.H. Dou, T.A. Zhang, H.J. Zhang and J. M: JOM, 69(2), 1818 (2017).

Z.R. Tang, and R.Z. Tian, Binary Alloy Phase Diagrams and Crystal Structure of Intermediate Phase (Central South University Press, Changsha, 2009), p. 51.

Acknowledgements

This research was supported by the Key Technologies R & D Program of Henan Province (Grant No. 202102210207), Chinese Postdoctoral Science Foundation (Grant No. 2020M672222), Doctoral Scientific Research Foundation of Henan University of Science and Technology (Grant No. 13480091), and Postdoctoral Scientific Research Foundation of Henan University of Science and Technology (Grant No. 13554020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, C., Song, KX., Song, ZW. et al. Synthesis of As-Cast WCu Composite Containing Micro- and Nano-Size Tungsten Particles Using Aluminothermic Reduction. JOM 74, 931–937 (2022). https://doi.org/10.1007/s11837-021-05047-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-05047-5