Abstract

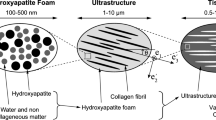

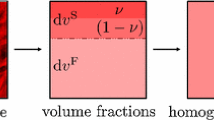

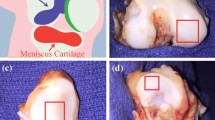

In total hip arthroplasty, the hip joint is replaced by artificial materials. The fibrous tissue that re-forms around the hip joint after surgery plays an important role in joint stability. Here, the morphological and mechanical properties of the scar tissue that forms around implants composed of either polymer and metal or ceramic are compared with native tissue removed during an initial total hip arthroplasty. Immunohistological analyses of the samples revealed different hierarchical structures of the tissues over three scales: the fiber, the fascicle, and tissue scales. At the tissue scale, microtensile tests were performed on millimetric samples and their nonlinear elastic responses identified by either an exponential law or Ogden third-order constitutive model. At the fiber scale, a patient-specific microscale finite element model was used ,including the measured morphological parameters and distinct Ogden constitutive models for the fiber and matrix composed of a mixture of fibers in ground substance.

Similar content being viewed by others

Change history

25 March 2024

A Correction to this paper has been published: https://doi.org/10.1007/s11837-024-06448-y

References

R.J. van Arkel, K.C. Ng, S.K. Muirhead-Allwood, R.T.J. Jeffers, J. Bone Joint Surg. 100(14), 1–10 (2018)

J. Parvizi, L. Sedel, M.J. Dunbar, Clin. Orthop. Relat. Res. 476(4), 678–683 (2018)

D. Hannouche, F. Devriez, J. Delambre, F. Zadegan, I. Tourabaly, L. Sedel, S. Chevret, R. Nizard, J. Bone Joint Surg. Am. 474, 520–527 (2016)

K.J. Bozic, S.M. Kurtz, E. Lau, K. Ong, T.P. Vail, D.J. Berry, J. Bone Joint Surg. Am. 91(1), 128–133 (2009)

M. Gold, A. Munjal, M. Varacallo. StatPearls (2020)

J. Hewitt, F. Guilak, R. Glisson, T. Parker Vail, J. Orthop. Res. 19, 359–364 (2001)

J.D. Hewitt, R.R. Glisson, F. Guilak, J. Arthroplasty 17, 82 (2001)

C. Vergari, P. Pourcelot, L. Holden, G. Gerard, B. Ravary-Plumioen, P. Laugier, D. Mitton, N. Crevier-Denoix, J. Biomech. 44, 719–724 (2011)

A.M. Swedberg, S.P. Reese, B.J. Ellis, S.A. Maas, J.A. Weiss, J. Biomech. 47, 3201–3209 (2014)

G.A. Holzapfel, Biomechanics of Soft Tissue. Handbook of Material Behavior (Academic, Cambridge, 2000).

N. Famaey, J.V. Sloten, Soft tissue modelling for applications in virtual surgery and surgical robotics. Comput. Methods Biomech. Biomed. Eng. 11(4), 351–366 (2008)

R.C. Hibbeler, Mechanics of Materials (Pearson Prentice Hall, Hoboken, 2011).

G. Chagnon, M. Rebouah, D. Favier, J. Mech. Phys. Solids 120, 129–160 (2014)

R.L. Armentano, J.G. Barra, J. Levenson, A. Simon, R.H. Pichel, Circ. Res. 76(3), 468–478 (1995)

G.A. Holzapfel, R. Eberlein, P. Wriggers, H.W. Weizsäcker, Comput. Methods Appl. Mech. Eng. 11(4), 351–366 (1996)

D. Garcia-Gonzalez, A. Jérusalem, S. Garzon-Hernandez, R. Zaera, A. Arias, J. Mech. Phys. Solids 112, 209 (2017)

R.W. Odgen, Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 326(1567), 565–584 (1972)

M. Merola, S. Affatato, Materials 12(3), 495 (2019)

J.A. Kiernan, Biotech. Histochem. 93, 133–148 (2018)

J. Heribert, M.D. Schaefery, Am. J. Clin. Pathol. 28(6), 646 (1957)

H. Choi, R. Vito, J. Biomech. Eng. 112(2), 153–159 (1990)

F. Gao, L. Han, Comput. Optim. Appl. 51, 259–277 (2010)

S. Bhogle, G. Mistri, B. Vesper, S. Lacey, J. Radosevich, M. Colvard, E. Budyn, CMAME 314, 19–45 (2017)

M. Smith. ABAQUS/Theory Manual, Version 6.6, Large strain elasticity. Dassault Systèmes Simulia Corp., United States (2009)

H.D. Martin, A. Savage, B.A. Braly, I.J. Palmer, D.P. Beall, B.T. Kelly, Epub 24(2), 188–95 (2008)

M.S. Hefzy, E.S. Grood, J. Biomech. Eng. 105(2), 145–153 (1983)

K.W. Simbeya, N. Shrive, C.B Frank, J.R. Matyas. A micromechanical finite element model of rabbit medial collateral ligament. Recent advances in computer methods in biomechanics and biomedical engineering, pp. 240–249 (1992)

J.A. Weiss, J.C. Gardiner, C. Bonifasi-Lista, J. Biomech. 35, 943–950 (2002)

K.J. Stewart, D.R. Pedersen, J.J. Callaghan, T.D. Brown, Orthop. J. 24, 1–8 (2004)

C. Wex, S. Arndt, A. Stoll, C. Bruns, Y. Kupriyanova, Biomed. Eng. Biomed. Technik 60(6), 577–592 (2015)

K. Laksari, M. Shafieian, K. Darvish, J. Biomech. 45(4), 642–646 (2012)

C.F. Guimarães, L. Gasperini, A.P. Marques, R.L. Reis, Nat. Rev. Mater. 5, 351–370 (2020)

Acknowledgements

The authors are grateful for the support from Agence Nationale de la recherche et de la Technologie (ANRT) CIFRE Award No. 2018/1806 in collaboration with the company CC CONTACT. The third author is now at UMS 3750, Pierre Gilles de Gennes Institute, Paris, France. The authors declare they have no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Avgeri, A., Sanders, S., Cinquin, B. et al. Homogenized Macroscale Model and Morphological Microscale Model to Understand the Varying Mechanical Properties of Scar Tissue of Hip Capsule Ligaments Grown Around Different Implant Materials. JOM 73, 2377–2389 (2021). https://doi.org/10.1007/s11837-021-04737-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04737-4