Abstract

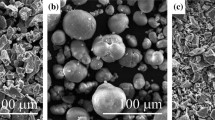

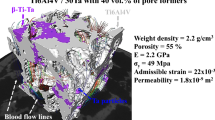

Porous Al2O3-Fap-TiO2 composite ceramics were produced by using polyvinyl butyral as pore-forming agent. A porosity of 50–53% was achieved after sintering at 1500°C for time ranges between 1 h and 5 h. The pores were shown to be interconnected with sizes ranging between 43 µm and 280 µm. The XRD investigation of the porous bodies indicated the decomposition of fluorapatite into tricalcium phosphate. The decomposition was more evident for the highly porous samples. The compressive strength of the composites improved to reach 14 MPa to 18 MPa. Such strength values would be higher than those of human cancellous bone, which would be made of the porous Al2O3-Fap-TiO2 composite produced in this study, a promising material for bone implants.

Similar content being viewed by others

References

J.H. Shepherd, and S.M. Best, JOM 69, 689 (2017).

S. Sabudina, M.A. Marzukea, and Z. Hussina, Mater. Today: Proc. 16, 1680 (2019).

A. Matamoros-Veloza, K.M. Zakir Hossain, B.E. Scammell, I. Ahmed, R. Hall, and N. Kapur, J. Mech. Behav. Biomed. Mater. 102, 103489 (2020).

T. Iwamoto, Y. Hieda, and Y. Kogai, Mater. Today Chem. 20, 100421 (2021).

B.S. Chang, C.K. Lee, K.S. Hong, H.J. Youn, H.S. Ryu, S.S. Chung, and K.W. Park, Biomaterials 21, 1291 (2000).

N. Passuti, G. Daculsi, J.M. Rogez, S. Martin, and J.V. Bainvel, Clin. Orthoped. Relat. Res. 248, 169 (1989).

I. Sopyan, M. Mel, S. Ramesh, and K.A. Khalid, Sci. Technol. Adv. Mater. 8, 116 (2007).

H.R.R. Ramay, and M. Zhang, Biomaterials 25, 5171 (2004).

E. Fidancevska, G. Ruseska, J. Bossert, Y.M. Lin, and A.R. Boccaccini, Mater. Chem. Phys. 103, 95 (2007).

I. Sopyan, A. Fadli, and M. Mel, J. Mech. Behav. Biomed. 8, 86 (2012).

C.-Y. Chiu, H.-C. Hsu, and W.-H. Tuan, Ceram. Int. 33, 715 (2007).

J.-W. Lee, Y.-H. Lee, H. Lee, Y.-H. Koh, and H.-E. Kim, Ceram. Int. 47(3), 3252 (2021).

E.K. Papynova, O.O. Shichalin, Yu.E. Skurikhina, V.B. Turkutyukov, M.A. Medkov, D.N. Grishchenko, A.S. Portnyagin, E.B. Merkulov, V.I. Apanasevich, B.I. Geltser, I.O. Evdokimov, I.S. Afonin, A.M. Zaharenko, I.G. Tananaev, and I.G. Agafonova, Ceram. Int. 45, 13838 (2019).

L. Stipniece, A. Kondratjeva, and K. Salma-Ancane, Ceram. Int. 46, 243 (2020).

J. Bieniek, and Z. Swiecki, Clin. Orthop. Relat. Res. 272, 88 (1991).

M. Saki, M.K. Narbat, A. Samadikuchaksaraei, H.B. Ghafouri, and F. Gorjipour, Yakhteh Med. J. 11(11), 55 (2009).

A. Guidara, K. Chaari, and J. Bouaziz, J. Mater. Sci. Technol. 28(112), 1130 (2012).

A. Guidara, K. Chaari, S. Kakhfakh, and J. Bouaziz, Mater. Chem. Phys. 202, 358 (2017).

F. Ben Ayed, K. Chaari, J. Bouaziz, and K. Bouzouita, C. R. Physique 7(7), 825 (2006).

A. Guidara, K. Chaari, and J. Bouaziz, J. Mater. Sci. Technol. 28(12), 1130 (2012).

S. Brunauer, P.H. Emmet, and J. Teller, J. Am. Chem. Soc. 60, 310 (1938).

D. Bortzmeyer, J. Mater. Sci. 27, 3305 (1992).

K. Chaari, F. Ben Ayed, J. Bouaziz, and K. Bouzouita, Mater. Chem. Phys. 113, 219 (2009).

M.J. Mayo, D.C. Hague, and D.-J. Chen, Mater. Sci. Eng. A 166, 145 (1993).

I. Sopyana, M. Mel, S. Ramesh, and K.A. Khalid, Sci. Technol. Adv. Mater. 8, 116 (2007).

J.R. Porter, T.T. Ruckh, and K.C. Popat, Biotechnol. Prog. 25(16), 1539 (2009).

B. Nasiri-Tabrizi, and A. Fahami, Ceram. Int. 39, 5125 (2013).

K.D. Zilnyk, G.S. Leite, H.R.Z. Sandim, and P.R. Rios, Acta Mater. 61, 5821 (2013).

U.A. Khan, A. Hussain, M. Shah, M. Shuaib, and F. Qayyum, IOP Conf. Ser. Mater. Sci. Eng. 146, 012046 (2016).

I.S.A. Fadli, Mater. Res. Innov. 13(13), 327 (2009).

Acknowledgements

The authors thank Dr. Ayadi Hajji for his help with proofreading, correcting and improving the English of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guidara, A., Chaari, K. & Bouaziz, J. Structural and Mechanical Properties of Porous Al2O3-Fap-TiO2 Composite as a Promising Material for Bone Implants. JOM 73, 2431–2439 (2021). https://doi.org/10.1007/s11837-021-04735-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04735-6