Abstract

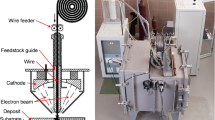

A novel coaxial electron beam wire feeding additive manufacturing technology (CAEBWAM) was proposed in our previous work to refine the microstructure and improve the mechanical properties of titanium alloys. In the present work, different post-heat treatments were performed to understand the microstructure evolution and the resultant mechanical properties of CAEBWAMed Ti-6Al-4V alloy. The as-built sample was dominated by equiaxed prior β microstructure, with the first several deposited layers containing columnar prior β grain morphology. The as-built alloy showed a mixed microstructure composed of large α′ martensite and fine α + β lamella. As the annealing temperature was increased, α′ martensite decomposed into α + β phase, while the width of the α lamellae increased, causeing an increase in the ductility and a decrease in the strength.

Similar content being viewed by others

References

G. Lütjering, and J.C. Williams, Titanium, 2nd edn. (Springer, Berlin Heidelberg, 2007), pp 1–442.

R. Biswal, X. Zhang, A.K. Syed, M. Awd, J. Ding, F. Walther, and S. Williams, Int. J. Fatigue 122, 208. (2019).

P.J. Arrazola, A. Garay, L.M. Iriarte, M. Armendia, S. Marya, and F. Le Maître, J. Mater. Process. Technol. 209, 2223. (2009).

J.K. Zhang, X.Y. Wang, S. Paddea, and X. Zhang, Mater. Des. 90, 551. (2016).

G. Lütjering, Mater. Sci. Eng., A, 243, 32 (1998).

A. Manoj, M.A. Rao, M.M. Basha, S.M. Basha, and M.R. Sankar, Mater. Today. Proc 26, 2608. (2020).

F.D. Wang, S. Williams, P. Colegrove, and A.A. Antonysamy, Metall. Mater. Trans. A 44, 968. (2012).

L. Thijs, F. Verhaeghe, T. Craeghs, J.V. Humbeeck, and J.P. Kruth, Acta Mater. 58, 3303. (2010).

M. Simonelli, Y.Y. Tse, and C. Tuck, Mater. Sci. Eng. A 616, 1. (2014).

X.Z. Shi, S.Y. Ma, C.M. Liu, Q.R. Wu, J.P. Lu, Y.D. Liu, and W.T. Shi, Mater. Sci. Eng. A 684, 196. (2017).

T. Sun, Y. Liu, S. J. Li and J. P. Li, Acta Metall. Sin. (Engl. Lett.), 32, 869 (2019).

N. Li, S. Huang, G.D. Zhang, R.Y. Qin, W. Liu, H.P. Xiong, G.Q. Shi, and J. Blackburn, J. Mater. Sci. Technol. 35, 242. (2019).

S. Cao, Q.D. Hu, A.J. Huang, Z.E. Chen, M. Sun, J.H. Zhang, C.X. Fu, Q.B. Jia, C.V.S. Lim, R.R. Boyer, Y. Yang, and X.H. Wu, J. Mater. Sci. Technol. 35, 1578. (2019).

J. C. Wang, Y. J. Liu, P. Qin, S. X. Liang, T. B. Sercombe and L. C. Zhang, Mater. Sci. Eng., A, 760, 214 (2019).

J.C. Wang, Y.J. Liu, C.D. Rabadia, S.X. Liang, T.B. Sercombe, and L.C. Zhang, J. Mater. Sci. Technol. 61, 221. (2021).

W.E. Frazier, J. Mater. Eng. Perform. 23, 1917. (2014).

J. Wang, X. Lin, J.T. Wang, H.O. Yang, Y.H. Zhou, C. Wang, Q.G. Li, and W.D. Huang, J. Alloys Compd. 768, 97. (2018).

B. Vrancken, L. Thijs, J.-P. Kruth, and J. Van Humbeeck, J. Alloys Compd. 541, 177. (2012).

S.Q. Wu, Y.J. Lu, Y.L. Gan, T.T. Huang, C.Q. Zhao, J.J. Lin, S. Guo, and J.X. Lin, J. Alloys Compd. 672, 643. (2016).

J. Wang, X. Lin, J. Q. Li, A. T. Xue, F. G. Liu, W. D. Huang and E. Q. Liang, Mater. Sci. Eng., A, 772, 138703 (2020).

K. Zhang, X. Tian, M. Bermingham, J. Rao, Q. Jia, Y. Zhu, X. Wu, S. Cao and A. Huang, Mater. Des., 184, 108191 (2019).

D. Kovalchuk, and O. Ivasishin, Profile electron beam 3-D metal printing // Additive Manufacturing for the Aerospace Industry, 1st edn. (Elsevier, Amstel Dam, 2019), pp 213–233.

J. H. Zhang, Y. Yang, S. Cao, Z. Q. Cao, D. Kovalchuk, S. Q. Wu, E. Q. Liang, X. Zhang, W. Chen, F. Wu and A. J. Huang, Acta Metall. Sin. (Engl. Lett.), 33, 1311 (2020).

S. Cao, R.K. Chu, X.G. Zhou, K. Yang, Q.B. Jia, C.V.S. Lim, A.J. Huang, and X.H. Wu, J. Alloys Compd. 744, 357. (2018).

X.C. Yan, S. Yin, C.Y. Chen, C.J. Huang, R. Bolot, R. Lupoi, M. Kuang, W.Y. Ma, C. Coddet, H.L. Liao, and M. Liu, J. Alloys Compd. 764, 1056. (2018).

X.Y. Zhang, G. Fang, S. Leeflang, A.J. Böttger, A.A. Zadpoor, and J. Zhou, J. Alloys Compd. 735, 1562. (2018).

J.Q. Xu, J. Zhu, J.K. Fan, Q. Zhou, Y. Peng, and S. Guo, Vacuum 167, 364. (2019).

J. Wang, X. Lin, M. Wang, J. Q. Li, C. Wang and W. D. Huang, Mater. Sci. Eng., A, 776, 139020 (2020).

P. Wanjara, K. Watanabe, C. de Formanoir, Q. Yang, C. Bescond, S. Godet, M. Brochu, K. Nezaki, J. Gholipour, and P. Patnaik, Adv. Mater. 9Sci. Eng 2019, 1. (2019).

J.J. Lin, Y.H. Lv, Y.X. Liu, Z. Sun, K.B. Wang, Z.G. Li, Y.X. Wu, and B.S. Xu, J. Mech. Behav. Biomed. 69, 19. (2017).

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, and M. Qian, Acta Mater. 85, 74. (2015).

F.X.G. Mur, D. Rodriguez, and J.A. Planell, J. Alloys Compd. 234, 287. (1996).

E. Sallica-Leva, R. Caram, A.L. Jardini, and J.B. Fogagnolo, J. Mech. Behav. Biomed. 54, 149. (2016).

Q. Chao, P.D. Hodgson, and H. Beladi, Metall. Mater. Trans. A 45, 2659. (2014).

P. Barriobero-Vila, V. Biancardi Oliveira, S. Schwarz, T. Buslaps and G. Requena, Acta Mater., 135, 132 (2017).

S.L. Lu, M. Qian, H.P. Tang, M. Yan, J. Wang, and D.H. StJohn, Acta Mater. 104, 303. (2016).

Z. Zhao, J. Chen, H. Tan, G.H. Zhang, X. Lin, and W.D. Huang, Scripta Mater. 146, 187. (2018).

R. Sabban, S. Bahl, K. Chatterjee, and S. Suwas, Acta Mater. 162, 239. (2019).

N. Stefansson, and S.L.S. Tin, Metall. Mater. Trans. A 34A, 691. (2003).

K. Chen, J. Luo, W. C. Han and M. Q. Li, J. Alloys Compd., 848, 156141 (2020).

J.W. Xu, W.D. Zeng, H.Y. Ma, and D.D. Zhou, J. Alloys Compd. 736, 99. (2018).

L. Ren, W.L. Xiao, W.Z. Han, C.L. Ma, and L. Zhou, Mater. Charact. 144, 1. (2018).

C. M. Liu, Y. Lu, X. J. Tian and D. Liu, Mater. Sci. Eng., A, 661, 145 (2016).

P. Åkerfeldt, M.-L. Antti and R. Pederson, Mater. Sci. Eng., A, 674, 428 (2016).

B.E. Carroll, T.A. Palmer, and A.M. Beese, Acta Mater. 87, 309 (2015).

M.J. Bermingham, L. Nicastro, D. Kent, Y. Chen, and M.S. Dargusch, J. Alloys Compd. 753, 247. (2018).

Acknowledgements

This research is supported by Frontier and Key Projects of the Chinese Academy of Sciences (QYZDJ-SSW-JSC031-01) and an internal funding source from University of Shanghai for Science and Technology.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, J., Zhang, J., Wei, Y. et al. Effect of Heat Treatment on Microstructure and Tensile Properties of Ti-6Al-4V Alloy Produced by Coaxial Electron Beam Wire Feeding Additive Manufacturing. JOM 73, 2241–2249 (2021). https://doi.org/10.1007/s11837-021-04712-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04712-z