Abstract

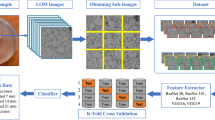

Steel’s transformation is crucial for quality improvement. The high-temperature reheating process is usually performed under oxidizing atmospheres. Therefore, decarburization is present, resulting in material losses and depreciating the material’s quality. The decarburization depth is commonly used to authenticate the quality of steel or develop prediction models. This depth is commonly measured by optical microscope techniques and following the standard E1077-01. Nonetheless, not much care has been paid to the sample size impact upon measurement metrics. The present study uses 1045-steel metallographies to analyze the influence on standard statistical tools, such as Kolmogorov-Smirnov and Anderson-Darling normality tests. Then, data were used to study the analysis of variance and honestly significant difference Tukey tests. The analysis shows that the optimal sample size for statistical analysis occurred between 20 and 30. In contrast, models must observe the RMSE’s performance as a function of the size.

Similar content being viewed by others

References

X. Lu, T. Miki, and T. Nagasaka, Corros. Sci. 139, 114 (2018). https://doi.org/10.1016/j.corsci.2018.04.045

N. Ta, L. Zhang, Q. Li, Z. Lu, and Y. Lin, Corros. Sci. 139, 355 (2018)

D.J. Young, The Nature of High Temperature Oxidation. High Temperature Oxidation and Corrosion of Metals, pp. 1–30, 2016. [Online]. Available: http://linkinghub.elsevier.com/retrieve/pii/B9780081001011000017

B. Koroušič and I.M.T. Ljubljana, Kovine Zlitine Tehnol. 30, 521 (1996)

W. Gouveia, V. Seshadri, I. Silva, and C. Silva, Adv. Mater. Res. 845, 231 (2013)

Z.J. Tao, F. Rakotovao, J.L. Grosseau-Poussard, and B. Panicaud, Adv. Mater. Res. 996, 896 (2014)

F. Zhao, C.L. Zhang, and Y.Z. Liu, Arch. Metall. Mater. 61, 1369 (2016)

A. Vackel, G. Dwivedi, and S. Sampath, JOM 67, 1540 (2015)

H.D. Alvarenga, T.V. De Putte, N. Van Steenberge, J. Sietsma, and H. Terryn, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 46, 123 (2015)

X. Liu, B. Worl, G. Tang, A. K. Silaen, J. Cox, K. Johnson, and C. Q. Zhou, Iron Steel Technol., 3045 (2018)

M. Militzer, J.J. Hoyt, N. Provatas, J. Rottler, C.W. Sinclair, and H.S. Zurob, JOM 66, 740 (2014)

L. Suárez, Y. Houbaert, X. Vanden Eynde, and R. Colás, Oxid. Met. 70, 1 (2008)

A. Ghasemi and S. Zahediasl, Int. J. Endocrinol. Metabol. 10, 486 (2012)

J.C. Mar, Biophys. Rev. 11, 89 (2019). https://doi.org/10.1007/s12551-018-0494-4

P. Galeano and D. Peña, TEST 28, 289 (2019)

L. Wasserman, All of Statistics: A Concise Course in Statistical Inference, Series. Springer Texts in Statistics (Springer, New York, 2013).

J. Janssens, Data Science at the Command Line: Facing the Future with Time-Tested Tools (O’Reilly Media, Newton, 2014).

H. Wickham and G. Grolemund, R for Data Science: Import, Tidy, Transform, Visualize, and Model Data (O’Reilly Media, Newton, 2016).

NIST/SEMATECH, e-Handbook of Statistical Methods.

Anderson–Darling Test. New York, NY: Springer New York, 2008, pp. 12–14. [Online]. Available: https://doi.org/10.1007/978-0-387-32833-1_11

V. Sadhanala, Y.-X. Wang, A. Ramdas, and R.J. Tibshirani, A higher-order kolmogorov–smirnov test, arXiv preprint arXiv:1903.10083 (2019)

American Society for Testing and Materials International, Astm e1077-14, standard test methods for estimating the depth of decarburization of steel specimens (2005)

J. Schindelin, I. Arganda-Carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, S. Preibisch, C. Rueden, S. Saalfeld, B. Schmid et al., Nat. Methods 9, 676 (2012)

Acknowledgements

The authors thank the National Laboratory “SEDEAM” for supporting this research through project nos. 235780, 271878, and 282357 and the “Tecnológico Nacional de México” for supporting this project through the founding 5441.19-P.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Disclosure

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chávez-Campos, G.M., Reyes-Archundia, E., Vergara-Hernández, H.J. et al. A Sample Size Statistical Analysis and Its Impact on Decarburization Measurements Metrics. JOM 73, 2031–2038 (2021). https://doi.org/10.1007/s11837-021-04697-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04697-9