Abstract

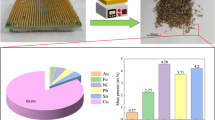

Using ammonium chloride as a chlorination agent, indium in waste liquid-crystal display panels was successfully extracted by microwave-assisted chloride metallurgy under vacuum pressure. The optimal conditions for indium extraction from pure indium oxide were explored through single-factor and orthogonal experiments, achieving an indium extraction ratio of 98.91% when the temperature was 500°C, the Cl/In molar ratio was 8, and the heating duration was 3 min for pure In2O3. The Cl/In molar ratio exhibited the most important effect on the indium extraction ratio, followed by the heating temperature and duration. When extracting indium from waste liquid-crystal display panel powder (–13 µm) after ball milling, the indium extraction ratio was nearly 79.46% when using an ammonium chloride mass ratio of 0.6 wt.%, temperature of 500°C, and heating duration of 3 min. Excess gaseous hydrogen chloride reacts with ammonia to form ammonium chloride during the condensation, thereby avoiding emission of hydrogen chloride into the environment. The results of this work indicate that this technology represents a promising option for the extraction of indium from waste liquid-crystal display panels with a very short heating duration and relatively low chlorination agent loss, as well as no harmful gas emissions.

Similar content being viewed by others

Abbreviations

- LCD:

-

Liquid-crystal display

- ITO:

-

Indium tin oxide

- ∆G :

-

Gibbs free energy

- ∆H :

-

Enthalpy

- ∆S :

-

Entropy

- T :

-

Absolute temperature

- Q :

-

Reaction entropy

- k :

-

Reaction rate constant

- A :

-

Frequency factor

- Ea :

-

Activation energy

- R :

-

Ideal gas constant

References

S.-W. Hung, J.-M. Tsai, M.-J. Cheng, and P.-C. Chen, Technol. Soc. 34, 9. (2012).

L. Zhang, B. Wu, Y. Chen, and Z. Xu, J. Clean. Prod. 162, 1472. (2017).

A. Amato, and F. Beolchini, J. Environ. Manage. 225, 1. (2018).

A.M. Rashad, Constr. Build. Mater. 93, 1236. (2015).

K. Kim, and K. Kim, J. Clean. Prod. 227, 199. (2019).

K. Grant, F.C. Goldizen, P.D. Sly, M.-N. Brune, M. Neira, M. Van Den Berg, and R.E. Norman, Lancet Glob Health 1, e350. (2013).

L. Ciacci, T.T. Werner, I. Vassura, and F. Passarini, J. Ind. Ecol. 23, 426. (2019).

A. Akcil, I. Agcasulu, and B. Swain, Resour. Conserv. Recy. 149, 622. (2019).

K.-L. Lin, W.-K. Chang, T.-C. Chang, C.-H. Lee, and C.-H. Lin, J. Clean. Prod. 17, 1499. (2009).

K. Huang, J. Guo, and Z. Xu, J. Hazard. Mater. 164, 399. (2009).

I. Birloaga, I. De Michelis, F. Ferella, M. Buzatu, and F. Vegliò, Waste Manag. 33, 935. (2013).

I.H. Kuong, J. Li, J. Zhang, and X. Zeng, Environ. Sci. Technol. 53, 1394. (2019).

Y. Li, N. Zhu, X. Wei, J. Cui, P. Wu, P. Li, J. Wu, and Y. Lin, Process Saf. Environ. Prot. 133, 137. (2020).

Q. Song, L. Zhang, and Z. Xu, J. Hazard. Mater. 381, 120973. (2020).

L. Zhang, B. Wu, Y. Chen, and Z. Xu, J. Clean. Prod. 162, 141. (2017).

Y. He, E. Ma, and Z. Xu, J. Hazard. Mater. 268, 185. (2014).

J. Guan, S. Wang, H. Ren, Y. Guo, H. Yuan, X. Yan, J. Guo, W. Gu, R. Su, B. Liang, G. Gao, Y. Zhou, J. Xu, and Z. Guo, RSC Adv. 5, 102836. (2015).

E. Ma, R. Lu, and Z. Xu, Green Chem. 14, 3395. (2012).

H.H. Nejad, M. Kazemeini, and M. Fattahi, Adv. Mater. Res. 548, 186. (2012).

H.B. Trinh, J.-C. Lee, Y.-J. Suh, and J. Lee, Waste Manag. 114, 148. (2020).

M. Bhattacharya, and T. Basak, Energy 97, 306. (2016).

M. Fattahi, M. Kazemeini, F. Khorasheh, and A. Rashidi, Chem. Eng. J. 250, 14. (2014).

E. Ma, and Z. Xu, J. Hazard. Mater. 263, 610. (2013).

S.S. Lam, R.K. Liew, Y.M. Wong, P.N.Y. Yek, N.L. Ma, C.L. Lee, and H.A. Chase, J. Clean. Prod. 162, 1376. (2017).

S.Y. Foong, R.K. Liew, Y. Yang, Y.W. Cheng, P.N.Y. Yek, W.A. Wan Mahari, X.Y. Lee, C.S. Han, D.-V.N. Vo, Q. Van Le, M. Aghbashlo, M. Tabatabaei, C. Sonne, W. Peng, and S.S. Lam, Chem. Eng. J. 389, 124401. (2020).

Y.V. Bykov, K.I. Rybakov, and V.E. Semenov, J. Phys. D: Appl. Phys. 34, R55. (2001).

F. Mushtaq, R. Mat, and F.N. Ani, Renew. Sust. Energy Rev. 39, 555. (2014).

A. Goldstein, R. Ruginets, and L. Geifman, Ceram. Int. 35, 1297. (2009).

N. Yoshikawa, K. Seki, N. Inoue, S. Komarov, K.-I. Kashimura, T. Fujii, and H. Fukushima, Mater. Chem. Phys. 234, 281. (2019).

C.-H. Lee, M.-K. Jeong, M. Fatih Kilicaslan, J.-H. Lee, H.-S. Hong, and S.-J. Hong, Waste Manag. 33, 730. (2013).

M. Assefi, S. Maroufi, R.K. Nekouei, and V. Sahajwalla, J. Clean. Prod. 180, 814. (2018).

Acknowledgements

We gratefully acknowledge the financial support from Natural Science Foundation of China (51678353, 52070127), Shanghai Natural Science Foundation (20ZR1421100), Gaoyuan Discipline of Shanghai–Environmental Science and Engineering (Resource Recycling Science and Engineering), Cultivation discipline fund of Shanghai Polytechnic University (XXKPY1601), Eastern Scholar Professorship Grant, Shanghai Polytechnic University Program (EGD19XQD02), Shanghai Youth Science and Technology Talent Sailing Plan (17YF1425600), Special Found for Basic Business Expenses of Public Welfare Research Institutes at the Central Level (2016T10), and Henan Key Laboratory of Coal Green Conversion (Henan Polytechnic University, CGCF201803).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, S., Guan, J., Yuan, H. et al. Behavior and Mechanism of Indium Extraction from Waste Liquid-Crystal Display Panels by Microwave-Assisted Chlorination Metallurgy. JOM 73, 1290–1300 (2021). https://doi.org/10.1007/s11837-021-04590-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04590-5