Abstract

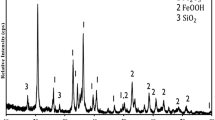

Iron recovery from copper slag generated during copper production by the pyrometallurgical method has been widely investigated to achieve resource utilization. Liberation and enrichment of metallic iron from reductively roasted copper slag were explored in this work. Results show that metallic iron, quartz solid solution, and cristobalite solid solution are the main phases in reductively roasted copper slag, and most metallic iron particles are wrapped by silica. A concentrate with 74.39% Fe content and 83.14% Fe recovery is obtained through grinding–magnetic separation. For comparison, the metallic iron particles are liberated through alkali leaching of silica. The Fe content in leaching residue reaches 78.17% by removing 88.96% SiO2 and further increases to 90.45% by magnetic separation with Fe recovery of 85.20%. Therefore, alkali leaching–magnetic separation is suitable for treating reductively roasted copper slag because of the high Fe content in concentrate and comprehensive recovery of silica.

Similar content being viewed by others

References

M.E. Schlesinger, M.J. King, K.C. Sole, and W.G. Davenport, Extractive Metallurgy of Copper, 5th edn. (Elsevier Pte Ltd., Singapore, 2011)

K. Holland, R.H. Eric, P. Taskinen, and A. Jokilaakso, K. Holland, R.H. Eric, P. Taskinen, and A. Jokilaakso, Miner. Eng. 133, 35 (2019).

Y. Tsunazawa, C.Z. Liu, R. Toi, T. Okura, and C. Tokoro, Y. Tsunazawa, C.Z. Liu, R. Toi, T. Okura, and C. Tokoro, Miner. Process. Extr. Metall. 128, 248 (2019).

B. Gorai, and R.K. Jana, B. Gorai, and R.K. Jana, Premchand. Resour. Conserv. Recycl. 39, 299 (2003).

H.W. Zhang, L. Sun, L. Fu, and Z.G. Ji, H.W. Zhang, L. Sun, L. Fu, and Z.G. Ji, JOM 71, 1997 (2019).

I. Gaballah, S. El Raghy, and C. Gleitzer, I. Gaballah, S. El Raghy, and C. Gleitzer, J. Mater. Sci. 13, 1971 (1978).

S. Gyurov, Y. Kostova, G. Klitcheva, and A. Ilinkina, S. Gyurov, Y. Kostova, G. Klitcheva, and A. Ilinkina, Waste Manage. Res. 29, 157 (2011).

B. Kim, S. Jo, D. Shin, J. Lee, and S. Jeong, B. Kim, S. Jo, D. Shin, J. Lee, and S. Jeong, Int. J. Miner. Process. 124, 124 (2013).

A. Warczok, and T.A. Utigard, A. Warczok, and T.A. Utigard, Can. Metall. Q. 37, 27 (1998).

S. Gyurov, N. Marinkov, Y. Kostova, D. Rabadjieva, D. Kovacheva, C. Tzvetkova, G. Gentscheva, and I. Penkov, S. Gyurov, N. Marinkov, Y. Kostova, D. Rabadjieva, D. Kovacheva, C. Tzvetkova, G. Gentscheva, and I. Penkov, Int. J. Miner. Process. 158, 1 (2017).

S.W. Zhou, Y.G. Wei, B. Li, and H. Wang, S.W. Zhou, Y.G. Wei, B. Li, and H. Wang, J. Cleaner Prod. 217, 423 (2019).

H.F. Yang, L.L. Jing, and C.G. Dang, H.F. Yang, L.L. Jing, and C.G. Dang, Chin. J. Nonferrous Met. 21, 1165 ((in Chinese)) (2011).

T.J. Chun, G. Mu, Z. Di, H.M. Long, C. Ning, and D. Li, T.J. Chun, G. Mu, Z. Di, H.M. Long, C. Ning, and D. Li, Arch. Metall. Mater. 63, 299 (2018).

Z.Q. Guo, D.Q. Zhu, J. Pan, W.J. Yao, W.Q. Xu, and J.N. Chen, Z.Q. Guo, D.Q. Zhu, J. Pan, W.J. Yao, W.Q. Xu, and J.N. Chen, JOM 69, 1688 (2017).

S.W. Li, J. Pan, D.Q. Zhu, Z.Q. Guo, J.W. Xu, and J.L. Chou, S.W. Li, J. Pan, D.Q. Zhu, Z.Q. Guo, J.W. Xu, and J.L. Chou, Powder Technol. 347, 159 (2019).

R.M. Jiao, P. Xing, C.Y. Wang, B.Z. Ma, Y.Q. Chen, Int. J. Miner., Metall. Mater. 24, 974 (2017).

Z.Q. Guo, D.Q. Zhu, J. Pan, and F. Zhang, Z.Q. Guo, D.Q. Zhu, J. Pan, and F. Zhang, J. Cleaner Prod. 187, 910 (2018).

D.M. Croker, M. Loan, and B.K. Hodnett, D.M. Croker, M. Loan, and B.K. Hodnett, Cryst. Growth Des. 8, 4499 (2008).

V.L. Rayzman, A.V. Aturin, I.Z. Pevzner, V.M. Sizyakov, L.P. Ni, and I.K. Filipovich, V.L. Rayzman, A.V. Aturin, I.Z. Pevzner, V.M. Sizyakov, L.P. Ni, and I.K. Filipovich, JOM 55, 47 (2003).

P. Smith, P. Smith, Hydrometallurgy 98, 162 (2009).

X.B. Li, H.Y. Wang, Q.S. Zhou, T.G. Qi, G.H. Liu, Z.H. Peng, and Y.L. Wang, X.B. Li, H.Y. Wang, Q.S. Zhou, T.G. Qi, G.H. Liu, Z.H. Peng, and Y.L. Wang, Trans. Nonferrous Met. Soc. China 29, 416 (2019).

X.B. Li, H.Y. Wang, Q.S. Zhou, T.G. Qi, G.H. Liu, Z.H. Peng, and Y.L. Wang, X.B. Li, H.Y. Wang, Q.S. Zhou, T.G. Qi, G.H. Liu, Z.H. Peng, and Y.L. Wang, Trans. Nonferrous Met. Soc. China 29, 186 (2019).

X.B. Li, H.Y. Wang, Q.S. Zhou, T.G. Qi, G.H. Liu, and Z.H. Peng, X.B. Li, H.Y. Wang, Q.S. Zhou, T.G. Qi, G.H. Liu, and Z.H. Peng, Waste Manage. 87, 798 (2019).

B.A. Wills, and T.J. Napier-Munn, Mineral Processing Technology (Elsevier Science & Technology Books, Amsterdam, 2006)

R.C. Wang, Y.C. Zhai, Z.Q. Ning, and P.H. Ma, R.C. Wang, Y.C. Zhai, Z.Q. Ning, and P.H. Ma, Trans. Nonferrous Met. Soc. China 24, 1928 (2014).

J. Luo, G.H. Li, T. Jiang, Z.W. Peng, M.J. Rao, Y.B. Zhang, J. Cent. South Univ. (Engl. Ed.) 23, 1883 (2016).

T.J. Chun, C. Ning, H.M. Long, J.X. Li, and J.L. Yang, T.J. Chun, C. Ning, H.M. Long, J.X. Li, and J.L. Yang, JOM 68, 2332 (2016).

Acknowledgement

This work was financially supported by the China Postdoctoral Science Foundation (2019M662733), National Natural Science Foundation of China (51874219), and National Key Research and Development Program of China (2018YFC1901502).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, H., Zhang, X., Shen, L. et al. Liberation and Enrichment of Metallic Iron from Reductively Roasted Copper Slag. JOM 73, 1013–1022 (2021). https://doi.org/10.1007/s11837-021-04570-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04570-9