Abstract

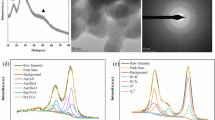

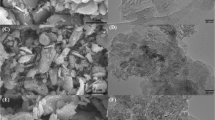

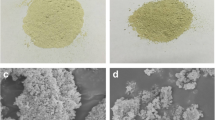

Arsenic–rhenium filter cake, one of the main wastes produced by copper smelting systems, is a vital source of rhenium (Re). Using traditional hydrometallurgy methods, rhenium can be leached by sulfuric acid solution with the help of oxidants. However, the residual oxidants can seriously affect the efficiency and lifetime of the extractants and ion-exchange resins. We herein propose a novel method to leach rhenium through a displacement reaction using copper sulfate solution, thereby avoiding the use of oxidants. The results show that Re element exists in the arsenic–rhenium filter cake in two forms: Re2S7 and (As,Re)S amorphous. The rhenium leaching efficiency can reach 93.18%, and the kinetic data fit the shrinking core model. The leaching rate is controlled first by chemical reaction, with an apparent activation energy of 78.46 kJ mol−1. Afterwards, the leaching kinetics of rhenium fits an internal diffusion model. The results provide theoretical guidance on how to make full use of waste residues from copper smelting systems.

Similar content being viewed by others

References

Z.W. Zhao and H.G. Li, Metall. Mater. Trans. B. 39, 519. (2008).

P. Raj, G. Singh, A.W. Thomas, and A. Scott, Braymiller. Int. J Refract. Met. H. 50, 79. (2015).

Y.Y. Shen, Y. Jiang, X.Y. Qiu, and S.L. Zhao, JOM 69, 1976. (2017).

Z.S. Abisheva, A.N. Zagorodnyaya, and N.S. Bekturganov, Hydrometallurgy 109, 1. (2011).

R.R. Srivastava, M.S. Kim, and J.C. Lee, Ind. Eng. Chem. Res. 55, 8197. (2016).

E.I. Gedgagov, S.V. Zakhar’yan, and D.V. Zakhar’yan, Theor. Found. Chem. Eng. 52, 912. (2018).

H.S. Kim, J.S. Park, S.Y. Seo, T. Tran, and M.J. Kim, Hydrometallurgy 156, 158. (2015).

E.E. Maltseva, A.A. Blokhin, Y.V. Murashkin, and M.A. Mikhaylenko, Russ. J Non-ferr. Met. 58, 463. (2017).

J. Yañez, S. Torres, D. Sbarbaro, R. Parra, and C. Saavedra, IFAC-PapersOnLine 51, 251. (2018).

S. Virolainen, M. Laatikainen, and T. Sainio, Hydrometallurgy 158, 74. (2015).

S.K. Mamo, M. Elie, M.G. Baron, A.M. Simons, and J. Gonzalez-Rodriguez, Sep. Purif. Technol. 212, 150. (2019).

A.O. Gezerman and B.D. Çorbacıoğlu, Sur. Eng. 31, 641. (2015).

A. Tuncuk, V. Stazi, A. Akcil, E.Y. Yazici, and H. Deveci, Miner. Eng. 25, 28. (2012).

S.V. Zakhar’yan and E.I. Gedgagov, Theor. Found. Chem. Eng. 47, 637. (2013).

F. Zhou, Q. Liu, J. Feng, J.X. Su, X. Liu, and R. Chi, Sep. Purif. Technol. 217, 24. (2019).

H.U. Sverdrup, A.H. Olafsdottir, K.V. Ragnarsdottir, and D. Koca, BioPhys. Eco. Resour. Qual. 3, 7. (2018).

O. Levenspiel, Ind. Eng. Chem. Res. 38, 4140. (1999).

S.S. Javaherian, H. Aghajani, and H. Tavakoli, Miner. Process. Extra. M. 127, 182. (2018).

M.R. Altıokka, H. Akalın, N. Melek, and S. Akyalçın, Ind. Eng. Chem. Res. 49, 12379. (2010).

M. Li, X.W. Zhang, Z.G. Liu, Y.H. Hu, M.T. Wang, J. Liu, and J.P. Yang, Hydrometallurgy 140, 71. (2013).

Acknowledgements

This work was financially supported by the National Nature Science Foundation of China (Nos. 51874257 and 51374185).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xu, S., Shen, Y., Yu, T. et al. High-Efficiency Oxidant-Free Leaching of Rhenium from Arsenic–Rhenium Filter Cake. JOM 73, 913–922 (2021). https://doi.org/10.1007/s11837-020-04560-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04560-3