Abstract

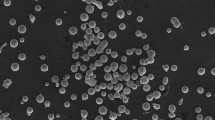

The limited inter-lamellar bonding in the conventional thermal-sprayed 304SS coating usually leads to much lower corrosion and wear resistance than their bulk counterparts. In this study, Mo-clad stainless steel 304SS-17Mo powders prepared by mechanical alloying were used for plasma spraying to generate ultra-high-tempertature droplets to deposit the coatings with enhanced inter-lamellar bonding. The temperature at the interface between the molten splats and the stainless steel was calculated by numerical simulation, and the surface temperature of in-flight particles was measured by a commercial thermal spray particle diagnostic system. The microstructures of the coatings after etching were characterized to reveal inter-lamellar bonding. The adhesive and cohesive strengthes of the coatings were estimated by tensile and scratch tests. The measurement of the in-flight particle temperature reveals the possibility of creating a self-bonding effect, which is confirmed by microstructure examination, high adhesion over 66 MPa, and cohesion of 221 MPa.

Similar content being viewed by others

References

A. Ohmori and C.J. Li, Thin Solid Films 201, 241 (1991).

C.J. Li and A. Ohmori, J. Therm. Spray Technol. 11, 365 (2002).

C.J. Li, G.J. Yang, and C.X. Li, J. Therm. Spray Technol. 22, 192 (2012).

A. Ohmori, C.J. Li, and Y. Arata, Trans. Join. Weld. Res. Inst. 19, 259 (1990).

Z.H. Chu, W.X. Deng, W. Zheng, Y.Y. Zhou, Y. Zhang, J.X. Xu, and L. Gao, J. Therm. Spray Technol. 29, 1111 (2020).

S.A. Galedari, A. Mahdavi, F. Azarmi, Y. Huang, and A. McDonald, J. Therm. Spray Technol. 28, 645 (2019).

K. Sridhar, M.B. Deshmukh, A.S. Khanna, and A. Gasser, J. Therm. Spray Technol. 9, 377 (2000).

R.T. Allsop, T.J. Pitt, and J.V. Hardy, Metallurgia 63, 125 (1961).

S. Kitahara and A. Hasui, J. Vac. Sci. Technol. 11, 747 (1974).

J.M. Houben, G.G. Liempd, 10th International Thermal Spray Conference (German Welding Society, 1983), pp. 66–71.

L. Li, X.Y. Wang, G. Wei, A. Vaidya, H. Zhang, and S. Sampath, Thin Solid Films 468, 113 (2004).

H. Zhang, X.Y. Wang, and L.L. Zheng, Int. J. Heat Mass Transf. 44, 4579 (2001).

C.J. Li, C.X. Li, and G.J. Yang, J. Therm. Spray Technol. 15, 717 (2006).

S.P. Wang, G.X. Wang, and E.F. Matthys, Int. J. Heat Mass Transf. 41, 1177 (1998).

C.I. Helgesson, Nature 209, 706 (1966).

F.N. Longo, J. Vac. Sci. Technol. 12, 773 (1975).

S. Sampath, G.A. Bancke, and H. Herman, Surf. Eng. 5, 293 (1989).

S. Deshpande, S. Sampath, and H. Zhang, Surf. Coat. Technol. 200, 5395 (2006).

Y.Z. Xing, C.J. Li, Q. Zhang, C.X. Li, and G.J. Yang, J. Am. Ceram. Soc. 91, 3931 (2008).

S. Hao, C.J. Li, and G.J. Yang, J. Therm. Spray Technol. 20, 160 (2011).

G.J. Yang, C.X. Li, S. Hao, and C.J. Li, Surf. Coat. Technol. 235, 841 (2013).

S.W. Yao, C.J. Li, J.J. Tian, and G.J. Yang, Acta Mater. 119, 9 (2016).

V. Pershin, M. Lufifitha, S. Chandra, and J. Mostaghimi, J. Therm. Spray Technol. 12, 370 (2003).

J. Wang, X.T. Luo, C.J. Li, N. Ma, and M. Takahashi, Surf. Coat. Technol. 371, 36 (2019).

J. Wang, C.J. Li, G.J. Yang, and C.X. Li, J. Therm. Spray Technol. 26, 1 (2016).

K.V. Niessen and M. Gindrat, J. Eng. Gas Turb. Power. 133, 445 (2010).

G. Mauer, A. Hospach, and R. Vasen, Surf. Coat. Technol. 220, 219 (2013).

C.B. Huang, L.Z. Du, and W.G. Zhang, J. Alloys Compd. 479, 777 (2009).

J.J. Tian, S.W. Yao, X.T. Luo, C.X. Li, and C.J. Li, Acta Mater. 110, 19 (2016).

C.B. Huang, L.Z. Du, and W.G. Zhang, J. Therm. Spray Technol. 23, 463 (2014).

J.J. Tian, S.W. Yao, S.L. Zhang, and C.J. Li, Surf. Coat. Tech. 335, 52 (2018).

J.J. Tian, Y.K. Wei, C.X. Li, G.J. Yang, and C.J. Li, J. Therm. Spray Technol. 27, 232 (2018).

W.J. Tobler and S. Virtanen, Corros. Sci. 48, 1585 (2006).

G. Zheng and S. Kumar, JOM 70, 1535 (2018).

J.H. Perepezko and R. Sakidja, JOM 65, 307 (2013).

B. Yilbas, A. Kumar, and B. Bhushan, JOM 66, 37 (2014).

ASTM Designation C633-01, Am. Soc. Test. Mater. 3, 1 (2001).

Y. Lahmar-Mebdoua, A. Vardelle, P. Fauchais, and D. Gobin, Int. J. Therm. Sci. 49, 522 (2010).

Y. Lahmar-Mebdoua, A. Vardelle, P. Fauchais, and D. Gobin, High Temp. Mater. Proc. 11, 191 (2007).

Z. Bergant and J. Grum, J. Therm. Spray Technol. 18, 380 (2009).

X.Y. Dong, X.T. Luo, S.L. Zhang, and C.J. Li, J. Therm. Spray Technol. 29, 173 (2020).

Y. Arata, A. Ohmori, and C.J. Li, Trans. Join. Weld. Res. Inst. 17, 311 (1988).

G.M. Hamilton and L.E. Goodman, J. Appl. Mech. 33, 371 (1966).

X.C. Wang, S.L. Chen, and B. Shen, Adv. Mater. Res. 797, 719 (2013).

P.O. Aiyedun, F.N. Nwaneto, and A.E. Adeleke, Aust. J. Basic Appl. Sci. 6, 6312 (2010).

Acknowledgements

The present project is financially supported by National Natural Science Foundation of China (Grant Nos. U1837201; 52031010) and Jiangxi Key R&D Program of General Project (Grant No. 20202BBE53010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liao, XJ., Zhang, L., Dong, XY. et al. Self-Bonding Effect Development for Plasma Spraying of Stainless Steel Coating Through Using Mo-Clad Stainless Steel Powders. JOM 72, 4613–4623 (2020). https://doi.org/10.1007/s11837-020-04395-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04395-y