Abstract

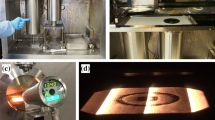

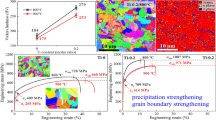

The microstructure and mechanical properties of Mg-1.5Zn-0.2Ca-0.2Ce alloy sheets processed via accumulated extrusion bonding (AEB) at 523 K were examined in this study. To investigate the microstructure evolution, samples corresponding to various process stages were taken from six locations parallel to the extrusion direction. Many twin boundaries were observed at the initial extrusion stage, and subsequently dynamic recrystallization (DRX) (especially ‘twin-assisted’ DRX and continuous DRX) was activated. With increasing strain, the matrix grains were gradually transformed into new DRXed grains, and the grains were significantly refined to 0.55 μm, whereas the grains grew to 3.1 μm outside the die. After the AEB process, the sheet exhibited almost the same texture as that of the as-received sheet with basal poles tilted to the extrusion direction by ~ ± 30°. The tensile test results revealed that, compared with the as-received sheet, the yield strength of AEBed sheets was improved as much as 50 MPa, resulting mainly from the grain refinement.

Similar content being viewed by others

References

B. Huang, New alloy materials-Magnesium alloys (China: China Railway Publishing House, 2017), pp. 1–405.

J. Koike, T. Kobayashi, T. Mukai, H. Watanabe, M. Suzuki, K. Maruyama, and K. Higashi, Acta Mater. 51, 2055 (2003).

M. Drits, Z. Sviderskaya, L. Rokhlin, and N. Nikitina, Met. Sci. Heat Treat. 21, 887 (1979).

D. Mizer and B.C. Peters, Metall. Mater. Trans. B 3, 3262 (1972).

W. Liu, J. Dong, X. Song, J. Belnoue, F. Hofmann, W. Ding, and A. Korsunsky, Mater. Sci. Eng., A 528, 2250 (2011).

H. Huang, G. Yuan, Z. Chu, and W. Ding, Mater. Sci. Eng. A 560, 241 (2013).

X. Zeng, Y. Zhang, C. Lu, W. Ding, Y. Wang, and Y. Zhu, J Alloys Compd. 395, 213 (2005).

L. Liu, X. Chen, F. Pan, Z. Wang, W. Liu, P. Cao, T. Yan, and X. Xu, Mater. Sci. Eng. A 644, 247 (2015).

T. Peng, Q.D. Wang, and J.B. Lin, Mater. Sci. Eng. A 516, 23 (2009).

K. Guan, B. Li, Q. Yang, X. Qiu, Z. Tian, D. Zhang, D. Zhang, X. Niu, W. Sun, X. Liu, and J. Meng, J Alloys Compd. 735, 1737 (2018).

T. Zhang, H. Cui, X. Cui, E. Zhao, Y. Pan, R. Feng, Q. Jia, and J. Zhao, J Alloys Compd. 784, 1130 (2019).

X. Heng, Y. Zhang, W. Rong, Y. Wu, and L. Peng, Mater. Des. 169, 107666 (2019).

R. Zheng, T. Bhattacharjee, A. Shibata, T. Sasaki, K. Hono, M. Joshi, and N. Tsuji, Scr. Mater. 131, 1 (2017).

Y. Zeng, B. Jiang, D. Huang, J. Dai, F. Pan, and J. Magnes, Alloy 1, 297 (2013).

R. Alizadeh, R. Mahmudi, A. Ngan, Y. Huang, and T. Langdon, Mater. Sci. Eng. A 651, 786 (2016).

F. Meng, J.M. Rosalie, A. Singh, H. Somekawa, and K. Tsuchiya, Scr. Mater. 78–79, 57 (2014).

J. Xu, Q. Su, C. Wang, X. Wang, D. Shan, B. Guo, and T.G. Langdon, Adv. Eng. Mater. 21, 1800961 (2019).

T.C. Lowe and R.Z. Valiev, JOM 56, 64 (2004).

J. Lin, X. Wang, W. Ren, X. Yang, and Q. Wang, J. Mater. Sci. Technol. 32, 783 (2016).

Q. Wang, Y. Mu, J. Lin, L. Zhang, and H.J. Roven, Mater. Sci. Eng. A 699, 26 (2017).

H. Watanabe, T. Mukai, K. Ishikawa, and K. Higashi, Scr. Mater. 46, 851 (2002).

W. Kim, S. Hong, Y. Kim, S. Min, H. Jeong, and J. Lee, Acta Mater. 51, 3293 (2003).

F. Schwarz, C. Eilers, and L. Krüger, Mater. Charact. 105, 144 (2015).

X. Luo, T. Huang, Y. Wang, Y. Xin, and G. Wu, Sci. Rep. 9, 5428 (2019).

Q.F. Wang, X. Xiao, X. Chen, and W. Chen, Mater. Sci. Forum. 551–552, 249 (2007).

M.-Y. Zhan, Y.-Y. Li, and W.-P. Chen, Trans. Nonferrous Met. Soc. China 18, 309 (2008).

T. Han, G. Huang, Q. Deng, G. Wang, B. Jiang, A. Tang, Y. Zhu, and F. Pan, J Alloys Compd. 745, 599 (2018).

G. Wang, G. Huang, X. Chen, Q. Deng, A. Tang, B. Jiang, and F. Pan, Mater. Sci. Eng. A 705, 46 (2017).

Y. Chai, B. Jiang, J. Song, B. Liu, G. Huang, D. Zhang, and F. Pan, Mater. Sci. Eng., A 746, 82 (2019).

S. Biswas, B. Beausir, L.S. Toth, and S. Suwas, Acta Mater. 61, 5263 (2013).

S.M. Fatemi and A. Zarei-Hanzaki, Mater. Sci. Eng. A 708, 230 (2017).

F. Guo, D. Zhang, X. Yang, L. Jiang, S. Chai, and F. Pan, Mater. Sci. Eng. A 607, 383 (2014).

S. Fatemi-Varzaneh, A. Zarei-Hanzaki, and J. Cabrera, J Alloys Compd. 509, 3806 (2011).

Y. Huang, Y. Wang, X. Meng, L. Wan, J. Cao, L. Zhou, and J. Feng, J. Mater. Proc. Technol. 249, 331 (2017).

N.L. Li, G.J. Huang, R.L. Xin, and Q. Liu, Sci. China Technol. Sci. 55, 490 (2012).

S.H. Park, S.-H. Kim, H.S. Kim, and B.S. You, J. Alloys Compd. 648, 615 (2015).

M.G. Jiang, C. Xu, H. Yan, G.H. Fan, T. Nakata, C.S. Lao, R.S. Chen, S. Kamado, E.H. Han, and B.H. Lu, Acta Mater. 157, 53 (2018).

J.H. Lee, T. Lee, S.W. Song, S.H. Park, and C.S. Lee, Mater. Sci. Eng. A 619, 328 (2014).

H. Yan, S. Xu, R. Chen, S. Kamado, T. Honma, and E. Han, J Alloys Compd. 566, 98 (2013).

H. Zhang, W. Jin, J. Fan, W. Cheng, H.J. Roven, B. Xu, and H. Dong, Mater. Lett. 135, 31 (2014).

T. Mukai, H. Somekawa, T. Inoue, and A. Singh, Scr. Mater. 62, 113 (2010).

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China (Nos. 51905366, 51604181, 51671041, 51671041 and U1610253), the Key Research and Development Program of Shanxi Province (No. 201603D111004), the Fund for Shanxi “1331 Project” Key Subjects Construction, Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi (No. 2017157) and Taiyuan University of Science and Technology Scientific Research Initial Funding (20182030 and 20192008). This work was also supported by the Collaborative Innovation Center of Taiyuan Heavy Machinery Equipment and Special Professor Support Program for Outstanding Young Scholars in Shanxi Province.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, T., Zou, J., Ma, L. et al. Microstructure Evolution and Mechanical Properties of Mg-1.5Zn-0.2Ca-0.2Ce Alloy Processed by Accumulated Extrusion Bonding. JOM 72, 2597–2602 (2020). https://doi.org/10.1007/s11837-020-04181-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04181-w