Abstract

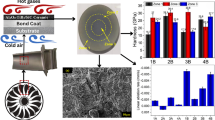

HfB2-ZrB2 based ultra-high temperature ceramics (UHTCs) are used as protective tiles for leading edges and nose cones of the hypersonic vehicles that face harsh re-entry conditions. In the present work, the effect of SiC (20 vol.%) and carbon nanotube (CNT, 6 vol.%) incorporation on the room temperature damage initiation and wear damage tolerance of HfB2-ZrB2-based ceramics, consolidated via spark plasma sintering (SPS), is assessed. The wear rate decreased by almost > 90% in CNT-reinforced HfB2-ZrB2–SiC composites (for both scratch and fretting tests), and a significant increase in the Hertzian contact pressure (from ~ 15 GPa, in case of fretting to ~ 21 GPa, in case of scratch wear) and scratch hardness (from ~ 27 GPa to ~ 46 GPa, respectively) was observed with synergistic reinforcements of SiC and CNT. The study examines synergistic interfacial strengthening by SiC and CNT reinforcement in HfB2-ZrB2 ceramic composites as potential materials for aerospace applications where damage initiation and tolerance are issues.

Similar content being viewed by others

References

E. Zapata-Solvas, D.D. Jayaseelan, P.M. Brown, W.E. Lee, Adv. Appl. Ceram. 114, 407 (2015).

W.G. Fahrenholtz, E.J. Wuchina, W.E. Lee, and Y. Zhou, Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications (Hoboken: Wiley, 2014), p. 458.

W.G. Fahrenholtz, G.E. Hilmas, I.G. Talmy, and J.A. Zaykoski, J. Am. Ceram. Soc. 90, 1347 (2007).

N. Kumar, G. Gautam, R. Kumar, and A. Mohan, Tribol. Int. 97, 313 (2016).

A. Nisar and K. Balani, Adv. Eng. Mater. 19(5), 1600713 (2017).

R. Jaworski, P. Lech, R. Francine, K. Stefan, and P. Fabrice, Surf. Coat. Technol. 202, 2644 (2008).

K. Pereira, T. Yue, and M.A. Wahab, Tribiol. Int. 110, 222 (2017).

K. Sikdar, S. Shekhar, and K. Balani, Wear 318, 177 (2014).

S. Chakraborty, A.R. Mallick, D. Debnath, and P.K. Das, Int. J. Refract. Met. Hard Mater. 48, 150 (2015).

D. Debnath, S. Chakraborty, A.R. Mallick, R.K. Gupta, A. Ranjan, and P.K. Das, Adv. Appl. Ceram. 114, 45 (2015).

D. Ghosh, G. Subhash, R. Radhakrishnan, and T.S. Sudarshan, Acta Mater. 56, 3011 (2008).

A. Nisar and K. Balani, Coatings 7, 110 (2017).

S. Awasthi, C. Prabha, and K. Balani, Mater. Res. Bull. 99, 61 (2018).

M. Haas, K. El, U. Cihak-bayr, A. Pauschitz, and M. Gröschl, Tribiol. Int. 141, 105912 (2020).

E. Eakins, D.D. Jayaseelan, and W.E. Lee, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 42, 878 (2011).

A. Fantetti, L.R. Tamatam, M. Volvert, I. Lawal, L. Liu, L. Salles, M.R.W. Brake, C.W. Schwingshackl, and D. Nowell, Tribiol. Int. 138, 111 (2019).

B. Basu, J. Vleugels, and O. Van Der Biest, Wear 250–251, 631 (2001).

C.X. Li, J. Xia, and H. Dong, Wear 261, 693 (2006).

A. Nisar, S. Ariharan, and K. Balani, Direction 15, 55 (2015).

F. Alam, A. Kumar, A.K. Patel, R.K. Sharma, and K. Balani, JOM 67, 688 (2015).

R. Maurya, B. Kumar, S. Ariharan, J. Ramkumar, and K. Balani, Mater. Des. 98, 155 (2016).

B. Bhushan, Introduction to Tribology (New York: Wiley, 2013), p. 368.

M. Amiri and M.M. Khonsari, Entropy 12, 1021 (2010).

S. Fouvry, T. Liskiewicz, Ph. Kapsa, S. Hannel, and E. Sauger, Wear 255, 287 (2003).

A. Ramalho and J.C. Miranda, Wear 260, 361 (2006.)

S. Awasthi, S. Goel, C.P. Pandey, and K. Balani, JOM 69, 227 (2017).

M.M. Opeka, I.G. Talmy, E.J. Wuchina, J.A. Zaykoski, and S.J. Causey, J. Eur. Ceram. Soc. 19, 2405 (1999).

K. Balani, S.P. Harimkar, A. Keshri, Y. Chen, and N.B. Dahotre, A. Agarwal, Acta Mater. 56, 5984 (2008).

A.T. Akono, N.X. Randall, and F.J. Ulm, J. Mater. Res. 27, 485 (2012).

Acknowledgements

The authors acknowledge the Advanced Center for Material Science, IIT Kanpur, for use of the SEM, microscratch testing and optical profilometer facility. KB acknowledges funding from Impacting Research Innovation and Technology (IMPRINT, sanction number: IMP/2018/000739) from the Science & Engineering Research Board (SERB), Department of Science and Technology, Government of India. Drs. S. Ariharan, Rita Maurya and Fahad Alam are acknowledged for their technical assistance throughout this work.

Author information

Authors and Affiliations

Contributions

KB conceptualized the idea and procured the funding. SD planned and performed the experiments and prepared the first draft; SA and AN assisted in the analysis. SD, KB, SA and AN edited the paper.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dubey, S., Awasthi, S., Nisar, A. et al. Role of Interfaces in Damage Initiation and Tolerance of Carbon Nanotube-Reinforced HfB2-ZrB2 Ceramics. JOM 72, 2207–2218 (2020). https://doi.org/10.1007/s11837-020-04164-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04164-x