Abstract

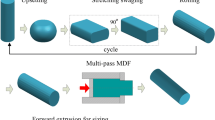

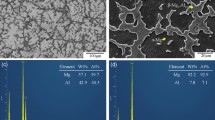

Fine grain modification is an important means for preparing lightweight and low-plasticity materials, including magnesium alloys. This paper proposes an accumulative alternating back extrusion (AABE) technique for preparing magnesium alloy materials. Metallographic microscopy and electron backscatter diffraction were used to test the resulting magnesium alloy samples and indicated that AABE can effectively refine microstructure and improve uniformity in local areas of the sample. After one pass of AABE, the upper part of the specimen was mainly characterized by recrystallization, with a high degree of refinement. The lower part showed coexisting recrystallization refinement and twinning refinement, which are less preferable. The mean grain size after applying five passes of AABE was half that of the samples subjected to only one pass. AABE is a novel and effective method for preparing high-performance magnesium alloy materials.

Similar content being viewed by others

References

J. He, B. Jiang, Q. Yang, X. Li, X. Xia, and F. Pan, J. Alloys Compd. 301, 621 (2015).

M. Arul Kumar, A.K. Kanjarla, S.R. Niezgoda, R.A. Lebensohn, and C.N. Tomé, Acta Mater. 84, 349 (2015).

R.B. Figueiredo, S.J. Poggiali Flávia, L.P. Silva Cláudio, P.R. Cetlin, and T.G. Langdon, J. Mater. Sci. 51, 3013 (2016).

E. Bagherpour, N. Pardis, M. Reihanian, and R. Ebrahimi, Int. J. Adv. Manuf. Technol. 100, 1647 (2019).

R. Jahadi, M. Sedighi, and H. Jahed, Mater. Manuf. Process. 32, 1375 (2017).

K.R. Gopi, H.S. Nayaka, and S. Sahu, J. Mater. Eng. Perform. 25, 3737 (2016).

T. Masuda and Z. Horita, Mater. Trans. 60, 1104 (2019).

S. Panda, L.S. Toth, J.J. Fundenberger, O. Perroud, J. Guyon, J. Zou, and T. Grosdidier, Mater. Charact. 123, 159 (2017).

L. Zhang, Q. Wang, W. Liao, W. Guo, B. Ye, W. Li, H. Jiang, and W. Ding, Mater. Charact. 126, 17 (2017).

J. Lin, X. Wang, W. Ren, X. Yang, and Q. Wang, J. Mater. Sci. Technol. 32, 783 (2016).

S.M. Fatemi-Varzaneh and A. Zarei-Hanzaki, Mater. Sci. Eng. A 504, 104 (2009).

S.M. Fatemi-Varzaneh, A. Zarei-Hanzaki, M. Naderi, and A.A. Roostaei, J. Alloys Compd. 507, 207 (2010).

S.M. Fatemi-Varzaneh, A. Zarei-Hanzaki, J.M. Cabrera, and P.R. Calvillo, Mater. Chem. Phys. 149, 339 (2015).

N. Haghdadi, A. Zarei-Hanzaki, H.R. Abedi, D. Abou-Ras, M. Kawasaki, and A.P. Zhilyaev, Mater. Sci. Eng. A 651, 269 (2016).

K. Huang and R.E. Loge, Mater. Des. 111, 548 (2016).

K. Huang, K. Marthinsen, Q. Zhao, and R.E. Logé, Prog. Mater Sci. 92, 284 (2018).

Acknowledgements

This project is supported by the National Natural Science Foundation of China (Grant No. 51975166) and the Fundamental Research Foundation for Universities of Heilongjiang Province (No. LGYC2018JQ011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Li, F., Li, X.W. et al. Preparation Mechanism of Fine-Grained Magnesium Alloys by Accumulative Alternating Back Extrusion. JOM 72, 2578–2585 (2020). https://doi.org/10.1007/s11837-020-04109-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04109-4