Abstract

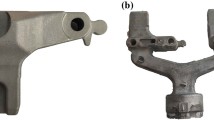

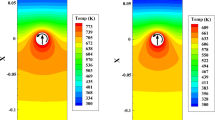

A highly parallelized mesoscale solidification model based on a cellular automaton method was coupled with a macroscale process model to predict grain structure during directional solidification. The macroscale thermal model and a nucleation parameter (maximum nucleation density) for René N500 were verified and calibrated using temperature profiles obtained via thermocouples in step-geometry castings and grain structures analyzed by electron backscatter diffraction (EBSD), respectively. The calibrated model was then applied to a laboratory-scale turbine blade to predict its grain structures. The predicted grain sizes agreed with experimental measurements under different casting conditions. The established bulk nucleation parameter based on the simple geometry can be directly transferred to complex geometries. Grain calculations without accurate estimations of nucleation on the chill plate can still provide reasonably good predictions. Overall, a viable path to calibrate model inputs for grain structure models based on simple geometry, where faster iterations can be achieved, is demonstrated.

Similar content being viewed by others

References

G.K. Bouse and J.R. Mihalisan, Metallurgy of Investment Cast Superalloy Components (New York: Academic Press, Inc., 1989).

H.J. Dai, H.B. Dong, N. D’Souza, J.-C. Gebelin, and R.C. Reed, Metall. Mater. Trans. A 42, 3439 (2011).

A.J. Torroba, O. Koeser, L. Calba, L. Maestro, E. Carreño-Morelli, M. Rahimian, S. Milenkovic, I. Sabirov, and J. LLorca, Integr. Mater. Manuf. Innov. 3, 369 (2014).

Q. Xu, C. Yang, H. Zhang, X. Yan, N. Tang, and B. Liu, Metals (Basel). 8, 632 (2018).

H.J. Dai, J.C. Gebelin, N. D’Souza, P.D. Brown, and H.B. Dong, Int. J. Cast Met. Res. 22, 54 (2009).

S.M. Seo, I.S. Kim, J.H. Lee, C.Y. Jo, H. Miyahara, and K. Ogi, Met. Mater. Int. 15, 391 (2009).

D. Szeliga, K. Kubiak, A. Burbelko, M. Motyka, and J. Sieniawski, J. Mater. Eng. Perform. 23, 1088 (2014).

G. Matache, D.M. Stefanescu, C. Puscasu, E. Alexandrescu, and A. Bührig-Polaczek, Int. J. Cast Met. Res. 28, 323 (2015).

M. Rezaei, A. Kermanpur, and F. Sadeghi, J. Cryst. Growth 485, 19 (2018).

H.J. Dai, J.C. Gebelin, M. Newell, R.C. Reed, N. D’Souza, P.D. Brown, and H.B. Dong, in Proceedings of the International Symposium Superalloys, vol. 367 (2008).

S.F. Gao, L. Liu, N. Wang, X.B. Zhao, J. Zhang, and H.Z. Fu, Metall. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 43, 3767 (2012).

X. Meng, Q. Lu, J. Li, T. Jin, X. Sun, J. Zhang, Z. Chen, Y. Wang, and Z. Hu, J. Mater. Sci. Technol. 28, 214 (2012).

D. Pan, Q. Xu, B. Liu, J. Li, H. Yuan, and H. Jin, JOM 62, 30 (2010).

M. Rappaz and C.-A. Gandin, Acta Metall. Mater. 41, 345 (1993).

M. Rappaz and C.A. Gandin, MRS Bull. 19, 20 (1994).

C.A. Gandin, J.L. Desbiolles, M. Rappaz, and P. Thévoz, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 30, 3153 (1999).

S. Bogner, E. Ivanova, M. Müller, F. Wang, D. Ma, and A. Bührig-Polaczek, Metals 5, 1971 (2015).

X.-M. Li, J.-Y. Zhang, B. Wang, Z.-M. Ren, and G.-Z. Zhou, J. Cent. South Univ. Technol. 18, 23 (2011).

P. Carter, D.C. Cox, C.A. Gandin, and R.C. Reed, Mater. Sci. Eng. A 280, 233 (2000).

N. Wang, L. Liu, S. Gao, X. Zhao, T. Huang, J. Zhang, and H. Fu, J. Alloys Compd. 586, 220 (2014).

A. Kermanpur, N. Varahram, P. Davami, and M. Rappaz, Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 31, 1293 (2000).

L. Yuan and P.D. Lee, Acta Mater. 60, 4917 (2012).

L. Yuan and P.D. Lee, Model. Simul. Mater. Sci. Eng. 18, 55008 (2010).

W. Wang, P.D. Lee, and M. McLean, Acta Mater. 51, 2971 (2003).

W. Kurz, B. Giovanola, and R. Trivedi, Acta Metall. 34, 823 (1986).

C.-A. Gandin, R.J. Schaefer, and M. Rappax, Acta Mater. 44, 3339 (1996).

C.-A. Gandin, M. Rappaz, and R. Tintillier, Metall. Mater. Trans. A 25, 629 (1994).

Acknowledgements

The authors gratefully acknowledge technical support from Brian Ellis, Brody Smith, Jeremiah Faulkner, and Chris McLasky and valuable discussions with James Maughan, Christopher Hanslits, Mark Thompson, Judson Marte, Ade Makinde, and Michael Gigliotti.

Funding

Funding was provided by General Electric.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Durga, A., Dai, H., Huang, S. et al. Grain Structure Prediction for Directionally Solidified Superalloy Castings. JOM 72, 1785–1793 (2020). https://doi.org/10.1007/s11837-020-04080-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04080-0