Abstract

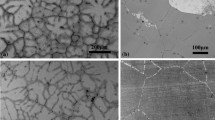

The effects of macro-alloying of Al and Ag on the age-hardening behavior and precipitates microstructure of a Mg-4Sn alloy aged at 160°C were investigated. All the alloys exhibited a similar hardening trend, and achieved the peak-aged state around 230 h. The peak-aged Mg-4Sn alloy contained several thin basal plates and a few Mg2Sn laths heterogeneously distributed within the matrix, which resulted in a poor hardening response. The Mg-4Sn-4Al alloy exhibited an improved age-hardening response by the enhanced precipitation process and an increased volume fraction of the Mg2Sn precipitates. An addition of 1.5 wt.% Ag to the ternary alloy significantly refined the Mg2Sn precipitates. In the peak-aged Mg-4Sn-4Al-1.5Ag alloy, Al and Ag solute atoms still supersaturated the α-Mg matrix, thus further improving the hardness by the solid-solution strengthening effect. Some Ag atoms segregated with the Mg2Sn precipitates, and minor Ag-enriched particles were also formed. In contrast, Al distributed more uniformly in the matrix.

Similar content being viewed by others

References

I.J. Polmear, D. St. John, J.-F. Nie, and M. Ma, Light Alloys (London: Elsevier Butterworth-Heinemann, 2017).

F. Wang, J.J. Bhattacharyya, and S.R. Agnew, Mater. Sci. Eng. A 666, 114 (2016).

B.-Y. Liu, N. Yang, J. Wang, M. Barnett, Y.-C. Xin, D. Wu, R.-L. Xin, B. Li, R.L. Narayan, J.-F. Nie, J. Li, E. Ma, and Z.-W. Shan, J. Mater. Sci. Technol. 34, 1061 (2018).

J.F. Nie, Scr. Mater. 48, 1009 (2003).

S.H. Huang, J. Mater. Eng. Perform. 27, 3199 (2018).

S. Behdad, L. Zhou, H.B. Henderson, M.V. Manuel, Y. Sohn, A. Agarwal, and B. Boesl, Mater. Sci. Eng. A 651, 854 (2016).

C.L. Mendis, C.J. Bettles, M.A. Gibson, S. Gorsse, and C.R. Hutchinson, Philos. Mag. Lett. 86, 443 (2006).

X. Huang, A. Wu, Q. Li, and W. Huang, Mater. Sci. Eng. A 661, 233 (2016).

W. Li, X. Huang, X. Li, and W. Huang, J. Alloys Compd. 766, 584 (2018).

H. Baker and H. Okamoto, ASM Handbook Volume 3: Alloy Phase Diagrams (Cleveland: ASM International, 1992).

J.B. Zhang, L.B. Tong, C. Xu, Z.H. Jiang, L.R. Cheng, S. Kamado, and H.J. Zhang, Mater. Sci. Eng. A 708, 11 (2017).

Z. Li, M. Chen, W. Li, H. Zheng, C. You, D. Liu, and F. Jin, J. Alloys Compd. 702, 290 (2017).

L.Y. Jiang, W.J. Huang, F. Guo, Y.H. Zhang, D.F. Zhang, and Q.C. Liu, Mater. Sci. Eng. A 752, 145 (2019).

W. Li, X. Huang, and W. Huang, Mater. Sci. Eng. A 692, 75 (2017).

T.T. Sasaki, K. Oh-ishi, T. Ohkubo, and K. Hono, Scr. Mater. 55, 251 (2006).

X. Huang, G. Han, and W. Huang, Materials 11, 628 (2018).

X. Huang and W. Huang, J. Appl. Crystallogr. 49, 2031 (2016).

K. Hono, C.L. Mendis, T.T. Sasaki, and K. Oh-Ishi, Scr. Mater. 63, 710 (2010).

A.L. Bowles, H. Dieringa, C. Blawert, N. Hort, and K.U. Kainer, Mater. Sci. Forum 488–489, 135 (2005).

X. Huang and W. Huang, Mater. Charact. 151, 260 (2019).

X. Huang, Y. Du, W. Li, Y. Chai, and W. Huang, J. Alloys Compd. 696, 850 (2017).

X.-F. Huang and W.-Z. Zhang, Mater. Sci. Eng. A 552, 211 (2012).

J. Clark, Acta Metall. Mater. 16, 141 (1968).

J. Geng, X. Gao, X.Y. Fang, and J.F. Nie, Scr. Mater. 64, 506 (2011).

C.Q. Liu, H.W. Chen, H. Liu, X.J. Zhao, and J.F. Nie, Acta Mater. 144, 590 (2018).

J.F. Nie, Metall. Mater. Trans. A 43A, 1 (2012).

X. Gao and J.F. Nie, Scr. Mater. 58, 619 (2008).

E. Doernberg, A. Kozlov, and R. Schmid-Fetzer, J. Phase Equilib. Diff. 28, 523 (2007).

N.N. Greenwood and A. Earnshaw, Chemistry of the Elements, 2nd ed. (Oxford: Butterworth-Heinemann, 1997).

C.L. Mendis, C.J. Bettles, M.A. Gibson, and C.R. Hutchinson, Mater. Sci. Eng. A 435–436, 163 (2006).

C.L. Mendis, B.C. Muddle, and J.F. Nie, Philos. Mag. Lett. 86, 755 (2006).

Y.K. Kim, D.H. Kim, W.T. Kim, and D.H. Kim, Mater. Lett. 113, 50 (2013).

Z.Z. Shi and W.Z. Zhang, J. Appl. Crystallogr. 48, 1745 (2015).

J.A. Yasi, L.G. Hector, and D.R. Trinkle, Acta Mater. 59, 5652 (2011).

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant No. 51401135. The authors would like to express their gratitude to Dr. Guomin Han at the Institute of Applied Physics and Computational Mathematics, Beijing, and Mr. Sufyan Naseem, Gangming Chen at Sichuan University for their constructive discussions and proofreading English expressions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Huang, X., Huang, S. Macro-alloying Effects of Al and Ag on the Age-Hardening Behavior and Precipitates Microstructure of a Mg-4Sn Alloy. JOM 72, 1384–1394 (2020). https://doi.org/10.1007/s11837-019-03980-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03980-0