Abstract

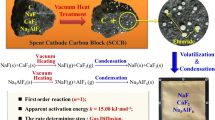

Waste silicon carbide side block (WSB) from aluminum reduction cells are considered as hazardous materials since they contain a large amount of soluble fluoride salts. The storage of this material outside or in landfills is detrimental for the environment. A joint temperature–vacuum controlling process for treating WSB is proposed in this paper. Thermodynamic analysis by FactSage 7.0, and a series of experimental investigation and characteristics tests on the product materials by SEM and XRD were carried out. The results showed that the fluoride in the waste side block was completely volatilized, and the silicon nitride was also decomposed after being treated at 1600°C under a vacuum of 10 Pa. The soluble fluoride concentration was reduced from 2216 mg L−1 to 3.9 mg L−1, and the silicon carbide content was increased from 76.7 wt.% to 91.5 wt.%.

Similar content being viewed by others

References

S. Kasuriya and P. Thavorniti, Mater. Sci. Forum 534, 1073 (2007).

M.I. Jones, E. Ron, M. Jim, Y. Zhou, H. Hyuga, Y. Yoshizawa, and K. Hirao, Key Eng. Mat. 403, 235 (2009).

H. Bhatt, K.Y. Donaldson, D. Hasselman, and R.T. Bhatt, J. Am. Ceram. Soc. 75, 334 (2010).

X.Y. Xia and J. Li, Adv. Mater. Res. 146, 1473 (2011).

Z. Wang, E. Skybakmoen, and T. Grande, J. Am. Ceram. Soc. 2, 1296 (2010).

N.V. Grachev, E.P. Orlov, D.V. Mukhin, and V.P. Kryuchkova, Refract. Ind. Ceram. 47, 78 (2006).

B.I. Silveira, A.E. Dantas, J.E. Blasquez, and R.K.P. Santos, J. Hazard. Mater. 89, 177 (2002).

M.J. Palmieri, L.F. Andrade, M.V.C. Trento, M.W. FariaEleutério, J. Luber, L.C. Davide, and S. Marcussi, Water Air Soil Pollut. 227, 1 (2016).

L.F. Andrade, L.C. Davide, L.S. Gedraite, J.M.S. Campos, and H. Azevedo, Ecotoxicol. Environ. Saf. 74, 2065 (2011).

L.F. Andrade, L.C. Davide, and L.S. Gedraite, Ecotoxicol. Environ. Saf. 73, 626 (2010).

B.D. Turner, P.J. Binning, and S.W. Sloan, J. Contam. Hydrol. 95, 110 (2008).

N. Li, Adv. Mater. Res. 881, 1660 (2014).

G. Hollywell and R. Breault, JOM 65, 1441 (2013).

B. Mazumder and S.R. Devi, J. Environ. Sci. Eng. 50, 203 (2008).

S. Huang, Light Met. 4, 29 (2009).

H. Arnljot, Proceedings of 35th International ICSOBA Conference 1081 (2017).

B. Mazumder and S.R. Devi, J. Appl. Chem. 3, 24 (2013).

D. Yu and K. Chattopadhyay, Can. Metall. Q. 55, 251 (2016).

P. VonKrüger, Light Met. 49, 275 (2011).

L. Birry, S. Leclerc, and S. Poirier, Light Met. 77, 467 (2016).

D.F. Lisbona, C. Somerfield, and K.M. Steel, Hydrometallurgy 134, 132 (2013).

V. Gomes, P.Z. Drumond, J.O.P. Neto, and A.R. Lira, Light Met. 142, 1057 (2005).

R.K. Womack, JOM 51, 14 (1999).

C.Y. Hu, S.L. Lo, W.H. Kuan, and Y.D. Lee, Water Res. 39, 895 (2005).

E.J. Reardon and Y. Wang, Environ. Sci. Technol. 34, 3247 (2000).

J.Z. Song, Northeastern University 1, 6 (2010).

Acknowledgements

This study was supported by the China’s Aluminum Industry Sustainable Development Strategy (2018-XY-14) and Key R&D Program of Ningxia Hui Autonomous Region (2018BDE02050). The authors are grateful to the reviewers who helped to improve the paper by many pertinent comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, M., Guo, X., Liu, W. et al. Phase Transition of Waste Silicon Carbide Side Block from Aluminum Smelters During Vacuum High-Temperature Detoxification Process. JOM 72, 2697–2704 (2020). https://doi.org/10.1007/s11837-019-03978-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03978-8