Abstract

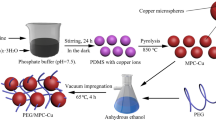

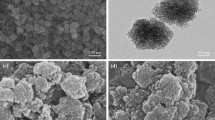

Novel mesoporous carbon microspheres (MCMS), which exhibited a large surface area and were developed by the pyrolysis of polydopamine microspheres (PDAMS), were used as a supporting material for polyethylene glycol (PEG) to prepare a new type of efficient form-stable phase-change material (MCMS-PEG). Using a simple vacuum impregnation strategy, the preparation of polydopamine microspheres via a biomimetic method was facile, simple and environmentally friendly. Characterization of MCMS-PEG was performed by scanning electron microscopy (SEM), x-ray diffraction (XRD), x-ray photoelectron spectroscopy (XPS), differential scanning calorimetry (DSC), Fourier-transform infrared spectroscopy (FT-IR) and thermogravimetric analysis (TGA). The results suggested that MCMS-PEG possessed high latent heats of 112.08 J/g during the melting process and 107.34 J/g during the solidification process. Additionally, MCMS-PEG presented an enhanced thermal conductivity and excellent thermal stability. Therefore, the novel mesoporous carbon microspheres developed in this study could be used as efficient supports for the preparation of shape-stabilized phase-change materials.

Similar content being viewed by others

References

Q. Zhang and J. Liu, Nano Energy 2, 863 (2013).

H. Zhao, M. Zhou, L. Wen, and Y. Lei, Nano Energy 13, 790 (2015).

A. Laaouatni, N. Martaj, R. Bennacer, M. Lachi, M.E. Omari, and M.E. Ganaoui, Energy Build. 187, 50 (2019).

L.M. Zhong, X.W. Zhang, Y. Luan, G. Wang, Y.H. Feng, and D.L. Feng, Sol. Energy 107, 63 (2014).

H.X. Ji, D.P. Sellan, M.T. Pettes, X.H. Kong, J.Y. Ji, L. Shi, and R.S. Ruoff, Energy Environ. Sci. 7, 1185 (2014).

K.P. Lin, Y.P. Zhang, X. Xu, H.F. Di, R. Yang, and P.H. Qin, Energy Build. 37, 215 (2005).

Z.Y. Wang, F. Qiu, W.S. Yang, and X.D. Zhao, Renew. Sustain. Energy Rev. 52, 645 (2015).

C.Y. Wang, L.L. Feng, W. Li, J. Zheng, W.H. Tian, and X.G. Li, Sol. Energy Mater. Sol. Cells 105, 21 (2012).

Y.Y. Yang, W.B. Kong, and X.F. Cai, Energy Build. 158, 37 (2018).

A. Biçer and A. Sarı, Sol. Energy Mater. Sol. Cells 102, 125 (2012).

C.L. Wang, K.L. Yeh, C.W. Chen, Y. Lee, H.L. Lee, and T. Lee, Appl. Energy 191, 239 (2017).

K. Tomosuke and O. Masaru, Phys. Chem. Chem. Phys. 16, 5495 (2014).

X. Py, R. Olives, and S. Mauran, Int. J. Heat Mass Transf. 44, 2727 (2001).

Y. Jiang, E.Y. Ding, and G.K. Li, Polymer 43, 117 (2002).

Y. Chen, H. Ding, B.F. Wang, Q. Shi, J.K. Gao, Z.X. Cui, and Y.C. Wan, J. Clean. Prod. 208, 951 (2019).

X.B. Huang, X. Chen, A. Li, D. Atinafu, H.Y. Gao, W.J. Dong, and G. Wang, Chem. Eng. J. 356, 641 (2019).

B. Xu, C.X. Zhang, C.H. Chen, J. Zhou, C.D. Lu, and Z.J. Ni, J. Therm. Anal. Calorim. 133, 1417 (2018).

X.G. Zhang, R.L. Wen, C. Tang, B.G. Wu, Z.H. Huang, X. Min, Y.T. Huang, Y.G. Liu, M.H. Fang, and X.W. Wu, Energy Build. 130, 113 (2016).

G.H. Jia, Z. Li, P. Liu, and Q.S. Jing, J. Non-Cryst. Solids 482, 192 (2018).

X.G. Zhang, Z.Y. Yin, D.Z. Meng, Z.H. Huang, R.L. Wen, Y.T. Huang, X. Min, Y.G. Liu, M.H. Fang, and X.W. Wu, Renew. Energy 112, 113 (2017).

X. Guo, Y.H. Huang, and J.Z. Cao, Energy Build. 58, 1257 (2018).

A. Sarı, A. Bicer, A. Al-Ahmed, F.A. Al-Sulaiman, M.H. Zahir, and S.A. Mohamedb, Sol. Energy Mater. Sol. Cells 179, 353 (2018).

A. Sarı, Energy Build. 96, 193 (2015).

N. Justh, B. Berke, K. László, L.P. Bakos, A. Szabó, K. Hernádi, and I.M. Szilágyi, Appl. Surf. Sci. 453, 245 (2018).

T.T. Qian, J.H. Li, W.W. Feng, and H.E. Nian, Energy Convers. Manag. 143, 96 (2017).

K.L. Ai, Y.L. Liu, C.P. Ruan, L.H. Lu, and G.Q. Lu, Adv. Mater. 25, 998 (2013).

D.V. Kosynkin, A.L. Higginbotham, A. Sinitskii, J.R. Lomeda, A. Dimiev, B.K. Price, and J.M. Tour, Nature 458, 872 (2009).

J.L. Dalsin, B.H. Hu, B.P. Lee, and P.B. Messersmith, J. Am. Chem. Soc. 125, 4253 (2003).

H. Lee, S.M. Dellatore, W.M. Miller, and P.B. Messersmith, Science 318, 426 (2007).

Q.R. Zhang, Y.X. Li, Q.G. Yang, H. Chen, X.Q. Chen, T.F. Jiao, and Q.M. Peng, J. Hazard. Mater. 342, 732 (2018).

J.K. Gao, L.A. Hou, G.H. Zhang, and P. Gu, J. Hazard. Mater. 286, 325 (2015).

D. Kołodyńska, J. Krukowska, and P. Thomas, Chem. Eng. J. 307, 353 (2017).

W.H. Zhang, S.Y. Mao, H. Chen, L. Huang, and R.L. Qiu, Bioresour. Technol. 147, 545 (2013).

G. Moreno-Fernandez, S. Perez-Ferreras, L. Pascual, I. Llorente, J. Ibañez, and J.M. Rojo, Electrochim. Acta 268, 121 (2018).

B. Zhao, D. O’Connor, J.L. Zhang, T.Y. Peng, Z.T. Shen, D.C.W. Tsang, and D.Y. Hou, J. Clean. Prod. 174, 977 (2018).

W. Liu, H. Jiang, and H. Yu, Chem. Rev. 115, 12251 (2015).

Z.J. Feng and L.Z. Zhu, Front. Environ. Sci. Eng. 12, 1 (2018).

A. Sarı, A. Bicer, F.A. Al-Sulaiman, A. Karaipekli, and V.V. Tyagi, Energy Build. 164, 166 (2018).

Y. Deng, J.H. Li, T.T. Qian, W.M. Guan, Y.L. Li, and X.P. Yin, Chem. Eng. J. 295, 427 (2016).

X.G. Zhang, R.L. Wen, C. Tang, B.G. Wu, Z.H. Huang, X. Min, Y.T. Huang, Y.G. Liu, M.H. Fang, and X.W. Wu, Energy Build. 130, 113 (2016).

C.E. Li, H. Yu, Y. Song, and M. Zhao, Renew Energy 121, 45 (2018).

Y.H. Jia, S.L. Shi, J. Liu, S.M. Su, Q. Liang, X.B. Zeng, and T.S. Li, Appl Sci. 8, 1019 (2018).

T.T. Qian, J.H. Li, H.W. Ma, and J. Yang, Sol. Energy Mater. Sol. Cells 132, 29 (2015).

L.L. Feng, C.Y. Wang, P. Song, H.B. Wang, and X.R. Zhang, Appl. Therm. Eng. 90, 952 (2015).

Y. Chen, Z.X. Cui, H. Ding, Y.C. Wan, Z.B. Tang, and J.K. Gao, Int. J. Mol. Sci. 19, 3055 (2018).

L.L. Feng, W. Zhao, J. Zheng, S. Frisco, P. Song, and X.G. Li, Sol. Energy Mater. Sol. Cells 95, 3550 (2011).

R.L. Wen, X.G. Zhang, Y.T. Huang, Z.Y. Yin, Z.H. Huang, M.H. Fang, Y.G. Liu, and X.W. Wu, Energy Build. 139, 197 (2017).

T.T. Qian, J.H. Li, H.W. Ma, and J. Yang, Sol. Energy Mater. Sol. Cells 132, 29 (2015).

T. Khadiran, M.Z. Hussein, Z. Zainal, and R. Rusli, J Taiwan Inst. Chem. E 55, 189 (2015).

M.B. Clark, J.A. Gardella, T.M. Schultz, D.G. Patil, and L. Salvati, Anal. Chem. 62, 949 (1990).

I. Kaminska, M.R. Das, Y. Coffinier, J. Niedziolka-Jonsson, J. Sobczak, P. Woisel, J. Lyskawa, M. Opallo, R. Boukherroub, and S. Szunerits, App. Mater. Interfaces 4, 1016 (2012).

Z.Y. Xi, Y.Y. Xu, L.P. Zhu, Y. Wang, and B.K. Zhu, J. Membr. Sci. 327, 244 (2009).

X.B. Huang, X. Chen, A. Li, D. Atinafu, H.Y. Gao, W.J. Dong, and G. Wang, Chem. Eng. J. 356, 641 (2019).

Acknowledgements

The authors are grateful for the financial support of the National Natural Science Foundation of China (Nos. 41776105 and 51606168), the Science and Technology Planning Project of Zhoushan of China (Nos. 2015C41010 and 2018C21017) and the Zhejiang Provincial Natural Science Foundation of China (No. LY18E060007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, Y., Liu, Y., Chen, Z. et al. Efficient Shape-Stabilized Phase-Change Material Based on Novel Mesoporous Carbon Microspheres as a Matrix for Polyethylene Glycol: Preparation and Thermal Properties. JOM 71, 4547–4555 (2019). https://doi.org/10.1007/s11837-019-03787-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03787-z