Abstract

The hot deformation response of third-generation titanium aluminides with compositions Ti-45Al-5Nb-0.2B-0.2C and Ti-45Al-10Nb-0.2B-0.2C (hereafter referred to as Ti-45-5 and Ti-45-10, respectively) has been investigated through isothermal compression tests. The tests have been carried out in the \( (\alpha_{2} + \gamma ) \) and \( (\alpha + \gamma ) \) phase regions for both alloys. The flow response, kinetics and microstructural evolution during hot deformation have been analysed in detail, and the outcome of the investigation has been used to predict the processing window for the two alloys. The optimum processing domain for the Ti-45-10 alloy is situated 50°C higher than that of the Ti-45-5 alloy. The post-mortem analyses of the microstructures revealed that deformation in the \( (\alpha_{2} + \gamma ) \) phase field leads to dynamic recrystallisation of all the phases resulting in a distribution of very fine grains. Microstructural features of both alloys depict kinking and breaking of the lamellae for the equivalent temperatures. The higher strength of the Ti-45-10 alloy has been attributed to shifting of the order-disorder transition toward the higher temperature side. In the \( (\alpha + \gamma ) \) region, the fraction of \( \alpha \) phase increases more for the Ti-45-10 alloy compared with the Ti-45-5 alloy.

Similar content being viewed by others

References

R.J.E. Glenny, J.E. Northwood, and B. Smith, Int. Mater. Rev. 20, 1 (1975).

C. Estrada, Sci. Tech. Año XIII 22, 297 (2007).

S. Zghal, S. Naka, and A. Couret, Acta Mater. 45, 3005 (1997).

N.A. Nochovnaya, P.V. Panin, A.S. Kochetkov, and K.A. Bokov, Met. Sci. Heat Treat. 56, 364 (2014).

R. Gerling, F.P. Schimansky, A. Stark, A. Bartels, H. Kestler, L. Cha, C. Scheu, and H. Clemens, Intermetallics 16, 689 (2008).

A. Lasalmonie, Intermetallics 14, 1123 (2006).

H. Nickel, N. Zheng, A. Elschner, and W.J. Quadakkers, Mikrochim. Acta 39, 23 (1995).

C.J. Zhan, T.-H. Yu, and C.-H. Koo, Mater. Trans. 47, 2588 (2006).

D.B. Lee, K.B. Park, and M. Nakamura, Met. Mater. Int. 8, 319 (2002).

M. Oehring, A. Stark, J.D.H. Paul, T. Lippmann, and F. Pyczak, Mater. Sci. Forum 706–709, 1089 (2012).

B. Liu, Y. Liu, Y.P. Li, W. Zhang, and A. Chiba, Intermetallics 19, 1184 (2011).

D. Hu, C. Yang, A. Huang, M. Dixon, and U. Hecht, Intermetallics 23, 49–56 (2012).

A. Donchev, E. Richter, M. Schütze, and R. Yankov, Intermetallics 14, 1168 (2006).

Z.W. Huang and D.G. Zhu, Intermetallics 16, 156 (2008).

W.F. Cui, C.M. Liu, V. Bauer, and H.J. Christ, Intermetallics 15, 675 (2007).

V. Bauer and H.J. Christ, Intermetallics 17, 370 (2009).

D. Hu, Intermetallics 10, 851 (2002).

Tazuddin, K. Biswas, and N.P. Gurao, Mater. Sci. Eng. A 657, 224 (2016).

J. Liu, Q.D. Luan, X.G. Wang, and L.M. Peng, Mater. Sci. Eng., A 527, 7658 (2010).

U. Hecht, V. Witusiewicz, A. Drevermann, and J. Zollinger, Intermetallics 16, 969 (2008).

S. Roy, A. Sarkar, and S. Suwas, Mater. Sci. Eng., A 528, 449 (2010).

S. Roy, S. Suwas, S. Tamirisakandala, R. Srinivasan, and D. B. Miracle, TMS 2009 - 138th Annu. Meet. Exhib. Febr. 15, 2009 - Febr. 19, 2009 3, 63 (2009).

D. Hu, A.J. Huang, D. Novovic, and X. Wu, Intermetallics 14, 818 (2006).

H. Gabrisch, A. Stark, F.P. Schimansky, L. Wang, N. Schell, U. Lorenz, and F. Pyczak, Intermetallics 33, 44 (2013).

E. Schwaighofer, B. Rashkova, H. Clemens, A. Stark, and S. Mayer, Intermetallics 46, 173 (2014).

C. Scheu, E. Stergar, M. Schober, L. Cha, H. Clemens, A. Bartels, F.P. Schimansky, and A. Cerezo, Acta Mater. 57, 1504 (2009).

D. Daloz, U. Hecht, J. Zollinger, H. Combeau, A. Hazotte, and M. Založnik, Intermetallics 19, 749 (2011).

J. Barbosa, C.S. Ribeiro, and A.C. Monteiro, Intermetallics 15, 945 (2007).

S. Bolz, M. Oehring, J. Lindemann, F. Pyczak, J. Paul, A. Stark, T. Lippmann, S. Schrüfer, D. Roth-Fagaraseanu, A. Schreyer, and S. Weiß, Intermetallics 58, 71 (2015).

S.L. Semiatin, V. Seetharaman, and V.K. Jain, Metall. Mater. Trans. A 25, 2753 (1994).

F. Appel, M. Oehring, J.D.H. Paul, C. Klinkenberg, and T. Carneiro, Intermetallics 12, 791 (2004).

V. Seetharaman and S.L. Semiatin, Metall. Mater. Trans. A 28, 2309 (1997).

T. Klein, B. Rashkova, D. Holec, H. Clemens, and S. Mayer, Acta Mater. 110, 236 (2016).

P. Erdely, R. Werner, E. Schwaighofer, H. Clemens, and S. Mayer, Intermetallics 57, 17 (2015).

N. Prasad, N. Bibhanshu, N. Nayan, G.S. Avadhani, and S. Suwas, J. Mater. Res. 34, 744 (2019).

J. Beddoes, L. Zhao, J.-P. Immarigeon, and W. Wallace, Mater. Sci. Eng., A 183, 211 (1994).

R. Raj, Metall. Trans. A 12, 1089 (1981).

S.L. Semiatin, K.A. Lark, D.R. Barker, V. Seetharaman, and B. Marquardt, Metall. Trans. A 23, 295–305 (1992).

H. Jiang, F.A. Garcia-Pastor, D. Hu, X. Wu, M.H. Loretto, M. Preuss, and P.J. Withers, Acta Mater. 57, 1357 (2009).

Y. Li, L. Zhou, J. Lin, H. Chang, and F. Li, J. Alloys Compd. 668, 22 (2016).

S.Z. Zhang, F.T. Kong, Y.Y. Chen, Z.Y. Liu, and J.P. Lin, Intermetallics 31, 208 (2012).

D. Peter, G.B. Viswanathan, M.F.X. Wagner, and G. Eggeler, Mater. Sci. Eng., A 510–511, 359 (2009).

Y.J. Li, Q.M. Hu, D.S. Xu, and R. Yang, Intermetallics 19, 793 (2011).

F. Appel, J.D.H. Paul, and M. Oehring, Gamma Titanium Aluminide Alloys: Science and Technology (Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, 2014)

W. Schillinger, A. Bartels, R. Gerling, F.P. Schimansky, and H. Clemens, Intermetallics 14, 336 (2006).

Y. He, Z. Liu, G. Zhou, H. Wang, C. Bai, D. Rodney, F. Appel, D. Xu, and R. Yang, Scr. Mater. 143, 98 (2018).

P.B. Hirsch, Philos. Mag. 83, 1007 (2003).

L. Song, L. Wang, M. Oehring, X. Hu, F. Appel, U. Lorenz, F. Pyczak, and T. Zhang, Intermetallics 109, 91 (2019).

Y. He, Z. Liu, G. Zhou, H. Wang, C. Bai, D. Rodney, F. Appel, D. Xu, and R. Yang, Scr. Mater. 143, 98 (2018).

F. Appel, H. Clemens, and F.D. Fischer, Prog. Mater Sci. 81, 55 (2016).

R.V. Ramanujan, Int. Mater. Rev. 45, 217 (2000).

S. Suwas, R.K. Ray, A.K. Singh, and S. Bhargava, Acta Mater. 47, 4585 (1999).

S. Suwas and R.K. Ray, Acta Mater. 47, 4599 (1999).

L. Xiang, B. Tang, X. Xue, H. Kou, and J. Li, Intermetallics 97, 52 (2018).

R. Shi, H.L. Fraser, and Y.N. Wang, Acta Mater. 75, 156 (2014).

W.J. Zhang and S.C. Deevi, G. L. Chen 10, 403 (2002).

S. Suwas and R.K. Ray, Bull. Mater. Sci. 22, 581 (1999).

S. Suwas and R.K. Ray, Scr. Mater. 44, 275 (2001).

S. Roy and S. Suwas, J. Alloys Compd. 548, 110 (2013).

L. Xiang, B. Tang, X. Xue, H. Kou, and J. Li, Metals (Basel). 7, 261 (2017).

H. Liu, R. Rong, F. Gao, Y. Liu, Z. Li, and Q. Wang, J. Mater. Eng. Perform. 26, 3151 (2017).

N.D. Stepanov, D.G. Shaysultanov, N.Y. Yurchenko, S.V. Zherebtsov, A.N. Ladygin, G.A. Salishchev, and M.A. Tikhonovsky, Mater. Sci. Eng., A 636, 188 (2015).

Y. Zong, D. Wen, W. Xu, D. Yang, D. Shan, and Z. Liu, Procedia Eng. 81, 1420 (2014).

F. Chen and Z. Cui, TMS (The Miner (Proceeding: Met. Mater. Soc, 2016).

V. Seetharaman and S.L. Semiatin, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 33, 3817 (2002).

A.J. Palomares-Garcia, M.T. Perez-Prado, and J.M. Molina-Aldareguia, Acta Mater. 123, 102 (2017).

Acknowledgements

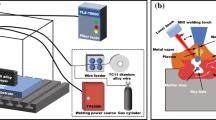

This work was carried out under the aegis of the GTMAP programme of Aeronautics Research and Development Board (AR&DB), Government of India. The funding provided by AR&DB is gratefully acknowledged. The authors thank Prof. Murugaiyan Amirthalingam of IIT Madras for providing the Gleeble facility. Special thanks to K. Rangan for his help in successfully carrying out all the deformation tests. The authors also acknowledge the help rendered by Dr. S. Banumathy of DMRL Hyderabad.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bibhanshu, N., Bhattacharjee, A. & Suwas, S. Influence of Temperature and Strain Rate on Microstructural Evolution During Hot Compression of Ti-45Al-xNb-0.2C-0.2B Titanium Aluminide Alloys. JOM 71, 3552–3564 (2019). https://doi.org/10.1007/s11837-019-03722-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03722-2