Abstract

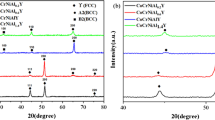

CoCrFeNiAlxTiy high-entropy alloys were produced by the induction melting method and their oxidation behavior investigated when exposed to 1000°C for different durations. One or more body-centered cubic phases were found in all alloys, except CoCrFeNiTi0.5. In the CoCrFeNiTi0.5 alloy, two different face-centered cubic phases and one tetragonal sigma phase were detected. Scanning electron microscopy elemental analysis showed that all the alloys exhibited homogeneous microstructure. Energy-dispersive x-ray spectroscopy analysis revealed that Cr and Fe elements were enriched in one phase and Al-Ni-Ti elements in another. The presence of Ti negatively affected the oxidation behavior. According to the oxidation test results, dominant Al2O3 formation was observed in the CoCrFeNiAl0.5 and CoCrFeNiAlTi0.5 alloys. As a result, these two alloys exhibited the best performance among the five high-entropy alloys in terms of mass gain and oxide thickness.

Similar content being viewed by others

References

J. Chen, X. Zhou, W. Wang, B. Liu, Y. Lv, W. Yang, D. Xu, and Y. Liu, J. Alloys Compd. 760, 15 (2018).

A. Kilmametov, R. Kulagin, A. Mazilkin, S. Seils, T. Boll, M. Heilmaier, and H. Hahn, Scr. Mater. 158, 29 (2019).

J.P. Couzinié and G. Dirras, Mater. Charact. 147, 533 (2018).

B. Carroll, Y. Gogotsi, A. Kovalchenko, A. Erdemir, and M.J. McNallan, Tribol. Lett. 15, 51 (2003).

H. Hadraba, Z. Chlup, A. Dlouhy, F. Dobes, P. Roupcova, M. Vilemova, and J. Matejicek, Mater. Sci. Eng. A 689, 252 (2017).

N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, S. Zherebtsov, A. Efimov, and G. Salishchev, Intermetallics 59, 8 (2015).

W. Kai, F.P. Cheng, C.Y. Liao, C.C. Li, R.T. Huang, and J.J. Kai, Mater. Chem. Phys. 210, 362 (2018).

J. Gild, M. Samiee, J.L. Braun, T. Harrington, H. Vega, P.E. Hopkins, K. Vecchio, and J. Luo, J. Eur. Ceram. Soc. 38, 3578 (2018).

Y.F. Kao, T.J. Chen, S.K. Chen, and J.W. Yeh, J. Alloys Compd. 488, 57 (2009).

Z. Wang, X. Wang, H. Yue, G. Shi, and S. Wang, Mater. Sci. Eng. A 627, 391 (2015).

A. Erdoğan, T. Yener, and S. Zeytin, Vacuum 155, 64 (2018).

R.X. Li, P.K. Liaw, and Y. Zhang, Mater. Sci. Eng. A 707, 668 (2017).

J. Jayaraj, P. Thirathipviwat, J. Han, and A. Gebert, Intermetallics 100, 9 (2018).

Z. Fu, W. Chen, Z. Chen, H. Wen, and E.J. Lavernia, Mater. Sci. Eng. A 619, 137 (2014).

Z.S. Nong, Y.N. Lei, and J.C. Zhu, Intermetallics 101, 144 (2018).

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Z. Fu, Intermetallics 56, 24 (2014).

N. Nayan, G. Singh, S.V.S.N. Murty, A.K. Jha, B. Pant, K.M. George, and U. Ramamurty, Intermetallics 55, 145 (2014).

Y. He, Y. Jiang, N. Xu, J. Zou, B. Huang, C.T. Liu, and P.K. Liaw, Adv. Mater. 19, 2102 (2007).

Z. Wang, P. Feng, X. Wang, P. Geng, F. Akhtar, and H. Zhang, Ceram. Int. 42, 12414 (2016).

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, S.W. Lee, and K. Niihara, J. Alloys Compd. 495, 33 (2010).

A. Erdoğan, M.S. Gök, and S. Zeytin, Friction (2019). https://doi.org/10.1007/s40544-019-0278-2.

M.H. Tsai and J.W. Yeh, Mater. Res. Lett. 2, 107 (2014).

A. Ayyagari, R. Salloom, S. Muskeri, and S. Mukherjee, Materialia 4, 99 (2018).

F. Tian, L.K. Varga, N. Chen, J. Shen, and L. Vitos, Intermetallics 58, 1 (2015).

Y.K. Kim, Y.A. Joo, H.S. Kim, and K.A. Lee, Intermetallics 98, 45 (2018).

F. Dobeš, H. Hadraba, Z. Chlup, A. Dlouhý, M. Vilémová, and J. Matějíček, Mater. Sci. Eng. A 732, 99 (2018).

S. Sheikh, M.K. Bijaksana, A. Motallebzadeh, S. Shafeie, A. Lozinko, L. Gan, T.K. Tsao, U. Klement, D. Canadinc, H. Murakami, and S. Guo, Intermetallics 97, 58 (2018).

S. Sheikh, L. Gan, T.K. Tsao, H. Murakami, S. Shafeie, and S. Guo, Intermetallics 103, 40 (2018).

W. Kai, C.C. Li, F.P. Cheng, K.P. Chu, R.T. Huang, L.W. Tsay, and J.J. Kai, Corros. Sci. 121, 116 (2017).

G. Laplanche, U.F. Volkert, G. Eggeler, and E.P. George, Oxid. Met. 85, 629 (2016).

T.M. Butler, J.P. Alfano, R.L. Martens, and M.L. Weaver, JOM 67, 246 (2015).

K.M. Doleker, Y. Ozgurluk, and A.C. Karaoglanli, Surf. Coat. Technol. 351, 78 (2018).

H.P. Chou, Y.S. Chang, S.K. Chen, and J.W. Yeh, Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 163, 184 (2009).

H. Zhang, Q.-T. Wang, Q.-H. Tang, and P.-Q. Dai, Corros. Prot. 34, 561 (2013).

P.Y. Hou and J. Stringer, Mater. Sci. Eng. A 202, 1 (1995).

H.T. Mallikarjuna, W.F. Caley, and N.L. Richards, J. Mater. Eng. Perform. 26, 4838 (2017).

N.A. Omran, A.M. Woo, K.D. Kim, D.K. Kim, S.W. Moon, M.S. Barakat, and D.L. Zhang, Met. Mater. Int. 14, 321 (2008).

A. Munitz, S. Salhov, S. Hayun, and N. Frage, J. Alloys Compd. 683, 221 (2016).

B.S. Murty, J.W. Yeh, and S. Ranganathan, High Entropy Alloy (Oxford: Butterworth-Heinemann, 2014), pp. 13–35.

A. Raphel, S. Kumaran, K.V. Kumar, and L. Varghese, Mater Today Proc. 4, 195 (2017).

M. Stygar, K. Berent, G. Cieślak, J. Dąbrowa, T. Kulik, K. Mroczka, and M. Danielewski, Intermetallics 84, 52 (2017).

V.K. Tolpygo and D.R. Clarke, Mater. High Temp. 17, 59 (2000).

J.L. Smialek and R. Gibala, Metall. Trans. A 14, 2143 (1983).

S. Wang, B.L. Shen, K. Zhang, Z. Chen, P. Zhang, and C.L. Chen, Vacuum 163, 263 (2019).

N. Birks, G.H. Meier, and F.S. Pettit, Introduction to the High-Temperature Oxidation of Metals, 2nd ed. (Cambridge: Cambridge University Press, 2006).

C.S. Giggins and F.S. Pettit, J. Electrochem. Soc. 118, 1782 (1971).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Erdogan, A., Doleker, K.M. & Zeytin, S. Effect of Al and Ti on High-Temperature Oxidation Behavior of CoCrFeNi-Based High-Entropy Alloys. JOM 71, 3499–3510 (2019). https://doi.org/10.1007/s11837-019-03679-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03679-2