Abstract

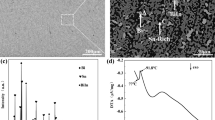

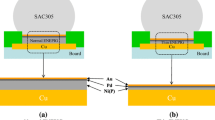

The lack of systematic evaluation on the feasibility of fabricating solderable coatings through a hot-dipped tinning process restricts the increasing applications of this process in the electronics industry. In this paper, the temperature-dependence, wettability, thermal stability, and microstructure of solderable Sn coatings produced by hot-dipped tinning are evaluated synthetically, which aims at developing a cost-efficient and environment-friendly way to fabricate solderable Sn coatings. Experimental results show that a dipping temperature of 280–320°C and dipping time of 4–6 s are appropriate process conditions for C1100 foils. The solderability of C1100 foils is superior to C194 foils. After long-term service (up to 500 h) at elevated temperature, sharp spines caused by SnO2 whiskers appear on the surface of coated C194 foils, which increase the risk of short circuit in use and lower their reliability. The addition of microalloying elements may be a possible solution to restrain SnO2 whiskers.

Similar content being viewed by others

References

M. Spitz, M. Fleischanderl, R. Sierlinger, M. Reischauerb, F. Perndorfer, and G. Fafilek, J. Mater. Process. Technol. 216, 339 (2015).

M.E. Makhatha, O.S. Fatoba, and E.T. Akinlabi, Int. J. Adv. Manuf. Technol. 94, 1 (2017).

H. Diao, C.Q. Wang, and L. Wang, Adv. Mater. Res. 32, 93 (2008).

R.A. Gagliano, G. Ghosh, and M.E. Fine, J. Electron. Mater. 31, 1195 (2002).

Z.H. Zhang, M.Y. Li, Z.Q. Liu, and S.H. Yang, Acta Mater. 104, 1 (2016).

I. Buresch, Proceeding of ICEC 2014—27th International Conference on Electrical Contacts (2014), p. 175.

M. Ohki, T. Ishibashi, and W. Suzuki, J. Mater. Test. Res. Assoc. Jpn. 54, 92 (2009).

J.F. Li, S.H. Mannan, M.P. Clode, D.C. Whalley, and D.A. Hutt, Acta Mater. 54, 2907 (2006).

M. Braunovic, Proceedings of the 49th IEEE Holm Conference on IEEE (2003), p. 124.

T.C. Chang, M.H. Hon, and M.C. Wang, J. Alloys Compd. 352, 168 (2003).

J. Mendala, Solid State Phenom. 246, 113 (2016).

Y.W. Park, G.N.K.R. Bapu, and Y.L. Kang, Appl. Surf. Sci. 255, 4434 (2009).

Q. Wang, Z. Peng, Y. Wang, and X. Fu, Ceram. Int. 44, 6894 (2018).

H. Asgari, M.R. Toroghinejad, and M.A. Golozar, J. Mater. Process. Technol. 198, 54 (2008).

K.H. Prakash and T. Sritharan, Acta Mater. 49, 2481 (2001).

I. Buresch, Vde Fachberichte 67, 38 (2011).

K.N. Tu and K. Zeng, Mater. Sci. Eng., R 38, 55 (2002).

C.M.L. Wu, D.Q. Yu, C.M.T. Law, and L. Wang, Mater. Sci. Eng., R 44, 1 (2004).

Y. Takaku, X.J. Liu, I. Ohnuma, R. Kainuma, and K. Ishida, Mater. Trans. 45, 646 (2004).

S.W. Tang, X.H. Cai, Z. He, H.Y. Shao, Z.J. Li, and E. Chen, Constr. Build. Mater. 113, 939 (2016).

S.W. Tang, H.G. Zhu, Z.J. Li, E. Chen, and H.Y. Shao, Constr. Build. Mater. 75, 11 (2015).

G. Montavon, C. Coddet, C.C. Berndt, and S.H. Leigh, J. Therm. Spray Technol. 7, 229 (1998).

N. Saunders and A.P. Miodownik, Binary Alloy Phase Diagrams (Materials Park: ASM International, 1990), pp. 1481–1483.

X.J. Liu, R. Kainuma, C.P. Wang, I. Ohnuma, and K. Ishida, Metall. Mater. Trans. A 35, 164 (2004).

Acknowledgements

The presented investigations have been supported by the Science and Technology Cooperation Open Project of Henan Province of China (Grant No. 172106000058) and the Joint Funds of National Natural Science Foundation of China (Grant No. U1704143). The authors kindly acknowledge these supports.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiang, N., Yin, T., Tian, Bh. et al. Evaluation on the Manufacturability of Solderable Sn Coatings Obtained by Employing Hot-Dipped Tinning Process. JOM 71, 4284–4295 (2019). https://doi.org/10.1007/s11837-019-03596-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03596-4