Abstract

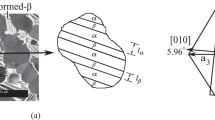

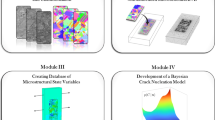

This paper develops a bottom-up and top-down multi-scale modeling framework for predicting fatigue crack nucleation in structures of titanium alloys, e.g., Ti-7Al. A parametrically homogenized constitutive model (PHCM) and a parametrically homogenized crack nucleation model (PHCNM) are developed from computational homogenization of crystal plasticity finite element simulation results performed on microstructural statistically equivalent RVEs. Bayesian inference and machine-learning methods are employed to derive microstructure-dependent functional forms of PHCM and PHCNM coefficients. The PHCM is augmented with uncertainty quantification to account for model reduction errors and microstructural uncertainty. Macroscopic finite element models for Ti-7Al test specimens are created by matching correlation functions of microtexture in electron back-scatter diffraction scans. Nucleation hot-spots are identified by PHCNM in macroscopic simulations of stress-controlled dwell loading, then top–down microscopic simulations are performed to probe into the crack nucleation process. The computed distributions of nucleation lives and locations follow experimentally observed characteristics of the dwell effect in Ti alloys.

Similar content being viewed by others

Abbreviations

- CPFE:

-

Crystal plasticity finite element

- EBSD:

-

Electron back-scatter diffraction

- ED/TD:

-

Extrusion and transverse directions

- MTR:

-

Micro-textured region

- PHCM:

-

Parametrically homogenized constitutive model

- PHCNM:

-

Parametrically homogenized crack nucleation model

- SERVE:

-

Statistically equivalent representative volume elements

- UQ/UP:

-

Uncertainty quantification/propagation

- WATMUS:

-

Wavelet-induced accelerated multi-timescale integration algorithm

- Y.S.:

-

Macroscopic yield strength

References

V. Sinha, J.E. Spowart, M.J. Mills, and J.C. Williams, Metall. Mater. Trans. A 37(5), 1507 (2006).

P.O. Tympel, T.C. Lindley, E.A. Saunders, M. Dixon, and D. Dye, in Proceedindgs of 13th World Conference on Titan (Wiley, Hoboken, NJ, 2016), pp. 985–991.

A.L. Pilchak, A. Hutson, W.J. Porter, D. Buchanan, and R. John, in Proceedings of 13th World Conference on Titan (Wiley, Hoboken, NJ, 2016), pp. 993–998.

D. Ozturk, A. Pilchak, and S. Ghosh, Scr. Mater. 127, 15 (2017).

W. Evans and M. Bache, Int. J. Fatigue 16(7), 443 (1994).

M.E. Kassner, Y. Kosaka, and J.S. Hall, Metall. Mater. Trans. A 30(9), 2383 (1999).

V. Doquet and V. De Greef, Int. J. Fatigue 38, 118 (2012).

V. Sinha, M.J. Mills, and J.C. Williams, Metall. Mater. Trans. A 37(6), 2015 (2006).

M. Anahid, M.K. Samal, and S. Ghosh, J. Mech. Phys. Solids 59(10), 2157 (2011).

V. Hasija, S. Ghosh, M.J. Mills, and D.S. Joseph, Acta Mater. 51(15), 4533 (2003).

J.C. Williams, R.G. Baggerly, and N.E. Paton, Metall. Mater. Trans. A 33(3), 837 (2002).

A.L. Pilchak and J.C. Williams, Metall. Mater. Trans. A 42(4), 1000 (2011).

M. Cuddihy, A. Stapleton, S. Williams, and F. Dunne, Int. J. Fatigue 97, 177 (2017).

X. Zhang, D.J. O’Brien, and S. Ghosh, Comput. Methods Appl. Mech. Eng. 346, 456 (2019).

S. Kotha, D. Ozturk, and S. Ghosh, Int. J. Plast. (2019). https://doi.org/10.1016/j.ijplas.2019.05.008

S. Kotha, D. Ozturk, and S. Ghosh, Int. J. Plast. (2019). https://doi.org/10.1016/j.ijplas.2019.05.007

D. Ozturk, A. Shahba, and S. Ghosh, Fatigue Fract. Eng. Mater. Struct. 39(6), 752 (2016).

A.L. Pilchak, Scr. Mater. 74, 68 (2014).

M.A. Groeber and M.A. Jackson, Integr. Mater. Manuf. Innov. 3(1), 5 (2014).

S. Swaminathan, S. Ghosh, and N.J. Pagano, J. Comp. Mater. 40(7), 583 (2006).

A. Bagri, G. Weber, J.C. Stinville, W. Lenthe, T. Pollock, C. Woodward, and S. Ghosh, Metall. Mater. Trans. A 49(11), 5727 (2018).

M. Pinz, G. Weber, W. Lenthe, M. Uchic, T. Pollock, and S. Ghosh, Acta Mater. 157, 245 (2018).

X. Tu, A. Shahba, J. Shen, and S. Ghosh, Int. J. Plast. 115, 268 (2019).

D. Ozturk, S. Kotha, A.L. Pilchak, and S. Ghosh, J. Mech. Phys. Solids 128, 181 (2019). https://doi.org/10.1016/j.jmps.2019.04.009.

D. Deka, D.S. Joseph, S. Ghosh, and M.J. Mills, Metall. Mater. Trans. A 37(5), 1371 (2006).

G. Venkatramani, S. Ghosh, and M. Mills, Acta Mater. 55(11), 3971 (2007).

D.C. Pagan, P.A. Shade, N.R. Barton, J.S. Park, P. Kenesei, D.B. Menasche, and J.V. Bernier, Acta Mater. 128, 406 (2017).

S. Ghosh and P. Chakraborty, Int. J. Fatigue 48, 231 (2013).

S. Keshavarz and S. Ghosh, Int. J. Solids Struct. 55, 17 (2015).

O. Cazacu, B. Plunkett, and F. Barlat, Int. J. Plast. 22(7), 1171 (2006).

A. Karafillis and M. Boyce, J. Mech. Phys. Solids 41(12), 1859 (1993).

M. Schmidt and H. Lipson, Science (80-. ). 324(5923), 81 (2009)

E. Voce, Metallurgica 51, 219 (1955).

S. ABAQUS/Standard, Dassault Systemes. Dassault systemes, simulia (2014). URL https://www.3ds.com/products-services/simulia/products/abaqus/.

D. Barber, in Bayesian Reasoning and Machine Learning (Cambridge: Cambridge University Press, 2012), pp. 392–411.

J.O. Berger, Statistical Decision Theory and Bayesian Analysis, 2nd edn. (New York: Springer, 1985).

L. Isserlis, Biometrika 12(1–2), 134 (1918).

D.S. Joseph, P. Chakraborty, and S. Ghosh, Comput. Methods Appl. Mech. Eng. 199(33–36), 2177 (2010).

L. Toubal, P. Bocher, and A. Moreau, Int. J. Fatigue 31(3), 601 (2009).

Acknowledgements

This work is supported through a subcontract to JHU (sub-recipient) from the Ohio State University (main recipient) through a sub-Award No. 60038238 from an AFRL Grant No. FA8650-13-2-2347 as a part of the AFRL Collaborative Center of Structural Sciences. The program managers of this grant are Dr. B. Smarslok and Dr. R. Chona, and the PI is Prof. J. McNamara. This support to JHU is gratefully acknowledged. Computer use of the Hopkins High Performance Computing facilities is gratefully acknowledged. Adam Pilchak gratefully acknowledges the support of AFOSR Task No. 12RX01COR, with program manager Dr. A. Sayir.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ozturk, D., Kotha, S., Pilchak, A.L. et al. Parametrically Homogenized Constitutive Models (PHCMs) for Multi-scale Predictions of Fatigue Crack Nucleation in Titanium Alloys. JOM 71, 2657–2670 (2019). https://doi.org/10.1007/s11837-019-03554-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03554-0