Abstract

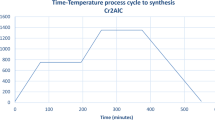

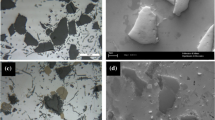

Cu/SiCP composites with high strength and high conductivity were prepared by in situ carbonization reaction of silicon. The Cu-Si powder and C powder were mechanically mixed, and in situ carbonized at 850°C for 48 h, then oxidation-treated in dry air atmosphere at 650°C for 8 h, followed by reduction-treating in hydrogen atmosphere at 500°C for 90 min. The results showed that some nano-scale and micron-scale SiCp particles as well as a small amount of nano-scale SiO2 formed during fabrication. The tensile strength, yield strength, elongation and conductivity of the hot-extruded composite were 279 MPa, 180 MPa, 22.80% and 91.48% IACS, respectively; and those of the composite treated by cold-rolling with a reduction of 80% and then annealing at 350°C for 30 min were 425 MPa, 403 MPa, 10.85% and 90.15% IACS, respectively.

Similar content being viewed by others

References

G.C. Efe, M. Ipek, S. Zeytin, and C. Bindal, Compos. Part B 43, 1813 (2012).

J. Sudagar, J. Lian, and W. Sha, J. Alloy. Compd. 44, 183 (2013).

J.T. Jiang, L. Zhen, C.Y. Xu, and X.L. Wu, Surf. Coat. Tech. 201, 3139 (2006).

S. Liang, L. Xu, L. Fang, and Z. Fan, Powder Metall. Tech. 21, 201 (2003).

M.S. Motta, P.K. Jena, E.A. Brocchi, and I.G. Solórzano, Mater. Sci. Eng., C 15, 175 (2001).

Z. Zhang and X.U. Shaofan, Chin. J. Rare. Met. 26, 359 (2007).

P. Gonon and F. El Kamel, J. Appl. Phys. 101, 1414 (2007).

F. Shojaeepour, P. Abachi, and K. Purazrang, Powder Technol. 222, 80 (2012).

G.C. Efe, S. Zeytin, and C. Bindal, Mater. Des. 36, 633 (2012).

M. Barmouz, P. Asadi, M.K.B. Givi, and M. Taherishargh, Mater. Sci. Eng., A 528, 1740 (2011).

K.M. Shu and G.C. Tu, Int. J. Mach. Tools Manuf. 43, 845 (2003).

R. Treichler, T. Weissgaerber, and T. Kiendl, Appl. Surf. Sci. 252, 7086 (2006).

N.B. Khosroshahi, R.A. Khosroshahi, R.T. Mousavian, and D. Brabazon, Surf. Eng. 30, 747 (2014).

H. Ming, Y. Zhang, L. Tang, S. Lin, and G. Jing, Appl. Surf. Sci. 332, 720 (2015).

M.R. Akbarpour, E. Salahi, F.A. Hesari, E.Y. Yoon, H.S. Kim, and A. Simchi, Mater. Sci. Eng., A 68, 33 (2013).

M.S. Motta, P.K. Jena, E.A. Brocchi, and I.G. Solórzano, Mater. Sci. Eng., C 15, 175 (2001).

S.J. Han, J. Seo, K.H. Choe, and M.H. Kim, Met. Mater. Inter. 21, 270 (2015).

M.R. Akbarpour and S. Alipour, Ceram. Int. 43, 13364 (2017).

H.K. Kang, Surf. Coat. Tech. 190, 448 (2005).

N.R. Tao, Z.B. Wang, and W.P. Tong, Acta Mater. 50, 4603 (2002).

M. Mabuchi, Acta Mater. 44, 4611 (1996).

J. Lee, J.Y. Jung, and E.S. Lee, Mater. Sci. Eng., A 277, 274 (2000).

Y.J. Zhou, K.X. Song, and J.D. Xing, J. Alloys Compd. 658, 920 (2016).

Z.Q. Zheng, Fundamentals of Materials Science (Changsa: Central South University Press, 2005).

B. Lengeler, W. Schilling, and H. Wenzl, J. Low Tempe Phys. 2, 237 (1970).

Y. Li, Z. Xiao, Z. Li, Z. Zhou, Z. Yang, and Q. Lei, J. Alloy. Compd. 723, 1162 (2017).

Acknowledgements

The authors acknowledge the financial support by the National key R & D program of China (Grant No. 2016YFB0301301), National Natural Science Foundation of China (Grant Nos. U1637210 & 51601227), Natural Science Foundation of Hunan Province (Grant No. 2018JJ3650), and the Project of State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiang, T., Dai, J., Qiu, W. et al. Cu/SiCP Composites Prepared by In-Situ Carbonization Synthesis. JOM 71, 2513–2521 (2019). https://doi.org/10.1007/s11837-019-03483-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03483-y