Abstract

Nanocrystalline metals typically have high fatigue strengths but low resistance to crack propagation. Amorphous intergranular films are disordered grain boundary complexions that have been shown to delay crack nucleation and slow crack propagation during monotonic loading by diffusing grain boundary strain concentrations, which suggests they may also be beneficial for fatigue properties. To probe this hypothesis, in situ transmission electron microscopy fatigue cycling is performed on Cu-1 at.% Zr thin films thermally treated to have either only ordered grain boundaries or amorphous intergranular films. The sample with only ordered grain boundaries experienced grain coarsening at crack initiation followed by unsteady crack propagation and extensive nanocracking, whereas the sample containing amorphous intergranular films had no grain coarsening at crack initiation followed by steady crack propagation and distributed plastic activity. Microstructural design for control of these behaviors through simple thermal treatments can allow for the improvement of nanocrystalline metal fatigue toughness.

Similar content being viewed by others

References

K.M. Youssef, R.O. Scattergood, K.L. Murty, J.A. Horton, and C.C. Koch, Appl. Phys. Lett. 87, 091904 (2005).

C.C. Koch, K.M. Youssef, R.O. Scattergood, and K.L. Murty, Adv. Eng. Mater. 7, 787 (2005).

T.J. Rupert and C.A. Schuh, Acta Mater. 58, 4137 (2010).

R.O. Ritchie, Int. J. Fracture 100, 55 (1999).

T. Hanlon, E.D. Tabachnikova, and S. Suresh, Int. J. Fatigue 27, 1147 (2005).

T. Hanlon, Y.N. Kwon, and S. Suresh, Scr. Mater. 49, 675 (2003).

T.A. Furnish, D.C. Bufford, F. Ren, A. Mehta, K. Hattar, and B.L. Boyce, Scr. Mater. 143, 15 (2018).

T.A. Furnish, A. Mehta, D. Van Campen, D.C. Bufford, K. Hattar, and B.L. Boyce, J. Mater. Sci. 52, 46 (2017).

R.A. Meirom, D.H. Alsem, A.L. Romasco, T. Clark, R.G. Polcawich, J.S. Pulskamp, M. Dubey, R.O. Ritchie, and C.L. Muhlstein, Acta Mater. 59, 1141 (2011).

M.D. Sangid, Int. J. Fatigue 57, 58 (2013).

H.A. Padilla and B.L. Boyce, Exp. Mech. 50, 5 (2010).

K.S. Kumar, H. Van Swygenhoven, and S. Suresh, Acta Mater. 51, 5743 (2003).

F. Mompiou, M. Legros, A. Boé, M. Coulombier, J.P. Raskin, and T. Pardoen, Acta Mater. 61, 205 (2013).

K.S. Kumar, S. Suresh, M.F. Chisholm, J.A. Horton, and P. Wang, Acta Mater. 51, 387 (2003).

D. Gianola, B. Mendis, X. Cheng, and K. Hemker, Mater. Sci. Eng. A 483, 637 (2008).

L. Wang, T. Xin, D. Kong, X. Shu, Y. Chen, H. Zhou, J. Teng, Z. Zhang, J. Zou, and X.D. Han, Scr. Mater. 134, 95 (2017).

Z.X. Wu, Y.W. Zhang, M.H. Jhon, and D.J. Srolovitz, Acta Mater. 61, 5807 (2013).

P. Liu, S.C. Mao, L.H. Wang, X.D. Han, and Z. Zhang, Scr. Mater. 64, 343 (2011).

S.J. Dillon, M. Tang, W.C. Carter, and M.P. Harmer, Acta Mater. 55, 6208 (2007).

G. Palumbo, S.J. Thorpe, and K.T. Aust, Scr. Met. Mater. 24, 1347 (1990).

A. Khalajhedayati, Z. Pan, and T.J. Rupert, Nat. Commun. 7, 10802 (2016).

Z. Pan and T.J. Rupert, Acta Mater. 89, 205 (2015).

A. Khalajhedayati and T.J. Rupert, JOM 67, 2788 (2015).

L.F. Allard, W.C. Bigelow, M. Jose-Yacaman, D.P. Nackashi, J. Damiano, and S.E. Mick, Microsc. Res. Tech. 72, 208 (2009).

L. Zhong, J. Wang, H. Sheng, Z. Zhang, and S.X. Mao, Nature 512, 177 (2014).

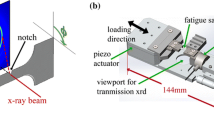

D.C. Bufford, D. Stauffer, W.M. Mook, S.A. Syed Asif, B.L. Boyce, and K. Hattar, Nano Lett. 16, 4946 (2016).

X.K. Zhu, Intl. J. Press. Vess. Pip. 156, 40 (2017).

V. Samaeeaghmiyoni, H. Idrissi, J. Groten, R. Schwaiger, and D. Schryvers, Micron 94, 66 (2017).

K. Hattar, D.C. Bufford, and D.L. Buller, Nucl. Instrum. Methods Phys. Res. Sect. B 338, 56 (2014).

S.K. Lin, Y.L. Lee, and M.W. Lu, Int. J. Fatigue 23, 75 (2001).

R.C. Hugo, H. Kung, J.R. Weertman, R. Mitra, J.A. Knapp, and D.M. Follstaedt, Acta Mater. 51, 1937 (2003).

C.M. Park and J.A. Bain, J. Appl. Phys. 91, 6830 (2002).

J.D. Schuler and T.J. Rupert, Acta Mater. 140, 196 (2017).

Q. Jin, D.S. Wilkinson, and G.C. Weatherly, J. Eur. Ceram. Soc. 18, 2281 (1998).

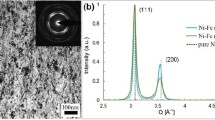

J.D. Schuler, O.K. Donaldson, and T.J. Rupert, Scr. Mater. 154, 49 (2018).

C.V. Thompson, Annu. Rev. Mater. Sci. 20, 245 (1990).

Y. Yang, B. Imasogie, G.J. Fan, P.K. Liaw, and W.O. Soboyejo, Metall. Mater. Trans. A 39, 1145 (2008).

D. Farkas, M. Willemann, and B. Hyde, Phys. Rev. Lett. 94, 165502 (2005).

R.O. Ritchie, Mater. Sci. Eng., A 103, 15 (1988).

J.K. Shang and R.O. Ritchie, Metall. Trans. A 20, 897 (1989).

R. Ramachandramoorthy, R. Bernal, and H.D. Espinosa, ACS Nano 9, 4675 (2015).

Z. Liu, D. Yu, J. Tang, X. Chen, and X. Wang, Int. J. Press. Vess. Pip. 168, 11 (2018).

M.D. Thouless, J. Am. Ceram. Soc. 71, 408 (1988).

A. Vinogradov, J. Mater. Sci. 42, 1797 (2007).

R. Pippan and A. Hohenwarter, Fatigue Fract. Eng. Mater. Struct. 40, 471 (2017).

C. Laird and G. Smith, Philos. Mag. 7, 847 (1962).

J. Xie, X. Wu, and Y. Hong, Scr. Mater. 57, 5 (2007).

K. Tanaka, Y. Nakai, and M. Yamashita, Int. J. Fracture 17, 519 (1981).

C. Bjerkén and S. Melin, Eng. Frac. Mech. 71, 2215 (2004).

M.Y. Gutkin and I. Ovid’ko, Philos. Mag. Lett. 84, 655 (2004).

S. Suresh, Metall. Trans. A 14, 2375 (1983).

A.M. Gokhale, W.J. Drury, and S. Mishra, in Fractography of Modern Engineering Materials: Composites and Metals, ed. J.E. Masters and L.N. Gilbertson (Philadelphia, PA: ASTM, 1993), p. 3.

D. Farkas, H. Van Swygenhoven, and P. Derlet, Phys. Rev. B Condens. Matter 66, 060101 (2002).

M.D. Sangid, G.J. Pataky, H. Sehitoglu, R.G. Rateick, T. Niendorf, and H.J. Maier, Acta Mater. 59, 7340 (2011).

Y. Zhang, G.J. Tucker, and J.R. Trelewicz, Acta Mater. 131, 39 (2017).

R. Liu, Y. Tian, Z. Zhang, X. An, P. Zhang, and Z. Zhang, Sci. Rep. 6, 27433 (2016).

G.Q. Xu and M.J. Demkowicz, Phys. Rev. Lett. 111, 145501 (2013).

T. Leitner, A. Hohenwarter, and R. Pippan, Mater. Sci. Eng. A 646, 294 (2015).

T.R. Bieler, P. Eisenlohr, F. Roters, D. Kumar, D.E. Mason, M.A. Crimp, and D. Raabe, Int. J. Plast 25, 1655 (2009).

A. Singh, L. Tang, M. Dao, L. Lu, and S. Suresh, Acta Mater. 59, 2437 (2011).

L. Liu, J. Wang, S.K. Gong, and S.X. Mao, Sci. Rep. 4, 4397 (2014).

V. Turlo and T.J. Rupert, Acta Mater. 151, 100 (2018).

Acknowledgements

JDS and TJR were supported by the U.S. Department of Energy, Office of Basic Energy Sciences, Materials Science and Engineering Division under Award DE-SC0014232, and the U.S. Department of Energy, Office of Science, Office of Workforce Development for Teachers and Scientists, Office of Science Graduate Student Research (SCGSR) program. BLB, KH, CMB, and NMH were supported by the U.S. Department of Energy, Office of Basic Energy Sciences, Materials Science and Engineering Division, under FWP 18-013170. The SCGSR program is administered by the Oak Ridge Institute for Science and Education for the DOE under Contract DE-SC0014664. TEM work was performed at the UC Irvine Materials Research Institute (IMRI). SEM and FIB work was performed at the UC Irvine Materials Research Institute (IMRI) using instrumentation funded in part by the National Science Foundation Center for Chemistry at the Space-Time Limit (CHE-0802913). Additional FIB and TEM work was performed at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science. Sandia National Laboratories is a multimission laboratory managed and operated by National Technology and Engineering Solutions of Sandia, LLC, a wholly owned subsidiary of Honeywell International, Inc., for the U.S. DOE’s National Nuclear Security Administration under Contract DE-NA-0003525. The views expressed in the article do not necessarily represent the views of the U.S. Department of Energy or of the U.S. government.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Schuler, J.D., Barr, C.M., Heckman, N.M. et al. In Situ High-Cycle Fatigue Reveals Importance of Grain Boundary Structure in Nanocrystalline Cu-Zr. JOM 71, 1221–1232 (2019). https://doi.org/10.1007/s11837-019-03361-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03361-7