Abstract

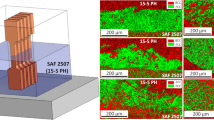

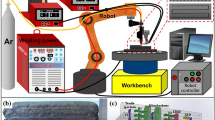

In this work, 3D plasma-metal deposition (3DPMD) is introduced as an innovative additive manufacturing process for multi-material components. The possibility of the production of multi-material parts in a layer-by-layer design with 3DPMD was investigated. Multi-material demonstrators with a continuous transition from the super duplex steel 1.4410 to the austenitic steel 1.4404 have been prepared and investigated. By analyzing the hardness, ferrite content, mechanical-technological properties and microstructure, it was shown that the production of multi-material components using 3DPMD is possible. The properties of the transition zone lie between those of the two pure metals. The evaluation of stress–strain curves showed that the strength of the transition zone is higher than that of the austenitic material. It can be concluded that the production of graded steel structures between 1.4404 and 1.4410 using 3DPMD is possible, and mixing of the materials in the transition zone does not weaken the component. The 3DPMD process is suitable to produce functionally graded multi-material components out of metal powders.

Similar content being viewed by others

Change history

08 March 2019

Gökhan Ertugrul’s name was misspelled on the original publication of this article. It appears correctly here.

References

A. Bandyopadhyay, B.V. Krishna, W. Xue, and S. Bose, J. Mater. Sci. Mater. Med. 20, 29 (2009).

J. Parthasarathy*, B. Starly, and S. Raman, J. Manuf. Process. 13, 160 (2011).

L.E. Murr, S.M. Gaytan, E. Martinez, F. Medina, and R.B. Wicker, Int. J. Biomater. 28, 1–14 (2012).

S. Sampath, H. Herman, N. Shimoda, and T. Saito, MRS Bull. 20, 27 (1995).

S. Suresh, A.E. Giannakopoulos, and J. Alcalá, Acta Mater. 45, 1307 (1997).

A.E. Giannakopoulos and S. Suresh, Int. J. Solids Struct. 34, 2393 (1997).

A.E. Giannakopoulos, S. Suresh, M. Finot, and M. Olsson, Acta Metall. Mater. 43, 1335 (1995).

R.L. Williamson, B.H. Rabin, and J.T. Drake, J. Appl. Phys. 74, 1310 (1993).

J.T. Drake, R.L. Williamson, and B.H. Rabin, J. Appl. Phys. 74, 1321 (1993).

F. Erdogan, Compos. Eng. 5, 753 (1995).

I. Yadroitsev, L. Thivillon, Ph. Bertrand, and I. Smurov, Appl. Surf. Sci. 254, 980 (2007).

R.M. Mirandaa, T.G. Santosa, J. Gandrab, N. Lopesa, and R.J.C. Silva, J. Mater. Process. Technol. 213, 1609 (2013).

H. Zou, H. Zhang, W. Guilan, and J. Li, in Electromagnetics Research Symposium (Moskau), 1953 (2009).

K. Höfer, A. Hälsig, and P. Mayr, Weld World (2018). https://doi.org/10.1007/s40194-017-0527-9.

K. Höfer, C. Teichgräber, P. Mayr, M. Berger, FüMoTeC 2, 1 (2017), ISBN 978-3-96100-034-0.

K. Höfer, A. Hälsig, P. Mayr, DVS Bericht, 337, 297 (2017), ISBN: 978-3-96144-008-5.

G. Posch, K. Chladil, and H. Chladil, Weld World 61, 873 (2017).

S. Cheruvathur, E.A. Lass, and C.E. Campbell, JOM 68, 930 (2016).

W. Hofmeister and M. Griffith, JOM 53, 30 (2001).

L. Jiapeng, J. Xiao, G. Ruinan, P. Zhou, Y. Huang, J. Sun, and M. Yan, Metals 8, 548 (2018).

Stahlschlüssel, Version 8.0, Edition 24 (2016).

D.J. Kotecki and T.A. Siewert, Weld J 5, 171 (1992).

DIN EN 10088-2 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hoefer, K., Nitsche, A., Abstoss, K.G. et al. Multi-material Additive Manufacturing by 3D Plasma Metal Deposition for Graded Structures of Super Duplex Alloy 1.4410 and the Austenitic Corrosion Resistant Alloy 1.4404. JOM 71, 1554–1559 (2019). https://doi.org/10.1007/s11837-019-03356-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03356-4