Abstract

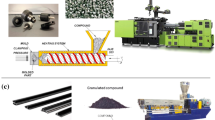

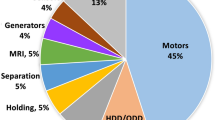

Additive manufacturing techniques for fabricating bonded magnets have the potential to reduce manufacturing cost and time-to-market of products and address the criticality of rare-earth elements (REEs), which is a concern for economic design of dependent applications such as permanent magnet machines. We investigated the magnetic alignment of anisotropic bonded magnet material comprising 65 vol.% Nd-Fe-B in nylon-12 produced by extrusion in a 20-W brushless direct current surface permanent magnet motor for submersible water pump application using finite element analysis. The results predict that sufficient alignment for this application could be obtained at low alignment fields (μ0H ≤ 1 T) with a reduction in the volume of critical materials by up to 40% compared with isotropic permanent magnets. This demonstrates the economic feasibility of incorporating a magnetic alignment field source into additive manufacturing systems for bonded magnets, and the potential of aligned anisotropic bonded magnets to address REE criticality.

Similar content being viewed by others

References

G.-C. Lee and T.-U. Jung, 2012 IEEE Vehicle Power and Propulsion Conference (Seoul, South Korea, 2012), pp. 48–50.

S. Sashidhar and B.G. Fernandes, IEEE Trans. Ind. Electron. 64, 104 (2016).

S. Sashidhar and B.G. Fernandes, 2015 IEEE International Conference on Industrial Technology (ICIT) (Seville, Spain, 2015), pp. 671–676.

S.F. Rabbi, M.A. Rahman, and S. Butt, 2014 Oceans—St. John’s (St. John’s, Canada, 2014) pp. 260–264.

Rep. No. DOE/PI-0009, U.S. Department of Energy, Oak Ridge, TN, January 2011.

K.V. Wong and A. Hernandez, ISRN Mech. Eng. 2012, 1 (2012).

I. Campbell, D. Bourell, and I. Gibson, Rapid Prototyp. J. 18, 255 (2012).

L. Li, A. Tirado, I.C. Nlebedim, O. Rios, B. Post, V. Kunc, R.R. Lowden, E. Lara-curzio, R. Fredette, J. Ormerod, T.A. Lograsso, and M.P. Paranthaman, Sci. Rep. 6, 1 (2016).

L. Li, B. Post, V. Kunc, A.M. Elliott, and M.P. Paranthaman, Scr. Mater. 135, 100 (2017).

C. Huber, C. Abert, F. Bruckner, M. Groenefeld, O. Muthsam, S. Schuschnigg, C. Vogler, R. Windl, and D. Suess, Appl. Phys. Lett. 109, 162401 (2016).

L. Li, K. Jones, B. Sales, J.L. Pries, I.C. Nlebedim, K. Jin, H. Bei, B.K. Post, M.S. Kesler, O. Rios, V. Kunc, R. Fredette, J. Ormerod, A. Williams, T.A. Lograsso, and M.P. Paranthaman, Addit. Manuf. 21, 495 (2018).

B.G. Compton, J.W. Kemp, T.V. Novikov, R.C. Pack, C.I. Nlebedim, C.E. Duty, O. Rios, and M.P. Paranthaman, Mater. Manuf. Process. 33, 109 (2016).

L. Li, A. Tirado, B.S. Conner, M. Chi, A.M. Elliott, O. Rios, H. Zhou, and M.P. Paranthaman, J. Magn. Magn. Mater. 438, 163 (2017).

M.P. Paranthaman, C.S. Shafer, A.M. Elliott, D.H. Siddel, M.A. McGuire, R.M. Springfield, J. Martin, R. Fredette, and J. Ormerod, JOM 68, 1978 (2016).

J.-M. Lamarre, F. Bernier, Int. Forum Magn. Appl. Technol. Mater. (MAGNETICS 2018), Orlando, (2018). http://magneticsconference.com/schedule/magnetic-materials-fabricated-by-cold-spray-additive-manufacturing/. Accessed 18 June 2018.

J. Ormerod and S. Constantinides, J. Appl. Phys. 81, 4816 (1997).

D. Brown, B.-M. Ma, and Z. Chen, J. Magn. Magn. Mater. 248, 432 (2002).

B.M. Ma, J.W. Herchenroeder, B. Smith, M. Suda, D.N. Brown, and Z. Chen, J. Magn. Magn. Mater. 239, 418 (2002).

J. Jacimovic, F. Binda, L.G. Herrmann, F. Greuter, J. Genta, M. Calvo, T. Tomse, and R.A. Simon, Adv. Eng. Mater. 19, 1700098 (2017).

F. Meng, R.P. Chaudhary, K. Gandha, I.C. Nlebedim, A. Palasyuk, E. Simsek, M.J. Kramer, and R.T. Ott, JOM 70, 872 (2018).

H. Mitarai, K. Noguchi, C. Mishima, H. Matsuoka, M. Yamazaki, and Y. Kawasugi, IEEE Trans. Magn. 50, 10 (2014).

I.C. Nlebedim, H. Ucar, C.B. Hatter, R.W. McCallum, S.K. McCall, M.J. Kramer, and M.P. Paranthaman, J. Magn. Magn. Mater. 422, 168 (2017).

H.A. Khazdozian, H. Ucar, C.B. Hatter, M.J. Kramer, M.P. Paranthaman, and I.C. Nlebedim, 3rd Pan American Materials Congress: Materials for Green Energy (San Diego, USA, 2017).

Aichi Steel Corporation, “Magfine NdFeB Anisotropic Resin-Bonded Magnet: Magfine Technical Datasheet (2015). https://www.aichi-steel.co.jp/ENGLISH/products/electromagnetic/bonded_magnet/item/magfine_datasheet-201705.pdf. Accessed 18 June 2018.

K. Gandha, L. Li, I.C. Nlebedim, B.K. Post, V. Kunc, B.C. Sales, J. Bell, and M.P. Paranthaman, J. Magn. Magn. Mater. 467, 8 (2018).

H. Hembach, S.A. Evans, and D. Gerling, 2008 18th International Conference on Electrical Machines (Vilamoura, Portugal, 2008), pp. 1–5.

R. Abdelmoula, N.B. Hadj, M. Chaieb, and R. Neji, J. Electr. Syst. 13, 528 (2017).

R. Islam, I. Husain, A. Fardoun, and K. McLaughlin, IEEE Trans. Ind. Appl. 45, 152 (2009).

M.Z. Youssef, IEEE Trans. Ind. Electron. 62, 3277 (2015).

Acknowledgements

This research was supported by the Critical Materials Institute, an Energy Innovation Hub funded by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office. Work was performed at Ames Laboratory, ORNL, and LLNL under Contracts DE-AC02-07CH11358, DE-AC05-00OR22725, and DE-AC52-07NA27344, respectively. The authors would like to thank James Bell for providing the magnetic material.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors have no competing financial interests.

Additional information

This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khazdozian, H.A., Li, L., Paranthaman, M.P. et al. Low-Field Alignment of Anisotropic Bonded Magnets for Additive Manufacturing of Permanent Magnet Motors. JOM 71, 626–632 (2019). https://doi.org/10.1007/s11837-018-3242-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3242-0