Abstract

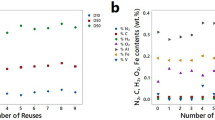

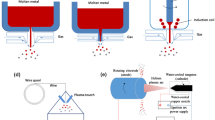

Cost control and quality of additive manufactured (AM) components are critical characteristics for the success of this technology for industrial applications. Understanding how the virgin powder changes in terms of chemistry and physical properties with reuse cycles provides important information that can be translated into cost-effective practices for managing recycled powder. In this study, we focused on an industrial AM setting, where different numbers of components were printed on each build. A single lot of powder was reused for manufacturing a total of 31 builds using a selective laser melting additive system. The effects of reuse cycles on the characteristics of Ti-6Al-4V extra low interstitial powder were evaluated, during and prior to the printing process, by means of particle size distribution, tap density, flowability, powder morphology, and chemical composition. Additionally, chemical analysis and tensile testing of solid bars in the hot isostatically pressed (HIP) condition were evaluated in relation to powder reuse times. After reusing the powder for 31 times, it was found that the oxygen content increased to a maximum of 0.13 wt.%, whereas nitrogen, aluminum, and vanadium remained stable. The powder exhibited surface coarsening, and although some elongated/irregular particles were observed, mostly spherical powder particles with fewer satellites were present. Flowability improved, and tap density showed a slight decline with reuse times. No detrimental effect was found on the tensile properties of solid material postprocessed using HIP.

Similar content being viewed by others

References

D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann, Acta Mater. 117, 371 (2016).

B.V. Hooreweder, Y. Apers, K. Lietaert, and J.-P. Kruth, Acta Biomater. 47, 193 (2017).

A.B. Nover, S.L. Lee, M.S. Georgescu, D.R. Howard, R.A. Saunders, W.T. Yu, R.W. Klein, A.P. Napolitano, G.A. Ateshian, and C.T. Hung, Acta Biomater. 27, 286 (2015).

Y. Wang, Y. Shen, Z. Wang, J. Yang, N. Liu, and W. Huang, Mater. Lett. 64, 674 (2010).

L.C. Ardila, F. Garciandia, J.B. González-Díaz, P. Álvarez, A. Echeverria, M.M. Petite, R. Deffley, and J. Ochoa, Phys. Procedia 56, 99 (2014).

V. Seyda, N. Kaufmann, and C. Emmelmann, Phys. Procedia 39, 425 (2012).

H.P. Tang, M. Qian, N. Liu, X.Z. Zhang, G.Y. Yang, and J. Wang, JOM 67, 555 (2015).

S.M. Gaytan, L.E. Murr, F. Medina, E. Martinez, M.I. Lopez, and R.B. Wicker, Mater. Technol. 24, 180 (2009).

K. Thejane, S. Chikosha, and W.B. du Preez, S. Afr. J. Ind. Eng. 18, 161 (2017).

M.T. Andani, R. Dehghani, M.R. Karamooz-Ravari, R. Mirzaeifar, and J. Ni, Addit. Manuf. 20, 33 (2018).

ASTM E1409-13, Standard Test Method for Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by Inert Gas Fusion (West Conshohocken: ASTM International, 2013).

ASTM E2371-13, Standard Test Method for Analysis of Titanium and Titanium Alloys by Direct Current Plasma and Inductively Coupled Plasma Atomic Emission Spectrometry (Performance-Based Test Methodology) (West Conshohocken: ASTM International, 2013).

ASTM B822-17, Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by Light Scattering (West Conshohocken: ASTM International, 2017).

ASTM B213-17, Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel (West Conshohocken: ASTM International, 2017).

ASTM B527–15, Standard Test Method for Tap Density of Metal Powders and Compounds (West Conshohocken: ASTM International, 2015).

ASTM F3001–14, Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4Vanadium ELI (Extra Low Interstitial) with Powder Bed Fusion (West Conshohocken: ASTM International, 2014).

M. Barclift, S. Joshi, T. Simpson, and C. Dickman, in Solid Freedom Fabrication Symposium, 2007 (2016).

J.A. Slotwinski and E.J. Garboczi, JOM 67, 538 (2015).

Y. Sun, M. Aindow, and R.J. Hebert, Addit. Manuf. 21, 544 (2018).

O.A. Quintana and W. Tong, JOM 69, 2693 (2017).

M. Yan, M.S. Dargusch, T. Ebel, and M. Qian, Acta Mater. 68, 196 (2014).

J.M. Oh, B.G. Lee, S.W. Cho, S.W. Lee, G.S. Choi, and J.W. Lim, Met. Mater. Int. 17, 733 (2011).

Acknowledgements

The authors would like to thank Andrew Rosenberger for the technical discussions throughout this investigation and Robert Rybolt for his technical assistance. We also thank Fionnan Mc Namara, Greg Duggan, and Eoin Hinchy for their valuable comments and suggestions on the planning of this study. Finally, we thank Todd Render for all the support provided throughout this study. All with DePuy Synthes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quintana, O.A., Alvarez, J., Mcmillan, R. et al. Effects of Reusing Ti-6Al-4V Powder in a Selective Laser Melting Additive System Operated in an Industrial Setting. JOM 70, 1863–1869 (2018). https://doi.org/10.1007/s11837-018-3011-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3011-0