Abstract

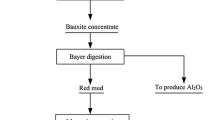

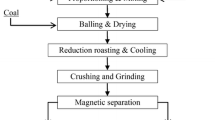

A technical route has been proposed to upgrade diasporic bauxite ores for iron and alumina enrichment based on reductive roasting, followed by magnetic separation and alkaline leaching. The thermodynamic analysis revealed that by reductive roasting of the bauxite ore at 980–1100°C, hematite in the ore is transformed to magnetite and kaolinite is converted into γ-Al2O3 and SiO2 (amorphous). Meanwhile, the diaspore changes to α-Al2O3, which favors the recovery of alumina via the Bayer process. The experimental results showed that, after reductive roasting and magnetic separation, iron and alumina in the bauxite ores could be effectively separated into magnetic and non-magnetic fractions, respectively. The iron was enriched in the magnetic fraction as iron concentrate with iron content of 60.15 wt.% and iron recovery of 42.89% after reductive roasting of the bauxite ore at 1000°C for 20 min in 10 vol.% CO/(CO + CO2) atmosphere, followed by magnetic separation at magnetic field intensity of 0.1 T. After desilication of the non-magnetic fraction, which was obtained from the magnetic separation in 160 g/L sodium hydroxide solution with a liquid to solid ratio of 8 mL/g at 125°C for 45 min, alumina was enriched in a bauxite concentrate with Al2O3 content of 53.30 wt.% and the mass ratio of alumina to silica (A/S) of 9.38, meeting the requirement of alumina production by the Bayer process.

Similar content being viewed by others

References

U.S. Geological Survey, Mineral Commodity Summaries, Bauxite and Alumina (2018). https://minerals.usgs.gov/minerals/pubs/commodity/bauxite/mcs-2018-bauxi.pdf

C. Liu, A. Feng, and Z. Guo, Physicochem. Probl. Miner. Process. 52, 2 (2016).

X. Li, S. Yu, W. Dong, Y. Chen, Q. Zhou, T. Qi, G. Liu, Z. Peng, and Y. Jiang, Hydrometallurgy 152, 183 (2015).

T. Le, S. Ju, L. Lu, P. Peng, L. Zhou, and S. Wang, Hydrometallurgy 169, 124 (2017).

H. Kahn, M. Tassinari, and G. Ratti, Miner. Eng. 16, 1313 (2003).

G. Li, F. Gu, Z. Peng, J. Luo, B. Deng, and T. Jiang, JOM 69, 1 (2016).

C.A. Pickles, T. Lu, B. Chambers, and J. Forster, Can. Metall. Q. 51, 424 (2013).

Z. Peng and J.Y. Hwang, Int. Mater. Rev. 60, 30 (2014).

G. Li, Q. Ye, B. Deng, J. Luo, M. Rao, Z. Peng, and T. Jiang, Hydrometallurgy 176, 62 (2018).

N. Papassiopi, K. Vaxevanidou, and I. Paspaliaris, Miner. Eng. 23, 25 (2010).

B. Gibsona, D.G. Wonyena, and S.C. Chelgani, Miner. Eng. 114, 64 (2017).

J. Liu, X. Wang, C. Lin, and J.D. Miller, Miner. Eng. 78, 58 (2015).

T. Jiang, G. Li, G. Qiu, X. Fan, and Z. Huang, Appl. Clay Sci. 40, 81 (2008).

G. Li, F. Gu, Z. Peng, J. Luo, B. Deng, and T. Jiang, in Light Metals 2017, The Minerals, Metals and Materials Series, ed. by A.P. Ratvik (Springer, New York, 2017), p. 75.

G. Li, J. Zeng, J. Luo, M. Liu, T. Jiang, and G. Qiu, Appl. Clay Sci. 99, 282 (2014).

G. Qiu, T. Jiang, G. Li, X. Fan, and Z. Huang, Scand. J. Metall. 33, 121 (2004).

V.I. Groudeva and S.N. Groudev, Travaux Icsoba, 13, 257 (1983).

G. Li, T. Jiang, G. Qiu, X. Fan, and H. Jiang, Trans. Nonferrous Metals Soc. 12, 132 (2002).

G. Li, J. Luo, T. Jiang, Z. Li, Z. Peng, and Y. Zhang, Metals 6, 294 (2016).

J. Luo, G. Li, M. Rao, J. Zhang, Y. Guo, and T. Jiang, J. Nonferr. Metal. 23, 3470 (2013).

S. Bi and H. Yu, The Production Process of Alumina (Beijing: Chemical Industry Press, 2006), pp. 65–70. (in Chinese).

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China under Grant 51234008, the Co-Innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources under Grant 2014-405, and the Fundamental Research Funds for the Central Universities of Central South University under Grants 502221803 and 502211823.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, F., Li, G., Peng, Z. et al. Upgrading Diasporic Bauxite Ores for Iron and Alumina Enrichment Based on Reductive Roasting. JOM 70, 1893–1901 (2018). https://doi.org/10.1007/s11837-018-3000-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3000-3