Abstract

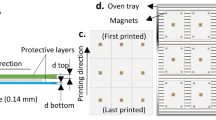

Microheater array powder sintering (MAPS) is a novel additive manufacturing process that uses an array of microheaters to selectively sinter powder particles. MAPS shows great promise as a new method of printing flexible electronics by enabling digital curing of conductive inks on a variety of substrates. For MAPS to work effectively, a microscale air gap needs to be maintained between the heater array and the conductive ink. In this article, we present an experimental MAPS printer with air gap control for printing conductive circuits. First, we discuss design aspects necessary to implement MAPS. An analysis is performed to validate that the design can maintain the desired air gap between the microheaters and the sintering layer, which consists of a silver nanoparticle ink. The printer is tested by printing conductive lines on a flexible plastic substrate with silver nanoparticle ink. Results show MAPS performs on par with or better than the existing fabrication methods for printed electronics in terms of both the print quality (conductivity of the printed line) and print speed, which shows MAPS’ great promise as a competitive new method for digital production of printed electronics.

Similar content being viewed by others

References

M. Gagliardi, Global Markets for Roll-to-Roll Technologies for Flexible Devices (Wellesley, MA: BCC Research, 2016).

Ceradrop, X-Serie, Product Specifications (Ceradrop). http://www.ceradrop.com/content/uploads/2016/04/CeraPrinter_X-Serie.pdf. Accessed 27 Nov 2017.

M. Hösel, R. Søndergaard, D. Angmo, and F. Krebs, Adv. Eng. Mater. 15, 995 (2013).

Y. Huang and N. Bu, Chin. Sci. Bull. 55, 3383 (2010).

K.C. Yung, X. Gu, C.P. Lee, and H.S. Choy, J. Mater. Process. Technol. 210, 2268–2272 (2010).

E. Sowade, H. Kang, and K. Mitra, J. Mater. Chem. C. 3, 11815 (2015).

M. Guillot, S. McCool, and K. Schroder, Proc. ASME Int. Mech. Eng. Congr. Expo. 7, 19 (2012).

K. Schroder, Nanotechnol. Conf. Expo 2, 220 (2011).

N. Holt, A. Van Horn, M. Montazeri, and W. Zhou, J. Manuf. Process. 31, 536 (2018).

N. Holt, L. Marques, A. Van Horn, M. Montazeri, and W. Zhou, Int. J. Adv. Manuf. Technol. (2017). https://doi.org/10.1007/s00170-017-1316-8.

OptoSigma, Sub-micron worm drive micrometer heads (OptoSigma). https://www.global-optosigma.com/en_us/Catalogs/pno/?from=page&pnoname=WGP&ccode=W8005&dcode=. Accessed 27 Nov 2017.

Newport, AJS100-20-127-S (Newport). https://www.newport.com/medias/sys_master/images/images/hd7/h43/8933920505886/AJS100-20-127-S.pdf. Accessed 27 Nov2017.

Automation Technology Inc., NEMA17 stepper motor (KL17H248-25-4A) for 3D printer, 67oz-in (Automation Technology). https://www.automationtechnologiesinc.com/products-page/featured-cnc-products/kl17h248-25-4a/. Accessed 27 Nov 2017.

J. Howard, O. Lieder, B. Bowlds, and P. Lindsay, US 7256588 B2 (Patent Grant, 2007). https://www.google.com/patents/US7256588. Accessed 27 Nov 2017.

A. Fleming, Sens. Actuators A 190, 106 (2012).

Y. Ganjeh, B. Song, K. Pagadala, K. Kim, S. Sadat, W. Jeong, K. Kurabayashi, E. Meyhofer, and P. Reddy, Rev. Sci. Instrum. 83, 105101 (2012).

B. Choi, M. Colburn, S. Sreenivasan, C. Willson, T. Bailey, and J. Ekerdt, US 6954275 B2 (Patent Grant, 2005). https://patents.google.com/patent/US6954275B2/en. Accessed 27 Nov 2017.

Schott Advanced Optics, Glass wafer specification (Schott Advanced Optics, 2016). http://www.us.schott.com/d/advanced_optics/ae285905-f939-4e0b-9b00-181feb764086/1.2/schott-glass-wafers-english-us-10082017.pdf. Accessed 27 Nov 2017.

DuPont Teijin Films, Melinex® ST506 Datasheet (DuPont Teijin Films). http://usa.dupontteijinfilms.com/wp-content/uploads/2017/01/ST506-Datasheet.pdf. Accessed 27 Nov 2017.

NovaCentrix, PSI-211® conductive screen ink datasheet (NovaCentrix, 2012). https://www.novacentrix.com/sites/default/files/pdf/PSI-211%20Data%20Sheet.pdf. Accessed 27 Nov 2017.

Affiliated Manufacturers Inc., MSP-485 precision screen printer brochure (AMI-Presco). http://www.ami-presco.com/downloads/485brochure.pdf. Accessed 27 Nov 2017.

P. Peng, A. Hu, and Y. Zhou, Appl. Phys. A 108, 685 (2012).

J. Kang, J. Ryu, H. Kim, and H. Hahn, J. Electron. Mater. 40, 2268 (2011).

Novacentrix, Metalon® JS-A101A and JS-A102A (NovaCentrix, 2017). https://www.novacentrix.com/sites/default/files/pdf/Metalon%20JS-A101A%20JS-A102A%20rev0.pdf. Accessed 27 Nov 2017.

Acknowledgements

We gratefully acknowledge the financial support from the Oak Ridge Associated Universities through the Ralph E. Powe Junior Faculty Enhancement Awards and from the University of Arkansas through the startup fund provided by the Vice Provost Office for Research and Economic Development. We thank Steven Brown for his assistance in building the experimental printer and Errol Porter and Clint Hardee for their assistance in developing the microheater array. Any opinions, findings, and conclusions or recommendations expressed in this publication are those of the authors and do not necessarily reflect the views of the University of Arkansas.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Holt, N., Zhou, W. Design and Fabrication of an Experimental Microheater Array Powder Sintering Printer. JOM 70, 1785–1792 (2018). https://doi.org/10.1007/s11837-018-2796-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2796-1