Abstract

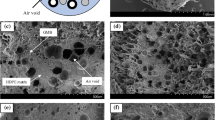

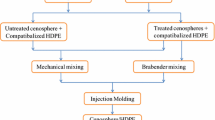

This work focuses on developing filaments of high-density polyethylene (HDPE) and their hollow particle-filled syntactic foams for commercial three-dimensional (3D) printers based on fused filament fabrication technology. Hollow fly-ash cenospheres were blended by 40 wt.% in a HDPE matrix to produce syntactic foam (HDPE40) filaments. Further, the recycling potential was studied by pelletizing the filaments again to extrude twice (2×) and three times (3×). The filaments were tensile tested at 10−4 s−1, 10−3 s−1, and 10−2 s−1 strain rates. HDPE40 filaments show an increasing trend in modulus and strength with the strain rate. Higher density and modulus were noticed for 2× filaments compared to 1× filaments because of the crushing of some cenospheres in the extrusion cycle. However, 2× and 3× filament densities are nearly the same, showing potential for recycling them. The filaments show better properties than the same materials processed by conventional injection molding. Micro-CT scans show a uniform dispersion of cenospheres in all filaments.

Similar content being viewed by others

References

I. Gibson, D. Rosen, and B. Stucker, Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing (New York: Springer, 2015), pp. 1–18.

M. Attaran, Bus. Horiz. 60, 677 (2017).

D.-A. Türk, F. Brenni, M. Zogg, and M. Meboldt, Mater. Des. 118, 256 (2017).

F. Chen, G. Mac, and N. Gupta, Mater. Des. 128, 182 (2017).

D. Cooper, J. Thornby, N. Blundell, R. Henrys, M.A. Williams, and G. Gibbons, Mater. Des. 69, 44 (2015).

F.P.W. Melchels, M.A.N. Domingos, T.J. Klein, J. Malda, P.J. Bartolo, and D.W. Hutmacher, Prog. Polym. Sci. 37, 1079 (2012).

W. Zhong, F. Li, Z. Zhang, L. Song, and Z. Li, Mater. Sci. Eng. A 301, 125 (2001).

M.L. Shofner, K. Lozano, F.J. Rodríguez-Macías, and E.V. Barrera, J. Appl. Polym. Sci. 89, 3081 (2003).

N. Gupta, S.E. Zeltmann, V.C. Shunmugasamy, and D. Pinisetty, JOM 66, 245 (2014).

N. Gupta, D. Pinisetty, and V.C. Shunmugasamy, Book Reinforced Polymer Matrix Syntactic Foams: Effect of Nano and Micro-Scale Reinforcement, (Springer, NJ: Springer Briefs in Materials, 2013), pp. 19–24.

B.R. Bharath Kumar, M. Doddamani, S.E. Zeltmann, N. Gupta, M.R. Ramesh, and S. Ramakrishna, Mater. Des. 2016, 414 (2016).

M.L. Jayavardhan, B.R. Bharath Kumar, M. Doddamani, A.K. Singh, S.E. Zeltmann, and N. Gupta, Compos. B Eng. 130, 119 (2017).

B.R. Bharath Kumar, M. Doddamani, S.E. Zeltmann, N. Gupta, M.R. Ramesh, and S. Ramakrishna, Data Brief 6, 933 (2016).

J.J.C. Picot, Polym. Eng. Sci. 24, 415 (1984).

S. Yin, R. Tuladhar, F. Shi, R. Shanks, M. Combe, and T. Collister, Polym. Eng. Sci. 55, 2899 (2015).

Acknowledgements

Mrityunjay Doddamani acknowledges the Department of Science and Technology, India, Grant DST/TSG/AMT/2015/394/G, and Visiting Scientist Fellowship Grant VSP 17-7-001 by the US Office of Naval research—Global (Program manager: Dr. Ramesh Kolar) to visit NYU for this work. Nikhil Gupta acknowledges the Office of Naval Research Grant N00014-10-1-0988. The views expressed in this article are those of authors, not of funding agencies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, A.K., Patil, B., Hoffmann, N. et al. Additive Manufacturing of Syntactic Foams: Part 1: Development, Properties, and Recycling Potential of Filaments. JOM 70, 303–309 (2018). https://doi.org/10.1007/s11837-017-2734-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2734-7