Abstract

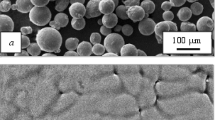

The microstructural degradation of the high Nb-TiAl alloy during the fabrication process by electron beam melting (EBM) is reported. The lamellar structure of as-EBM samples in the bottom part of the build shows significant microstructure degradation, resulting in deterioration of tensile properties at both ambient and high temperatures. Microstructural analysis has been conducted by electron backscattered diffraction and transmission Kikuchi diffraction microscopy. The results show that the degradation of the lamellar structure is not only caused by the coarsening under the high-frequency thermal cycling during the fabrication of following layers but also attributed by the discontinuous dynamic recrystallization of the unstable initial lamellar structure resulting from the rapid solidification.

Similar content being viewed by others

References

Y.W. Kim, Symposium on Gamma Titanium Aluminides, at the TMS 95 Annual Meeting, 637 (1995).

F. Appel, U. Brossmann, U. Christoph, U. Eggert, P. Janschek, and J. Paul, Adv. Eng. Mater. 2, 699 (2002).

Y.W. Kim, JOM 41, 24 (1989).

D. Hu, A.B. Godfrey, and M.H. Loretto, Intermetallics 6, 413 (1998).

X. Du, J. Zhu, X. Zhang, Z. Cheng, and Y.W. Kim, Scripta Mater. 43, 597 (2000).

Z. Huang, Intermetallics 37, 11 (2013).

L. Zhou, V. Lupinc, and J.T. Guo, Mater. Sci. Eng. A 354, 97 (2003).

Z. Huang, W. Voice, and P. Bowen, Scripta Mater. 48, 79 (2003).

D.B. Williams and E.P. Butler, Inter. Metals. Rev. 26, 153 (1981).

J. Kranz, D. Herzog, and C. Emmelmann, J. Laser Appl. S14001, 27 (2015).

T. Cheng, Intermetallics 995, 7 (1999).

B. Chen, P.E.J. Flewitt, A.C.F. Cocks, and D.J. Smith, Int. Mater. Rev. 1, 60 (2015).

W. Zhao, Y. Pei, D. Zhang, Y. Ma, S. Gong, and H. Xu, Intermetallics 429, 19 (2011).

H. Jiang, T. Rong, D. Hu, I.P. Jones, and W. Voice, Intermetallics 1433, 14 (2006).

S. Xu, X. Xu, Y. Xu, Y. Liang, and J. Lin, Mater. Des. 101, 88 (2016).

L. Fang, J. Lin, and X. Ding, Mater. Chem. Phys. 112, 167 (2015).

T. Parthasarathy, M. Keller, and M.G. Mendiratta, Scripta Mater. 1025, 38 (1998).

A. Chatterjee, H. Mecking, and E. Arzt, Mater. Sci. Eng. A 840, 329 (2002).

S. Bystrzanowski, A. Bartels, H. Clemens, R. Gerling, F.P. Schimansky, G. Dehm, and H. Kestler, Intermetallics 515, 13 (2005).

Y. Zong, D. Wen, Z. Liu, and D. Shan, Mater. Des. 321, 91 (2016).

H. Niu, Y. Chen, Y. Zhang, J. Lu, W. Zhang, and P. Zhang, Mater. Des. 196, 90 (2016).

Z. Huang and T. Cong, Intermetallics 18, 161 (2010).

K.S. Chan and Y.W. Kim, Acta Metall. Mater. 439, 43 (1995).

D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann, Acta Mater. 371, 117 (2016).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 51671016). Bo Chen acknowledges financial supports by the U.K.’s Engineering and Physical Sciences Research Council, EPSRC (EP/P025978/1), and Coventry University through the Early Career Researcher–Outgoing Mobility Award to facilitate this international research collaboration.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kan, W., Liang, Y., Peng, H. et al. Microstructural Degradation of Ti-45Al-8Nb Alloy During the Fabrication Process by Electron Beam Melting. JOM 69, 2596–2601 (2017). https://doi.org/10.1007/s11837-017-2592-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2592-3