Abstract

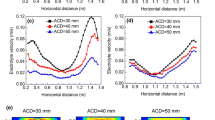

Numerical simulations of gas–liquid two-phase flows in aluminum electrolysis cells using the Euler–Euler approach were presented. The attempt was made to assess the performance and applicability of different interphase forces (drag, lift, wall lubrication, and turbulent dispersion forces) and turbulence models (standard k–ε, renormalization group k–ε, standard k–ω, shear stress transport k–ω, and Reynolds stress models). Moreover, three different bubble-induced turbulence models have been also analyzed. The simulated electrolyte velocity profiles were discussed by comparing with each other and against published experimental data. Based on the results of the validation of different interphase forces and turbulence models, a set consisting of the dispersed standard k–ε model, Grace drag coefficient model, Simonin turbulent dispersion force model, and Sato et al.’s bubble-induced effective viscosity model was found to provide the best agreement with the experimental data. The prediction results showed that the contributions of the lift force and the wall lubrication force can be neglected for the present bubbly flows.

Similar content being viewed by others

References

Y.X. Liu and J. Li, Modern Aluminum Electrolysis (Beijing: Metallurgical Industry Press, 2008), pp. 3–8.

M.A. Cooksey, M.P. Taylor, and J.J.J. Chen, JOM 60, 51 (2008).

L.I. Kiss, A.L. Perron, S. Poncsak, and T.N. Guyen, Light Metals 2007, ed. M. Sørlie (Orlando: TMS, 2007), pp. 495–500.

Y.Q. Feng, W. Yang, M.A. Cooksey, and M.P. Schwarz, J. Comput. Multiph. Flows 2, 179 (2010).

S.Q. Zhan, M. Li, J.M. Zhou, J.H. Yang, and Y.W. Zhou, Light Metals 2014, ed. J. Grandfield (San Diego: TMS, 2014), pp. 777–782.

R. Oey, R. Mudde, and H. Van den Akker, AIChE J. 49, 1621 (2003).

N.J. Zhou, X.X. Xia, F.Q. Wang, and J. Cent, South Univ. T. 14, 42 (2007).

J. Li, Y.J. Xu, H.L. Zhang, and Y.Q. Lai, Int. J. Multiph. Flow 37, 46 (2011).

Y.Q. Feng, M.P. Schwarz, W. Yang, and M.A. Cooksey, Metall. Mater. Trans. B 46, 1959 (2015).

M. Ishii and N. Zuber, AIChE J. 25, 843 (1979).

L.A. Schiller and Z. Nauman, Ver. Dtsch. Ing. 77, 135 (1935).

M.V. Tabib, S.A. Roy, and J.B. Joshi, Chem. Eng. J. 139, 589 (2008).

R. Rzehak and E. Krepper, Int. J. Multiph. Flow 55, 138 (2013).

Y. Sato, M. Sadatomi, and K. Sekoguchi, Int. J. Multiph. Flow 7, 167 (1981).

M.A. Cooksey and W. Yang, Light Metals 2006, ed. T.J. Galloway (San Antonio: TMS, 2006), pp. 359–365.

ANSYS Inc., ANYSYS Fluent 14.5 User’s Guide (Canonsburg: Fluent Inc., 2012).

S.Q. Zhan, M. Li, J.M. Zhou, J.H. Yang, and, Y.W. Zhou, J. Cent. South Univ. T. 22, 2482 (2015).

S.Q. Zhan, Ph.D. Dissertation, Central South University, Changsha, 2015.

C. Simonin and P.L. Viollet, Int. J. Numer. Methods Fluids 91, 65 (1990).

A.A. Troshko and Y.A. Hassan, Int. J. Multiph. Flow 27, 1965 (2001).

Acknowledgements

The authors are grateful for the financial support of the National Natural Science Foundation of China (11502097), the Natural and Science Foundation of Jiangsu Province (BK20130478), the Foundation of Senior Talent of Jiangsu University (2015JDG158), and the China Postdoctoral Science Foundation (2016M591781). Our special thanks are due to Dr. Feng’s Group for assistance with the experiments and valuable discussions and to the anonymous reviewers for insightful suggestions on this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Fig. S1

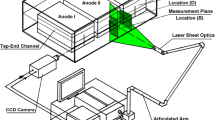

Geometry and griding of the three-anode model: (a) Inlet and outlet boundary conditions, (b) PIV measurement, (c) Cell geometry, (d) Grid geometry in the horizontal plane, and (e) Grid geometry in the vertical plane (TIFF 1946 kb)

Fig. S2

Comparisons of gas volume fraction distributions at a horizontal plane (z = 0.03 m) for different grid cells: (a) Grid1, (b) Grid2, (c) Grid3, (d) Grid4, and (e) Grid5 (TIFF 919 kb)

Fig. S3

Comparisons of vertical electrolyte profiles for different grid cells (TIFF 118 kb)

Rights and permissions

About this article

Cite this article

Zhan, S., Yang, J., Wang, Z. et al. CFD Simulation of Effect of Interphase Forces and Turbulence Models on Gas–Liquid Two-Phase Flows in Non-Industrial Aluminum Electrolysis Cells. JOM 69, 1589–1599 (2017). https://doi.org/10.1007/s11837-017-2327-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2327-5