Abstract

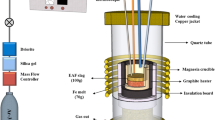

Effects of temperature and slag basicity on the reduction rate of iron oxide in molten synthetic electric arc furnace oxidizing slag by Al-40 wt.%Fe alloy was investigated. An alloy sample was dropped into molten slag in an MgO crucible. When the initial slag temperature was 1723 K, there was no reduction. However, when the initial slag temperature was 1773 K and the slag basicity was 1.1, the reduction was initiated and the temperature of the slag rapidly increased. When the slag basicity was 1.1, increasing the initial slag temperature from 1773 K to 1823 K increases the reaction rate. As the slag basicity increased from 1.1 to 1.4 at 1773 K, the reaction rate increased. From SEM analysis, it was found that an Al2O3 or a spinel phase at the slag-metal interface inhibited the reaction at a lower temperature and a lower slag basicity.

Similar content being viewed by others

References

Korea Iron and Steel Association: The 2014 Korean Steel Industry Yearbook (Seoul, South Korea: S&M Media, 2014), p. 608.

I. Liapis and I. Papayianni, J. Hazardous Mater. 283, 89 (2015).

R.M. Santos, D. Ling, A. Sarvaramini, M. Guo, J. Elsen, F. Larachi, G. Beaudoin, B. Blanpain, and T.V. Gerven, Chem. Eng. J. 203, 239 (2012).

S.S. Jung and I. Sohn, Environ. Sci. Technol. 48, 1886 (2014).

C. Barca, S. Troesch, D. Meyer, P. Drissen, Y. Andres, and F. Chazarenc, Environ. Sci. Technol. 47, 549 (2013).

F. Engström, D. Adolfsson, Q. Yang, C. Samuelsson, and B. Björkman, Steel Res. Int. 81, 362 (2010).

J.H. Kim, S.W. Joo, D.J. Kim, S.Y. Kim, J.I. Hwang, H.C. Lee, and B.D. You, Korean J. Met. Mater. 52, 791 (2014).

K. Morita, M. Guo, N. Oka, and N. Sano, J. Mater. Cycles Waste Manag. 4, 93 (2002).

T. Kim and J. Lee, Mater. Trans. 52, 2233 (2011).

Y.-B. Kang, T. Kim, and J. Lee, Ironmaking Steelmaking 39, 498 (2012).

S.B. An, M.S. Shin, K.J. Sim, and J. Lee, Met. Mater. Int. 2, 351 (2014).

E. Shibata, S. Egawa, and T. Nakamura, ISIJ Int. 42, 609 (2002).

J.H. Park, H.S. Song, and D.J. Min, ISIJ Int. 44, 790 (2004).

S. Taira, K. Nakashima, and K. Mori, ISIJ Int. 33, 116 (1993).

S. Zhang, H.R. Rezaie, H. Sarpoolaky, and W.E. Lee, J. Am. Ceram. Soc. 83, 897 (2000).

K. Nagata, N. Sata, and K. Goto, Tetsu-to-Hagane 13, 20 (1982).

Y. Chung and A.W. Cramb, Metall. Mater. Trans. B 31, 957 (2000).

Acknowledgements

The authors would like to express thanks to the Industrial Strategy Technology Development (No. 10035258, Development of Green Process for Production of Eco-steel Slag) for the financial support through a grant provided by the Ministry of Knowledge Economy, Republic of Korea. This work was partially supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (No. NRF-2014R1A2A2A01007011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J., Oh, J.S. & Lee, J. Reduction Kinetics of Electric Arc Furnace Oxidizing Slag by Al-Fe Alloy. JOM 68, 2359–2364 (2016). https://doi.org/10.1007/s11837-016-2022-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2022-y