Abstract

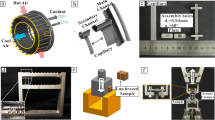

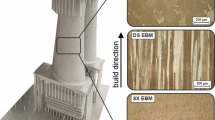

Oil–gas separation is a key process in an aero-engine lubrication system. This study reports an innovative development in oil–gas separation. A honeycomb-structured rotor with hexagonal cone-shaped pore channels has been designed, additively manufactured from Ti-6Al-4V using selective electron beam melting (SEBM) and assessed for oil–gas separation for aero-engine application. The Ti-6Al-4V honeycomb structure showed a high compressive strength of 110 MPa compared to less than 20 MPa for metal foam structures. The oil–gas separation efficiency of the honeycomb-structured separation rotor achieved 99.8% at the rotation speed of 6000 rpm with much lower ventilation resistance (17.3 kPa) than that of the separator rotor constructed using a Ni-Cr alloy foam structure (23.5 kPa). The honeycomb-structured Ti-6Al-4V separator rotor produced by SEBM provides a promising solution to more efficient oil–gas separation in the aero-engine lubrication system.

Similar content being viewed by others

References

C.N. Eastwick, K. Simmons, Y. Wang, and S. Hibberd, Inst. Mech. Eng. Part A 220, 770–771 (2006).

B. Chandra, K. Simmons, S. Pickering, and M. Tittel (Paper presented at ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, Scotland, 2010), pp. 219–228.

C. Eastwick, S. Hibberd, K. Simmons, Y. Wang, I. Care, and A. Aroussi (Paper presented at ASME Turbo Expo 2002: Pressure Vessels and Piping Conference, Amsterdam, The Netherlands, 2002), pp. 215–220.

X.X. Cai, D. Xiong, and K.L. Zhou, Vocat. Tech. Coll. 8, 23 (2008).

S. Smith, US Patent 4049401.

K. Willenborg and M. Klingsporn, (Paper presented at Proceedings of GT2006 ASME Turbo Expo, Barcelona, Spain, 2006).

Air/oil separators, http://www.dunlop-equipment.com/prod_air_oil_seprtrs.htm. Accessed 22 August 2015.

A.W. Elias, A Systematic Study on the Mechanical and Thermal Properties of Open Cell Metal Foams for Aerospace Applications (North Carolina State University, 2004).

V. Paserin, S. Marconson, J. Shu, and D. Vilkinson, Adv. Eng. Mater. 6, 454 (2004).

J. Barnhart, Prog. Mater Sci. 46, 559 (2001).

H. Choe and D.C. Dunand, Mater. Sci. Eng. A 384, 184–193 (2004).

O. Smorygo, V. Mikutski, A. Leonov, A. Marukovich, and Y. Vialiuha, Scripta Mater 58, 910–913 (2008).

H. Choe and D.C. Dunand, Acta Mater. 52, 1283–1295 (2004).

J. Lorenz and R. Zhofen, US patent 4714139.

A.D. Krul and J. Fla, US patent 5716423.

P. Gennaro, M. Romeo, G. Bene, F. Tortorola, and G.P. Zanon, in particular for a rotary separator, EP 2156941 A1 and EP 2156 941 B1.

S.L. Lu, H.P. Tang, Y.P. Ning, N. Liu, D.H. StJohn, and M. Qian, Metall. Mater. Trans. A 46, 3824–3834 (2015).

Acknowledgements

This work was funded by the Ministry of Science and Technology China under the National High Technology Research Program (No. 2013AA031103) and the National Natural Science Foundation of China (No. 51528401). M. Qian was a Guest Research Professor of the State Key Laboratory of Porous Metal Materials, NIN for the project period of January 2012 to June 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, H.P., Wang, Q.B., Yang, G.Y. et al. A Honeycomb-Structured Ti-6Al-4V Oil–Gas Separation Rotor Additively Manufactured by Selective Electron Beam Melting for Aero-engine Applications. JOM 68, 799–805 (2016). https://doi.org/10.1007/s11837-015-1778-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1778-9