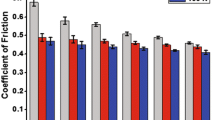

The wear of polyoxymethylene (POM) is considered a key design parameter of polymer gears and some mechanical applications, and it determines the service time span. This work investigates the influence of carbon nanotubes (CNTs) on the specific wear rate of POM/CNT nanocomposites by using a pin-on-disk test rig (sliding only). The CNTs were synthesized with a fully automatic machine via the arc-discharge multi-electrode technique and subsequently dispersed in a POM matrix to manufacture test specimens. The CNT weight percentages were varied within the range 0–0.03 wt.% in three different operating media (air, distilled water, and mineral oil). The wear mechanism was examined by microscopy. The mechanical and thermal properties of POM/CNT were studied by using calorimetric analysis and by mechanical tensile testing. In addition, the thermal and mechanical properties were improved to an optimum CNT ratio of 0.02 wt.% due to the improvement in crystallinity of POM and a decrease in the fusion defects. The crystallinity degree increased by 7%, and the melting temperature also increased. The results further indicate that the specific wear rate (Ws) for POM/CNT containing 0.03 wt.% CNT in air and water media was improved by 73% and 66%, respectively, compared with virgin POM. In addition, the tensile strength of the mechanical properties and Young’s modulus increased by 31% and 29%, respectively.

Similar content being viewed by others

References

J.X. Li, I.N. Ness, and W.L. Cheunc, J. Appl. Polym. Sci. 59, 1733 (1996).

Y.J. Mergler, R.P. Schaake, and A.J. VeldHuisint, Wear 256, 294 (2004).

K. Mao, Wear 262, 432 (2007).

H. Unal, A. Mimaroglu, and Z. Demir, Int. J. Polym. Mater. 59, 808 (2010).

T. Huang, R. Lu, H. Wang, M. Yuning, J. Tian, and T. Li, J. Macromol. Sci. B 50, 1235 (2011).

J. He, L. Zhang, C. Li, B. Yan, and R. Tang, J. Macromol. Sci. B 50, 2023 (2011).

A. Pogacnik and M. Kalin, Wear 290–291, 140 (2012).

B. Aldousiri, A. Shalwan, and C.W. Chin, Adv. Mater. Sci. Eng. (2013). doi:10.1155/2013/645923.

J. Stryczek, S. Bednarczyk, and K. Biernacki, Arch. Civil Mech. Eng. 14, 391 (2014).

S. Yousef, T.A. Osman, M. Khattab, A.A. Bahr, and A.M. Youssef, Adv. Tribol. (2015). doi:10.1155/2015/926918.

L.-H. Sun, Z.-G. Yang, and X.-H. Li, Wear 264, 693 (2008).

L. Agnieszka and P. Krzysztof, Mater. Sci. Forum 714, 201 (2012).

A.K. Das, S. Suin, N.K. Shrivastava, S. Maiti, J.K. Mishra, and B.B. Khatua, Polym. Composit. 35, 273 (2014).

B. Dong, Z. Yang, Y. Huang, and H.L. Li, Tribol. Lett. 20, 251 (2005).

Y. Liu and S.K. Sinha, Wear 300, 44 (2013).

H. Meng, G.X. Sui, G.Y. Xie, and R. Yang, Composit. Sci. Technol. 69, 606 (2009).

X. Zhao and L. Ye, Compos. Part B 42, 926 (2011).

X. Zhao and L. Ye, J. Polym. Sci. B 48, 905 (2010).

X. Zhao and L. Ye, Compos. Sci. Technol. 71, 1367 (2011).

Z. Jiang, Y. Chen, and Z. Liu, J. Polym. Res. 21, 451 (2014).

S. Yousef, A. Khattab, M. Zak, and T.A. Osman, IEEE Trans. Nanotechnol. 12, 616 (2013).

S. Yousef, T.A. Osman, A.H. Abdalla, and G.A. Zohdy, JOM (2014). doi:10.1007/s11837-014-1268-5.

S. Yousef, A. Khattab, T.A. Osman, and M. Zaki, J. Nanomater. (2013). doi:10.1155/2013/392126.

S. Yousef, A. Khattab, T.A. Osman, and M. Zak, Paper presented at the International Conference on Innovative Engineering Systems (ICIES), IEEE, Alexandria, 7–9 December 2012.

A. Valenza, A.M. Visco, L. Torrisi, and N. Campo, Polymer 45, 1707 (2004).

S. Xie, S. Zhang, H. Liu, G. Chen, M. Feng, H. Qin, F. Wang, and M. Yang, Polymer 46, 5417 (2005).

F. Alam, A. Kumar, A.K. Patel, R.K. Sharma, and K. Balani, JOM 67, 688 (2015).

S. Yousef, Polymer Nanocomposite Components: A Case Study on Gears (Woodhead, Cambridge, in press).

S. Liu, F. Wang, J. Chen, and Y. Cao, Int. J. Polym. Anal. Charact. 20, 138 (2015).

J. Chen, Y. Cao, and L. Huilin, J. Appl. Polym. Sci. 101, 48 (2006).

W.J. Wood, R.G. Maguire, and W.H. Zhong, Compos. B 42, 584 (2011).

A. Golchin, G.F. Simmons, S. Glavatskih, and B. Prakash, Proc. Inst. Mech. Eng. J 227, 811 (2013).

S. Bhaumik, S. Prabhu, and K.J. Singh, Adv. Tribol. (2014). doi:10.1155/2014/341365.

Acknowledgement

This research was supported by “Emmag- Erasmus Mundus Maghreb & Egypt.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yousef, S., Visco, A.M., Galtieri, G. et al. Wear Characterizations of Polyoxymethylene (POM) Reinforced with Carbon Nanotubes (POM/CNTs) Using the Paraffin Oil Dispersion Technique. JOM 68, 288–299 (2016). https://doi.org/10.1007/s11837-015-1674-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1674-3