Abstract

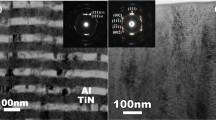

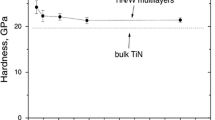

We present in situ indentation in a transmission electron microscope on Al-TiN multilayers with individual layer thicknesses of 50 nm and 2.7 nm to explore the effect of length scales on the plastic co-deformability of a metal and a ceramic. At 50 nm, plasticity was confined to the Al layers with brittle fracture in the TiN layers. At 5 nm and below, cracking in TiN was suppressed with co-deformation evident in both layers. The in situ transmission electron microscopy (TEM) straining results demonstrate a profound size effect in enhancing plastic co-deformability in nanoscale metal-ceramic multilayers, as well as direct validation of ex situ and 3-D elastic–plastic deformation models.

Similar content being viewed by others

References

I.J. Beyerlein, A. Caro, M.J. Demkowicz, N.A. Mara, A. Misra, and B.P. Uberuaga, Mater. Today 16, 443 (2013).

W. Han, M.J. Demkowicz, N.A. Mara, E.G. Fu, S. Sinha, A.D. Rollett, Y.Q. Wang, J.S. Carpenter, I.J. Beyerlein, and A. Misra, Adv. Mater. 25, 6975 (2013).

N. Mara and I.J. Beyerlein, J. Mater. Sci. 49, 6497 (2014).

M.J. Demkowicz, R.G. Hoagland, and J.P. Hirth, Phys. Rev. Lett. 100, 1361021 (2008).

N.A. Mara, D. Bhattacharyya, P. Dickerson, R.G. Hoagland, and A. Misra, Appl. Phys. Lett. 92, 231901 (2008).

N.A. Mara, D. Bhattacharyya, J.P. Hirth, P. Dickerson, and A. Misra, Appl. Phys. Lett. 97, 021909 (2009).

I. Knorr, N.M. Cordero, E.T. Lilleodden, and C.A. Volkert, Acta Mater. 61, 4984 (2013).

M.A. Monclus, M. Karlik, M. Callisti, E. Frutos, J.L. Lorca, T. Polcar, and J.M. Molina-Aldareguia, Thin Solid Films 571, 275 (2013).

S. Lotfian, M. Rodriguez, K.E. Yazzie, N. Chawla, J. Llorca, and J.M. Molina-Aldareguia, Acta Mater. 61, 4439 (2013).

A. Misra, J.P. Hirth, and R.G. Hoagland, Acta Mater. 53, 4817 (2005).

A. Misra, X. Zhang, D. Hammon, and R.G. Hoagland, Acta Mater. 53, 221 (2005).

J. Wang, R.G. Hoagland, J.P. Hirth, and A. Misra, Acta Mater. 56, 3109 (2008).

N. Li, J. Wang, A. Misra, and J.Y. Huang, Microsc. Microanal. 18, 1155 (2012).

F. Ebrahimi and D. Kong, Scr. Mater. 40, 609 (1999).

A. Misra, M. Verdier, Y.C. Lu, H. Kung, T.E. Mitchell, M. Nastasi, and J.D. Embury, Scr. Mater. 39, 555 (1998).

D. Mitlin, A. Misra, V. Radmilovic, M. Nastasi, R.G. Hoagland, D.J. Embury, J.P. Hirth, and T.E. Mitchell, Philos. Mag. 84, 719 (2004).

M. Ardeljan, M. Knezevic, T. Nicolek, I.J. Beyerlein, S.J. Zheng, J.S. Carpenter, R.J. McCabe, N.A. Mara, T.M. Pollock, and , IOP Conf. Ser. Mater. Sci. Eng. 63, 012170 (2014).

Y. Kim, A.S. Budiman, J.K. Baldwin, N.A. Mara, A. Misra, and S.M. Han, J. Mater. Res. 27, 592 (2012).

E.G. Fu, N. Li, A. Misra, R.G. Hoagland, H. Wang, and X. Zhang, Mater. Sci. Eng. A 493, 283 (2008).

N. Li, J. Wang, J.Y. Huang, A. Misra, and X. Zhang, Scr. Mater. 63, 363 (2010).

M.J. Demkowicz and L. Thilly, Acta Mater. 59, 7744 (2011).

N. Li, M. Nastasi, and A. Misra, Int. J. Plast. 32, 1 (2012).

S. Zheng, J.S. Carpenter, R.J. McCabe, I.J. Beyerlein, and N.A. Mara, Sci. Rep. 4, 4226 (2014).

N.A. Mara and I.J. Beyerlein, Curr. Opin. Solid State Mater. Sci. (2015). doi:10.1016/j.cossms.2015.04.002.

W.D. Kingery, H.K. Bowen, and D.R. Uhlmann, Introduction to Ceramics, 2nd ed. Wiley series on the science and technology of materials. (New York: Wiley, 1976), p. c1976.

L.E. Toth, Transition Metal Carbides and Nitrides (Waltham: Academic Press, 1971), p. 279.

A.M. Minor, E.A. Morris Jr., J.W. Stach, I. Morris Jr., and I. Petrov, J. Electron. Mater. 32, 1023 (2003).

M. Odén, H. Ljungcrantz, and L. Hultman, J. Mater. Res. 12, 2134 (1997).

J.D. Embury and J.P. Hirth, Acta Metall. Mater. 42, 2051 (1994).

D. Bhattacharyya, N.A. Mara, P. Dickerson, R.G. Hoagland, and A. Misra, Philos. Mag. 90, 1711 (2010).

N. Li, H. Wang, A. Misra, and J. Wang, Sci. Rep. 4, 6633 (2014).

D. Bhattacharyya, N.A. Mara, R.G. Hoagland, and A. Misra, Scr. Mater. 58, 981 (2008).

A.T. Alpas, J.D. Embury, D.A. Hardwick, and R.W. Springer, J. Mater. Sci. 25, 1603 (1990).

H. Fujita and T. Tabata, Acta Metall. 21, 355 (1973).

M.D. Uchic, D.M. Dimiduk, R. Wheeler, P.A. Shade, and H.L. Fraser, Scr. Mater. 54, 759 (2006).

D. Bhattacharyya, N.A. Mara, P. Dickerson, R.G. Hoagland, and A. Misra, Acta Mater. 59, 3804 (2011).

J. Wang and A. Misra, Curr. Opin. Solid State Mater. Sci. 18, 19 (2014).

J.P. Hirth and J. Lothe, Theory of Dislocations (New York: Krieger, 1982).

Acknowledgements

The authors gratefully acknowledge support from the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science. Los Alamos National Laboratory, an affirmative action equal opportunity employer, is operated by Los Alamos National Security, LLC, for the National Nuclear Security Administration of the U.S. Department of Energy under Contract DE-AC52-06NA25396.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mara, N.A., Li, N., Misra, A. et al. Interface-Driven Plasticity in Metal–Ceramic Nanolayered Composites: Direct Validation of Multiscale Deformation Modeling via In Situ Indentation in TEM. JOM 68, 143–150 (2016). https://doi.org/10.1007/s11837-015-1542-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1542-1