Abstract

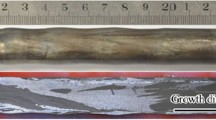

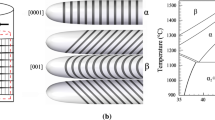

As a promising electromagnetic process to obtain TiAl samples without contamination, electromagnetic confinement and directional solidification was successfully applied for lamellar microstructure control in Ti-47Al alloy. Seeded by a Ti-43Al-3Si seed, columnar α grains grew stably and the lamellae within these grains were aligned parallel to the growth direction. However, stray α or β grains, in which the lamellae were complex, nucleated and grew in the sample edge. The possible reasons for the formation of stray grains were discussed by analyzing the temperature gradient at the solid/liquid interface and the macrosegregation of Ti5Si3 particles and Al solute along the sample radius. Moreover, the fluid flow induced by electromagnetic force, which led to the macrosegregation, was also discussed by using a simple model.

Similar content being viewed by others

References

Y.-W. Kim, JOM 46, 30 (1994).

K.S. Chan, JOM 49, 53 (1997).

X.H. Wu, Intermetallics 14, 1114 (2006).

J. Lapin, T. Pelachová, and M. Dománková, Intermetallics 19, 814 (2011).

M. Yamaguchi, H. Inui, and K. Ito, Acta Mater. 48, 307 (2000).

D.R. Johnson, H. Inui, S. Muto, Y. Omiya, and T. Yamanaka, Acta Mater. 54, 1077 (2006).

D.R. Johnson, Y. Masuda, H. Inui, and M. Yamaguchi, Acta Mater. 45, 2523 (1997).

A.H. Liu, B.S. Li, H. Nan, Y.W. Sui, J.J. Guo, and H.Z. Fu, Rare Met. Mater. Eng. 37, 956 (2008).

J.L. Fan, X.Z. Li, Y.Q. Su, R.R. Chen, J.J. Guo, and H.Z. Fu, Trans. Nonferrous Met. Soc. China 22, 1073 (2012).

J. Lapin and L. Ondrúš, Kovové Mater. 40, 161 (2002).

H.N. Lee, D.R. Johnson, H. Inui, M.H. Oh, D.M. Wee, and M. Yamaguchi, Acta Mater. 48, 3221 (2000).

M. Takeyama, Y. Yamamoto, H. Morishima, K. Koike, S.Y. Chang, and T. Matsuo, Mater. Sci. Eng. A 329, 7 (2002).

S.M. Li, J.S. Li, Q.T. Hao, H.C. Kou, J.G. Li, and H.Z. Fu, J. Mater. Process. Tech. 137, 204 (2003).

J. Shen, J.G. Li, and H.Z. Fu, J. Mater. Process. Tech. 102, 109 (2000).

C.J. Song, G.F. Liang, Z.M. Xu, J. Shen, and J.G. Li, J. Mater. Process. Tech. 180, 179 (2006).

Y.J. Du, J. Shen, Y.L. Xiong, Z.W. Liu, Q. Zhao, and H.Z. Fu, JOM 66, 1914 (2014).

M. Yamaguchi, D.R. Johnson, H.N. Lee, and H. Inui, Intermetallics 8, 511 (2000).

X.Z. Li, T. Sun, C.X. Yu, Y.Q. Su, Y.Z. Cao, J.J. Guo, and H.Z. Fu, Acta Metall. Sin. 45, 1479 (2009).

D.R. Johnson, Y. Masuda, H. Inui, and M. Yamaguchi, Mat. Sci. Eng. A. 239, 577 (1997).

W.Z. Luo, J. Shen, Z.X. Min, and H.Z. Fu, J. Cryst. Growth 310, 5441 (2008).

F.H. Froes, C. Suryanarayana, and D. Eliezer, J. Mater. Sci. 27, 5113 (1992).

J.-C. Chen and C. Hu, J. Cryst. Growth 158, 289 (1996).

C. Hu and J.-C. Chen, Int. J. Heat Mass Transf. 39, 3347 (1996).

H.T. Zhang, H. Nagaumi, and J.Z. Cui, Mater. Sci. Eng. A 448, 177 (2007).

J. Sakane, B.Q. Li, and J.W. Evans, Metall. Trans. B 19, 397 (1988).

B.Q. Li, J. Mater. Process. Tech. 55, 351 (1995).

G. Zimmermann, L. Sturz, and J. Dagner, 5th International Symposium on Electromagnetic Processing of Materials, Sendai (2006), p. 375.

W.D. Griffiths and D.G. McCartney, Mater. Sci. Eng. A 222, 140 (1997).

Acknowledgements

This work is supported by the National Natural Science Foundation of China under Grant No. 51174167, and the Research Fund of State Key Laboratory of Solidification Processing (NWPU), China under Grant No. 63-TP-2011. It is also supported by the Doctorate Foundation of Northwestern Polytechnical University under Contract No. CX201308.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, Y., Shen, J., Xiong, Y. et al. Lamellar Microstructure Alignment in Ti-47Al Alloy by Electromagnetic Confinement and Directional Solidification Using a Seed. JOM 67, 1258–1264 (2015). https://doi.org/10.1007/s11837-015-1438-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1438-0