Abstract

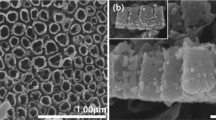

The mechanical stability of biomedical Ti6Al4V rods with vertically aligned nanotubes structure formed on their surface has yet to be fully tested during insertion into the bone. The surface of rods impacted during insertion into a bone makes shear contact with bone, generating an interfacial stress. This stress plays an important role in osseointegration and may contribute to loosening between the bone and the implant during surgery. In the current study, the mechanical stability of various Ti6Al4V surfaces, including machined (M), rough (R), machined-anodized (MA), and rough-anodized (RA) surfaces, were tested and fully analyzed during insertion and pullout test into a simulant bone with densities 15 and 20 pounds per cubic foot (pcf). Our initial results from the field emission scanning electron microscopy images taken before and after insertion reveal that titania nanotubes remained stable and maintained their structural integrity during the insertion and pullout Instron test. Furthermore, from the interfacial stress calculation during the insertion, it was observed that compared with nonanodized rods, a higher force was required to insert the anodized rods. The interfacial stress generated during the insertion of anodized rods was 1.03 ± 0.11 MPa for MA and 1.10 ± 0.36 MPa for RA, which is significantly higher (p < 0.05) than nonanodized rods with 0.36 ± 0.07 MPa for M and 0.36 ± 0.08 MPa for R in simulant bone with density of 15 pcf. Similar behavior was also observed in 20 pcf simulant bone. Energy dissipated during anodized rod insertion (i.e., MA = 1.3 ± 0.04 Nm and RA = 1.23 ± 0.24 Nm) was not significantly different than nonanodized rod insertion (i.e., M = 0.9 ± 0.05 Nm and R = 1.04 ± 0.04 Nm) into 15 pcf simulant bone. The high stress during insertion of anodized rods suggests that the nanotubes on the surface can cause gripping and high friction on the radial side, resisting the counter motion of the bone. The latter may play a beneficial role in preventing micromotion between the bone and implant and therefore reducing the chance of fretting/fatigue corrosion.

Similar content being viewed by others

References

Inpatient Surgery, in Health, Office of Information Services, 2 (2010).

Joint Revision Surgery—When Do I Need It? OrthoInfo (2007), http://orthoinfo.aaos.org/topic.cfm?topic=A00510.

A. Tabassum, G.J. Meijer, X.F. Walboomers, and J.A. Jansen, Clin. Oral Impl. Res. 25, 487 (2014).

F. Javed, H.B. Ahmed, R. Crespi, and G.E. Romanos, Intervent. Med. Appl. Sci. 5, 6 (2013).

P. Rao and A. Gill, J. Dental Impl. 2, 103 (2012).

D. Regonini, C.R. Bowen, A. Jaroenworaluck, and R. Stevens, Mater. Sci. Eng. 74, 377 (2013).

S. Oh, C. Daraio, L.H. Chen, T.R. Pisanic, R.R. Finones, and S. Jin, J. Biomed. Mater. Res. Part A 78A, 97 (2006).

G. Balasundaram, C. Yao, and T.J. Webster, J. Biomed. Mater. Res. Part A 84A, 447 (2008).

K.S. Brammer, S. Oh, C.J. Cobb, L.M. Bjursten, H. van der Heyde, and S. Jin, Acta Biomater. 5, 3215 (2009).

A. Pozio, A. Palmieri, A. Girardi, F. Cura, and F. Carinci, Dental Res. J. 9, 5 (2012).

M.S. Aw, K.A. Khalid, K. Gulati, G.J. Atkins, P. Pivonka, D.M. Findlay, and D. Losic, Int. J. Nanomed. 7, 10 (2012).

A. Hamlekhan, A. Butt, S. Patel, D. Royhman, C. Takoudis, C. Sukotjo, J. Yuan, G. Jursich, M.T. Mathew, W. Hendrickson, A. Virdi, and T. Shokuhfar, Plos One 9, 10 (2014).

S.B. Patel, A. Hamlekhan, D. Royhman, A. Butt, J. Yuan, T. Shokuhfar, C. Sukotjo, M.T. Mathew, G. Jursich, and C.G. Takoudis, J. Mater. Chem. B 2, 3597 (2014).

W. Yu, J. Qui, L. Xu, and F. Zhang, Biomed. Mater. 4, 7 (2009).

J.C. Grotberg, Modifying Ti6Al4V Implant Surfaces: Cell Responses and Corrosion Resistance of Annealed Titania Nanotubes.Bioengineering (Chicago: University of Illinois at Chicago, 2014), p. 115.

H. Hirakata, K. Ito, A. Yonezu, H. Tsuchiya, S. Fujimoto, and K. Minoshima, Acta Mater. 58, 4956 (2010).

G.A. Crawford, N. Chawla, and J.E. Houston, J. Mechan. Behav. Biomed. Mater. 2, 580 (2009).

G.A. Crawford, N. Chawla, K. Das, S. Bose, and A. Bandyopadhyay, Acta Biomater. 3, 359 (2007).

C.R. Friedrich, M.K.T. Moser, C. Sujotjo, and T. Shokuhfar, Surf. Innovat. 1, 9 (2013).

T. Shokuhfar, G.K. Arumugam, P.A. Heiden, R.S. Yassar, and C. Friedrich, ACS Nano 3, 3098 (2009).

C.N. Elias, F.A. Rocha, A.L. Nascimento, P.G. Coelho, and J. Mechan, Behav. Biomed. Mater. 16, 169 (2012).

S. Patel, A. Butt, Q. Tao, A.J.I. Rossero, D. Royhman, C. Sukotjo, and C.G. Takoudis, Coll. Surf. B 115, 280 (2014).

D.H. Shin, T. Shokuhfar, C.K. Choi, S.H. Le, and C. Friedrich, Nanotechnology 22, 315704 (2011).

S. Hosseini, Biomedical Engineering-Technical Applications in Medicine (Rijeka: Intech Publications, 2012), p. 18.

P.A. Dearnley, K.L. Dahm, and H. Çimenoğlu, Wear 256, 469 (2004).

T. Cheng, Y. Chen, and X. Nie, Thin Solid Films 549, 123 (2013).

A. Tabassum, F. Walboomers, J.G. Wolke, G.J. Meijer, and J.A. Jansen, Clin. Impl. Dent. Related Res. 13, 269 (2011).

A. Tabassum, F. Walboomers, J.G. Wolke, G.J. Meijer, and J.A. Jansen, Clin. Oral Implants Res. 20, 327 (2009).

M.V. dos Santos, C.N. Elias, and J.H. Cavalcanti Lima, Clin. Impl. Dent. Related Res. 13, 215 (2011).

F. Javed and G.E. Romanos, J. Dent. 38, 612 (2010).

L.H.B. Walschot, Orthopaedics (Nijmegen: Radboud University, 2014), p. 208.

S.J. Ferguson, U. Weber, B. von Rechenberg, and J. Mayer, J. Biomed. Mater. Res. B 77B, 13 (2005).

L.R. VanSchoiack, J.C. Wu, C.G. Sheets, and J.C. Earthman, Mater. Sci. Eng. C 26, 1307 (2006).

R.I.K. Huiskes, H. Weinans, and B.V. Rietbergen, Clin. Orthopaed. Related Res. 274, 124 (1992).

U. Meyer, B. Kruse-Lösler, and H.P. Wiesmann, British J. Oral Maxillofac. Surg. 44, 289 (2006).

D.B. Jones, H. Nolte, J.G. Scholubbers, E. Turner, and D. Veltel, Biomaterials 12, 101 (1991).

V. Swaminathan and J.L. Gilbert, Biomaterials 33, 5487 (2012).

D. O’Sullivan, L. Sennerby, D. Jagger, and N. Meredith, Clin. Impl. Dent. Related Res. 6, 48 (2004).

B.S. Sotto-Maior, E.P. Rocha, E.O. de Almeida, A.C. Freitas-Junior, R.B. Anchieta, and A. Del Bel Cury, Brazilian Dent. J. 21, 508 (2010).

R.J. Marshall (M.Sci. thesis, Saint Louis University, 2010), 81.

G. Augustin, T. Zigman, S. Davila, T. Udilljak, T. Staroveski, D. Brezak, and S. Babic, Clin. Biomechan. 27, 313 (2012).

“Bone Materials,” Pacific Research Laboratories (2013), http://www.sawbones.com/Content/MU_Home.

Acknowledgements

The authors would like to thank Maria Runa for the surface roughness measurements performed in Dr. Wimmers’ Tribology lab at Rush University Medical Center, and Eric Schmidt and Isabella Vieira Marques for Ti-V rod sample preparation. The financial support was provided by the Department of Mechanical Engineering at MTU, and the mechanical tests were conducted in the Biomechanics Research Laboratory at UIC.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Patel, S., Solitro, G.F., Sukotjo, C. et al. Nanotopography and Surface Stress Analysis of Ti6Al4V Bioimplant: An Alternative Design for Stability. JOM 67, 2518–2533 (2015). https://doi.org/10.1007/s11837-015-1341-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1341-8