Abstract

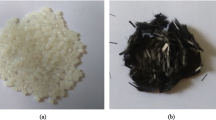

Although the applications of nanotechnologies are increasing, there remains a significant barrier between nanotechnology and machine element applications. This work aims to remove this barrier by blending carbon nanotubes (CNT) with common types of acetal polymer gears (spur, helical, bevel and worm). This was done by using adhesive oil (paraffin) during injection molding to synthesize a flange and short bars containing 0.02% CNT by weight. The flanges and short bars were machined using hobbing and milling machines to produce nanocomposite polymer gears. Some defects that surfaced in previous work, such as the appearance of bubbles and unmelted pellets during the injection process, were avoided to produce an excellent dispersion of CNT in the acetal. The wear resistances of the gears were measured by using a TS universal test rig using constant parameters for all of the gears that were fabricated. The tests were run at a speed of 1420 rpm and a torque of 4 Nm. The results showed that the wear resistances of the CNT/acetal gears were increased due to the addition of CNT, especially the helical, bevel and worm gears.

Similar content being viewed by others

References

A.R. Breeds, S.N. Kukureka, K. Mao, D. Walton, and C.J. Hooke, Wear 166, 85 (1993).

C.J. Hooke, K. Mao, and D. Walton, J. Tribol. 115, 119 (1993).

K. Mao, C.J. Hooke, and D. Walton, Synth. Lubr. 12, 337 (1995).

C.J. Hooke, K. Mao, and D. Walton, J. Tribol. 115, 119 (1993).

K. Mao, Wear 262, 432 (2007).

K.D. Dearn and D. Walton, in Proceedings of the World Congress on Engineering, vol II WCE, London, U.K., 1–3 July 2009

Du Pont (UK) Limited. Herts, UK, 2007.

Victrex PLC. Lancashire, UK, 2009.

Hayrettin Duzcukoglu, Mater. Des. 30, 1060 (2009).

H. Meng, G.X. Sui, G.Y. Xie, and R. Yang, Compos. Sci. Technol. 69, 606 (2009).

S. Yousef, A. Khattab, M. Zak, and T.A. Osman, IEEE Trans. Nanotechnol. 12, 616 (2013).

S. Yousef, T.A. Osman, M. Khattab, A.A. Bahr, and A.M. Youssef, Friction (under review)

S. Yousef, A. Khattab, T.A. Osman, and M. Zaki, J. Nanomater. (2013). doi:10.1155/2013/392126

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yousef, S., Osman, T.A., Abdalla, A.H. et al. Wear Characterization of Carbon Nanotubes Reinforced Acetal Spur, Helical, Bevel and Worm Gears Using a TS Universal Test Rig. JOM 67, 2892–2899 (2015). https://doi.org/10.1007/s11837-014-1268-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1268-5