Abstract

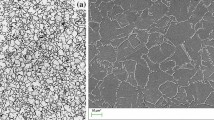

The shot-peening process is currently employed in most industries to improve the longevity of components by inhibiting crack initiation as well as crack growth at the surface. The protective effect of shot peening has been mainly attributed to compressive stresses within the deformed layer. Intensive research has been carried out to quantify the near-surface residual stresses on entry into service and evolution throughout life. In nickel-base superalloys, the focus of research on the effects of shot-peening has performed using x-rays from either laboratory or synchrotron-based sources. However, this approach cannot evaluate in detail the deformation mechanisms nor the role of the γ′ precipitates in a nickel-base superalloy; the latter is responsible for its unique properties. Our study uses a complementary range of techniques to investigate in detail the microstructure and deformation mechanisms associated with shot-peening in a coarse-grained nickel-based superalloy strengthened with coherent γ′ precipitates. These include scanning electron microscopy and transmission electron microscopy, nanoindentation and micropillar compression. Accurate mapping of the dislocation structure produced throughout the deformed layers have been performed. Using an unconventional specimen preparation technique, it provides the basis for a more complete interpretation of how shot-peening inhibits fatigue cracking.

Similar content being viewed by others

References

R.L. Barrie, T.P. Gabb, J. Telesman, and P.T. Kantzos, Effectiveness of Shot Peening in Suppressing Fatigue Cracking at Non-Metallic Inclusions in Udimet™ 720 (Cleveland, OH: NASA, 2005).

R.L. Barrie, T.P. Gabb, J. Telesman, P.T. Kantzos, A. Prescenzi, T. Biles, and P.J. Bonacuse, Mater. Sci. Eng. A 474, 71 (2008).

W.Z. Zhuang and G.R. Halford, Int. J. Fatigue 23, S31 (2001).

D.J. Buchanan, R. John, and R.A. Brockman, J. Eng. Mater. Technol. 131, 031008 (2009).

D.J. Buchanan, R. John, and R.A. Brockman, Superalloys 2008, ed. R.C. Reed, K.A. Green, P. Caron, T.P. Gabb, M.G. Fahrmann, E.S. Huron, and S.A. Woodard (Warrendale, PA: TMS, 2008), pp. 965–974.

P.J. Withers, Rep. Prog. Phys. 70, 2211 (2007).

S.B. Kim, J. Shackleton, M. Preuss, P.J. Withers, A. Evans, and G. Bruno, Metall. Mater. Trans. A 36, 3041 (2005).

A. Evans, S. Kim, J. Shackleton, G. Bruno, M. Preuss, and P. Withers, Int. J. Fatigue 27, 1530 (2005).

R. John, D.J. Buchanan, M.J. Caton, and S.K. Jha, Proc. Eng. 2, 1887 (2010).

W. Cao, M. Khadhraoui, and B. Brenier, Mater. Sci. Technol. 10, 947 (1994).

W.C. Liu, J. Dong, P. Zhang, A.M. Korsunsky, X. Song, and W.J. Ding, Mater. Sci. Eng. A 528, 5935 (2011).

P. Juijerm, U. Noster, I. Altenberger, and B. Scholtes, Mater. Sci. Eng. A 379, 286 (2004).

P. Prevéy, D. Hombach, and P. Mason, in Proceedings of the 17th Heat Treating Society Conference and Exposition and the 1st International Induction Heat Treating Symposium, ed. by D.L. Milam (Materials Park, OH, ASM, 1998), pp. 3–12

I. Altenberger, B. Scholtes, U. Martin, and H. Oettel, Mater. Sci. Eng. A 264, 1 (1999).

U. Martin, I. Altenberger, B. Scholtes, K. Kremmer, and H. Oettel, Mater. Sci. Eng. A 246, 69 (1998).

U. Martin, I. Altenberger, B. Scholtes, K. Kremmer, and H. Oettel, Unpublished Research (1996)

A.L. Ortiz, J.W. Tian, J.C. Villegas, L.L. Shaw, and P.K. Liaw, Acta Mater. 56, 413 (2008).

L.L. Shaw, J. Villegas, J.-Y. Huang, and S. Chen, Mater. Sci. Eng. A 480, 75 (2008).

L.L. Shaw, J.-W. Tian, A.L. Ortiz, K. Dai, J.C. Villegas, P.K. Liaw, R. Ren, and D.L. Klarstrom, Mater. Sci. Eng. A 527, 986 (2010).

J.C. Villegas, L.L. Shaw, K. Dai, W. Yuan, J. Tian, P.K. Liaw, and D.L. Klarstrom, Phil. Mag. Lett. 85, 427 (2005).

D.J. Child, G.D. West, and R.C. Thomson, Acta Mater. 59, 4825 (2011).

R.J. Mitchell, J.A. Lemsky, R.R, H.Y. Li, L. Connor, and K.M. Perkins, in Superalloys 2008 (Warrendale, PA, TMS, 2008), pp. 347–356

L. Connor (Ph.D. dissertation, University of Cambridge, Cambridge, UK, 2009)

A. Manning, D. Knowles, and C. Small, European Patent Office (2002)

E. Limpert, W.A. Stahel, and M. Abbt, BioScience (2001)

B.J. Foss, S. Gray, M.C. Hardy, S. Stekovic, D.S. McPhail, and B.A. Shollock, Acta Mater. 61, 2548 (2013).

O.M.D.M. Messé, S. Stekovic, M. Hardy, and C.M.F. Rae, Adv. Mater. Res. 891–892, 1289 (2014).

S. Korte, R.J. Stearn, J.M. Wheeler, and W.J. Clegg, J. Mater. Res. 27, 167 (2011).

S.B. Kim, A. Evans, J. Shackleton, G. Bruno, M. Preuss, and P.J. Withers, Metall. Mater. Trans. A 36A, 3041 (2005).

H. Holzapfel, V. Schulze, and O. Vohringer, Mater. Sci. Eng. A 1998.

S. Cruchley, M.P. Taylor, H.E. Evans, P. Bowen, M.C. Hardy, and S. Stekovic, Superalloys 2012, eds. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, and J. Telesman (Hoboken, NJ: Wiley, 2012), pp. 751–758.

Acknowledgements

The authors would like to acknowledge the efforts of the EPSRC, Rolls-Royce plc. for their financial support in the completion of this work (EPSRC and Rolls-Royce Strategic Partnership: EP/H500375/1 and EP/H022309 and the TSB project SILOET TP number: AB266C/4). Rolls-Royce plc. is also gratefully acknowledged for supplying the material. The authors would also like to thank Dr. Claudia Walter for the introduction to FIB scripting that enabled the production of micropillars and subsequent compression.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Messé, O.M.D.M., Stekovic, S., Hardy, M.C. et al. Characterization of Plastic Deformation Induced by Shot-Peening in a Ni-Base Superalloy. JOM 66, 2502–2515 (2014). https://doi.org/10.1007/s11837-014-1184-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1184-8