Abstract

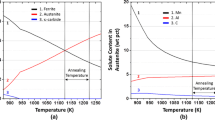

Concepts of Fe-Al-Mn-C-based lightweight steels are fairly simple, but primary metallurgical issues are complicated. In this study, recent studies on lean-composition lightweight steels were reviewed, summarized, and emphasized by their microstructural development and mechanical properties. The lightweight steels containing a low-density element of Al were designed by thermodynamic calculation and were manufactured by conventional industrial processes. Their microstructures consisted of various secondary phases as κ-carbide, martensite, and austenite in the ferrite matrix according to manufacturing and annealing procedures. The solidification microstructure containing segregations of C, Mn, and Al produced a banded structure during the hot rolling. The (ferrite + austenite) duplex microstructure was formed after the annealing, and the austenite was retained at room temperature. It was because the thermal stability of austenite nucleated from fine κ-carbide was quite high due to fine grain size of austenite. Because these lightweight steels have outstanding properties of strength and ductility as well as reduced density, they give a promise for automotive applications requiring excellent properties.

Similar content being viewed by others

References

M. Ritzkowski and R. Stegmann, Int. J. Greenh. Gas Control 1, 281 (2007).

K. Kaygusuz, Renew. Sustain. Energy Rev. 13, 253 (2009).

K. Hashimoto, M. Yamasaki, K. Fujimura, T. Matsui, K. Izumiya, M. Komori, A.A. El-Moneim, E. Akiyama, H. Habazaki, N. Kumagai, A. Kawashima, and K. Asami, Mater. Sci. Eng. A 267, 200 (1999).

P.J. Jacques, Curr. Opin. Solid State Mater. Sci. 8, 259 (2004).

S. Zaefferer, J. Ohlert, and W. Bleck, Acta Mater. 52, 2765 (2004).

I.B. Timokhina, P.D. Hodgson, and E.V. Pereloma, Metall. Mater. Trans. A 35A, 2331 (2004).

D.K. Matlock and J.G. Speer, Mater. Manuf. Processes 25, 7 (2010).

H. Kim, D.-W. Suh, and N.J. Kim, Sci. Technol. Adv. Mater. 14, 1 (2013).

L. Falat, A. Schneider, G. Sauthoff, and G. Frommeyer, Intermetallics 13, 1256 (2005).

R. Rana, C. Liu, and R.K. Ray, Scripta Mater. 68, 354 (2013).

D.-W. Suh, S.-J. Park, T.-H. Lee, C.S. Oh, and S.J. Kim, Metall. Mater. Trans. A 41, 397 (2010).

S.-J. Park, B. Hwang, K.H. Lee, T.-H. Lee, D.-W. Suh, and H.N. Han, Scripta Mater. 68, 365 (2012).

K. Choi, C.H. Seo, H. Lee, S.K. Kim, J.H. Kwak, K.G. Chin, K.T. Park, and N.J. Kim, Scripta Mater. 63, 1028 (2010).

G. Frommeyer, U. Brüx, and P. Neumann, ISIJ Int. 43, 438 (2003).

C.H. Seo, K.H. Kwon, K. Choi, K.H. Kim, J.H. Kwak, S. Lee, and N.J. Kim, Scripta Mater. 66, 519 (2012).

H. Springer and D. Raabe, Acta Mater. 60, 4950 (2012).

R.G. Baligidad, U. Prakash, and A. Radhakrishna, Scripta Mater. 36, 667 (1997).

K.-T. Park, Scripta Mater. 68, 375 (2013).

J.-E. Jin and Y.-K. Lee, Acta Mater. 60, 1680 (2012).

H.-J. Lee, S.S. Sohn, S. Lee, J.-H. Kwak, and B.-J. Lee, Scripta Mater. 68, 339 (2013).

B. Sundman, B. Jansson, and J.-O. Andersson, CALPHAD 9, 153 (1985).

TCFE2000: The Thermo-Calc Steels Database, upgraded by B.-J. Lee, B. Sundman at KTH, KTH, Stockholm, 1999.

K.-G. Chin, H.-J. Lee, J.-H. Kwak, J.-Y. Kang, and B.-J. Lee, J. Alloy Compd. 505, 217 (2010).

A. Piñol-Juez, A. Iza-mendia, and I. Gutiérrez, Metall. Mater. Trans. A 31A, 1671 (2000).

N. Suutala, T. Takalo, and T. Moisio, Metall. Trans. A 11A, 717 (1980).

S. Atamert and J.E. King, Acta Metall. Mater. 39, 273 (1991).

S.Y. Shin, H. Lee, S.Y. Han, C.-H. Seo, K. Choi, S. Lee, N.J. Kim, J.-H. Kwak, and K.-G. Chin, Metall. Mater. Trans. A 41A, 138 (2010).

C.Y. Chao and T.F. Liu, Metall. Trans. A 23A, 1957 (1993).

P. Kratochvíl, Intermetallics 17, 39 (2009).

J.-B. Seol, D. Raabe, P. Choi, H.-S. Park, J.-H. Kwak, and C.-G. Park, Scripta Mater. 68, 348 (2013).

W.K. Choo, J.H. Kim, and J.C. Yoon, Acta Mater. 45, 4877 (1997).

K. Ishida, H. Ohtani, N. Satoh, R. Kainuma, and T. Nishizawa, ISIJ Int. 30, 680 (1990).

Y. Kimura, K. Handa, K. Hayashi, and Y. Mishima, Intermeallics 12, 607 (2004).

D.C. van Aken, Missouri University of Science and Technology, Private Communication (2012)

M.R. Berrahmoune, S. Berveiller, K. Inal, A. Moulin, and E. Patoor, Mater. Sci. Eng. A 378, 304 (2004).

S. Takaki, K. Fukunaga, J. Syarif, and T. Tsuchiyama, Mater. Trans. 45, 2245 (2004).

Y.-S. Jung, Y.-K. Lee, D.K. Matlock, and M.C. Mataya, Metall. Mater. Int. 17, 553 (2011).

J. Mahieu, J. Maki, B.C. De Cooman, and S. Claessens, Metall. Mater. Trans. A 33A, 2573 (2002).

E. Jimenez-Melero, N.H. van Dijk, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, and S. van der Zwaag, Acta Mater. 53, 5439 (2005).

S.S. Sohn, B.-J. Lee, S. Lee, N.J. Kim, and J.-H. Kwak, Acta Mater. 61, 5050 (2013).

M. Calcagnotto, D. Ponge, and D. Raabe, Metall. Mater. Trans. A 43A, 37 (2012).

Acknowledgements

This work was supported by the Ministry of Knowledge Economy under a Grant No. 10031723-2011-21. The authors would like to thank Mr. Hyuk-Joong Lee of POSTECH for his help with the correlation between alloying effects and microstructural developments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sohn, S.S., Lee, S., Lee, BJ. et al. Microstructural Developments and Tensile Properties of Lean Fe-Mn-Al-C Lightweight Steels. JOM 66, 1857–1867 (2014). https://doi.org/10.1007/s11837-014-1128-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1128-3