Abstract

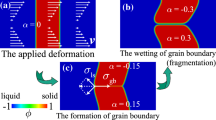

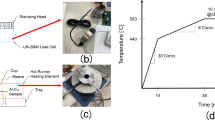

Deformation of the semisolid mush during solidification is a common phenomenon in metal casting and can lead to defects such as hot tears, macrosegregation, and porosity. The morphology of the solidifying mush, including the shape of the dendrites and the distribution of grain boundaries, plays a key role in determining its mechanical behavior. In the current study, a polycrystalline phase-field model is combined with a material point method stress analysis to numerically simulate the fully coupled dendritic solidification and elasto-viscoplastic deformation behavior of a pure substance in two dimensions. It is shown that solid compressive and shear deformations result in variations in the crystallographic orientation angle within a single dendrite that, in turn, affect the subsequent solidification behavior. Shearing of a dendritic structure occurs primarily in relatively narrow bands near or inside the grain boundaries or the thin junctions between different dendrite arms. The deformations can cause the formation of low-angle tilt grain boundaries inside of individual dendrite arms. In addition, grain boundaries form when different arms of a deformed single dendrite impinge. During compression of a high-solid-fraction dendritic structure, the deformations are limited to a relatively thin layer along the compressing boundary. The compression causes consolidation of this layer into a fully solid structure that consists of numerous subgrains.

Similar content being viewed by others

References

J.A. Dantzig and M. Rappaz, Solidification (Lausanne, Switzerland: EPFL Press, 2009).

M. Flemings, Metall. Mater. Trans. B 22, 269 (1991).

M.G. Pokorny, C.A. Monroe, C. Beckermann, Z. Zhen, and N. Hort, Metall. Mater. Trans. A 41A, 3196 (2010).

A.B. Phillion, S.L. Cockcroft, and P.D. Lee, Acta Mater. 56, 4328 (2008).

D. Fuloria and P.D. Lee, Acta Mater. 57, 5554 (2009).

T. Uehara, M. Fukui, and N. Ohno, J. Cryst. Growth 310, 1331 (2008).

I. Farup, J.M. Drezet, and M. Rappaz, Acta Mater. 49, 1261 (2001).

S. Terzi, Scripta Mater. 61, 449 (2009).

M. Sistaninia, A.B. Phillion, J.M. Drezet, and M. Rappaz, Metall. Mater. Trans. A 42A, 239 (2011).

M. Yamaguchi and C. Beckermann, Acta Mater. 61, 4053 (2013).

M. Yamaguchi and C. Beckermann, Acta Mater. 61, 2268 (2013).

J.A. Warren, R. Kobayashi, A.E. Lobkovsky, and W.C. Carter, Acta Mater. 51, 6035 (2003).

D. Sulsky, Z. Chen, and H.L. Schreyer, Comput. Methods Appl. Mech. Eng. 118, 179 (1994).

R. Kobayashi and J.A. Warren, Physica A 356, 127 (2005).

A. Gilmanov and S. Acharya, Int. J. Numer. Methods Fluid 56, 2151 (2008).

C. Beckermann, H.J. Diepers, I. Steinbach, A. Karma, and X. Tong, J. Comput. Phys. 154, 468 (1999).

Y. Sun and C. Beckermann, Physica D 198, 281 (2004).

Y. Sun and C. Beckermann, Physica D 237, 3089 (2008).

Acknowledgements

This work was financially supported, in part, by NASA under Grant Number NNX10AV35G.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamaguchi, M., Beckermann, C. Direct Numerical Simulation of Solid Deformation During Dendritic Solidification. JOM 66, 1431–1438 (2014). https://doi.org/10.1007/s11837-014-1001-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1001-4